Table of Contents

Exploring the Highneck Sweater Production Process in Chinese Manufacturing Plants

The highneck sweater, a staple in many Wardrobes, is a testament to the ingenuity and craftsmanship of the textile industry. A significant portion of these garments are produced in China, a global leader in textile manufacturing. The process of highneck sweater production in Chinese manufacturing plants is a fascinating blend of traditional techniques and modern technology, resulting in high-quality, stylish garments known as Sweaters chompas.

The journey of a highneck sweater begins with the selection of raw materials. Chinese manufacturers often opt for a blend of natural and synthetic fibers to achieve the desired texture, durability, and warmth. Wool, cotton, and polyester are commonly used, each contributing unique properties to the final product. The raw materials are then cleaned, carded, and spun into Yarn, a process that requires meticulous attention to detail to ensure consistency and quality.

Once the yarn is prepared, it is dyed to the desired color. This stage involves a complex chemical process, with the dye carefully chosen to ensure colorfastness and resistance to fading. The dyed yarn is then dried and wound onto cones, ready for the knitting process.

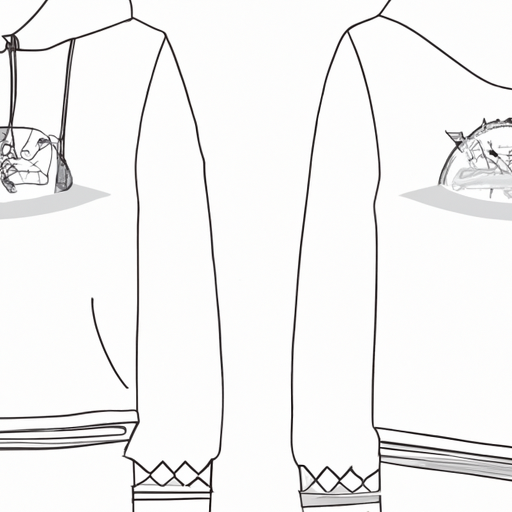

The knitting stage is where the highneck sweater begins to take shape. Modern Chinese manufacturing plants utilize computerized Knitting Machines, which can produce intricate patterns and designs with precision and speed. These machines follow pre-programmed instructions to knit the yarn into panels for the front, back, and Sleeves of the sweater. The highneck collar, a defining feature of the sweater, is also knitted during this stage.

| Serial Number | Product | Fabric variety | Supply model |

| 1. | sweaters baby | LUREX | Sweater Tailor-made |

Once the panels are knitted, they are inspected for any defects or inconsistencies. This quality control step is crucial in maintaining the high standards associated with Chinese textile manufacturing. Any panels that do not meet the required standards are discarded, ensuring that only the best quality pieces proceed to the next stage.

The approved panels are then sent to the linking department, where they are assembled into a complete sweater. This process is typically done by skilled workers who manually link the panels together using a linking machine. The highneck collar is attached at this stage, and any additional features such as zippers or Buttons are also added.

The assembled sweaters are then washed and dried to remove any residual dye or Chemicals from the manufacturing process. This step also helps to soften the fabric and enhance its comfort. After washing, the sweaters are pressed to remove any wrinkles and give them a neat, finished appearance.

The final stage in the production process is quality control. Each highneck sweater is thoroughly inspected for any defects or inconsistencies. This includes checking the seams, the fit of the collar, and the overall appearance of the sweater. Only those that pass this rigorous inspection are approved for sale.

In conclusion, the production of highneck sweaters in Chinese manufacturing plants is a complex process that combines traditional craftsmanship with modern technology. The result is a high-quality, stylish garment that is a testament to the skill and dedication of the Chinese textile industry. Whether worn for warmth or style, the highneck sweater is a product of meticulous attention to detail and a commitment to quality that is evident in every stitch.