Table of Contents

Benefits of Using HDPE Injection Blow Molding Machine

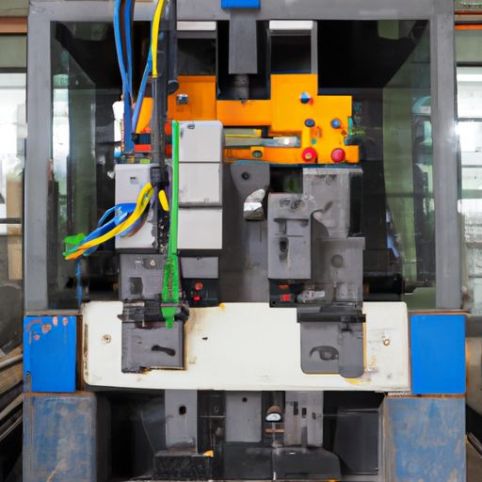

Injection blow molding is a manufacturing process used to produce hollow plastic parts. This process involves injecting molten plastic into a mold cavity, where it is then blown into the desired shape using compressed air. One type of injection blow molding machine that is commonly used is the HDPE injection blow molding machine. This machine is specifically designed to work with high-density polyethylene (HDPE) plastic, which is a versatile material known for its strength, durability, and resistance to Chemicals and moisture.

One of the key benefits of using an HDPE injection blow molding machine is its ability to produce high-quality, uniform parts with tight tolerances. This machine is equipped with advanced technology that allows for precise control over the injection and blowing processes, resulting in consistent part dimensions and wall thicknesses. This level of precision is essential for ensuring the structural integrity and performance of the final product.

Another advantage of using an HDPE injection blow molding machine is its efficiency and cost-effectiveness. This machine is capable of producing large quantities of parts in a relatively short amount of time, making it ideal for high-volume production runs. Additionally, the use of HDPE plastic can help reduce material waste and energy consumption, further lowering production costs.

Furthermore, HDPE injection blow molding machines are versatile and can be used to produce a wide range of products, including bottles, Containers, and automotive components. The flexibility of this machine allows manufacturers to easily switch between different molds and production runs, making it a valuable asset for businesses looking to diversify their product offerings.

In addition to its efficiency and versatility, the use of an HDPE injection blow molding machine can also Lead to improved product quality. HDPE plastic is known for its excellent chemical resistance and low moisture absorption, making it an ideal material for applications where durability and reliability are essential. Parts produced using this machine are less likely to warp, crack, or degrade over time, ensuring a longer lifespan and better performance for end-users.

Overall, the benefits of using an HDPE injection blow molding machine are clear. From its ability to produce high-quality, uniform parts to its efficiency and cost-effectiveness, this machine offers numerous advantages for manufacturers looking to streamline their production processes and improve the quality of their products. By investing in an HDPE injection blow molding machine, businesses can stay competitive in today’s fast-paced market and meet the growing demand for high-quality Plastic Products.

Tips for Choosing a Used Plastic Injection Molding Machine

When it comes to choosing a used plastic injection molding machine, there are several factors to consider in order to ensure that you are making a wise investment. These machines can be a significant expense, so it is important to do your research and make an informed decision. Here are some tips to help guide you through the process.

First and foremost, it is essential to consider the type of material that you will be working with. Different materials require different types of Injection Molding Machines, so it is important to choose a machine that is compatible with the material you will be using. For example, if you will be working with high-density polyethylene (HDPE), you will need a machine that is specifically designed for this type of material.

In addition to considering the type of material, you should also think about the size and shape of the parts that you will be producing. Different injection molding machines have different capabilities in terms of the size and complexity of the parts that they can produce. Make sure to choose a machine that is capable of meeting your specific production needs.

Another important factor to consider when choosing a used plastic injection molding machine is the brand and model of the machine. Some brands are known for their reliability and durability, while others may have a reputation for being less reliable. Do your research and read reviews from other users to get a sense of the quality of the machine you are considering.

Another important factor to consider when choosing a used plastic injection molding machine is the brand and model of the machine. Some brands are known for their reliability and durability, while others may have a reputation for being less reliable. Do your research and read reviews from other users to get a sense of the quality of the machine you are considering.

It is also important to consider the age and condition of the machine. While older machines may be more affordable, they may also be more prone to breakdowns and require more maintenance. On the other hand, newer machines may be more reliable but come with a higher price tag. Consider your budget and production needs when deciding on the age and condition of the machine.

When purchasing a used plastic injection molding machine, it is also important to consider the seller. Make sure to buy from a reputable seller who has a good track record of selling quality machines. Ask for references and check online reviews to ensure that you are dealing with a trustworthy seller.

Finally, before making a purchase, it is a good idea to inspect the machine in person if possible. Look for signs of wear and tear, such as rust or corrosion, and test the machine to ensure that it is in good working condition. If you are not familiar with injection molding machines, consider bringing along a knowledgeable friend or hiring a professional to inspect the machine for you.

In conclusion, choosing a used plastic injection molding machine requires careful consideration of several factors, including the type of material, size and shape of parts, brand and model, age and condition, seller reputation, and machine inspection. By taking the time to research and evaluate these factors, you can make an informed decision and choose a machine that will meet your production needs and provide reliable performance for years to come.