Table of Contents

Benefits of Using Galvanized ERW Steel Pipe for Fire Protection

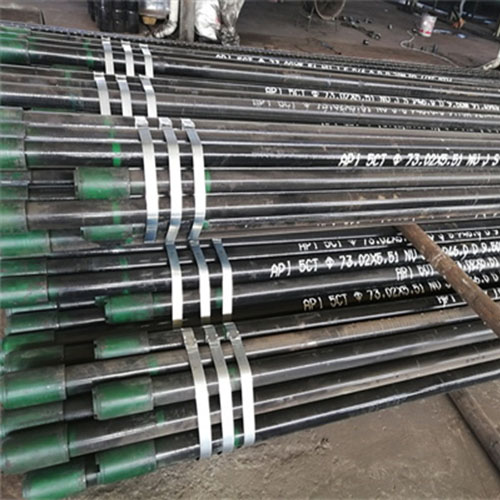

Galvanized ERW Steel Pipes are a popular choice for fire protection systems due to their durability, strength, and corrosion resistance. These pipes are manufactured using the Electric Resistance Welding (ERW) process, which involves the welding of the seams of the pipe using high-frequency electrical currents. The resulting pipe is strong, seamless, and resistant to leaks, making it an ideal choice for fire protection applications.

One of the key benefits of using galvanized ERW steel pipes for fire protection is their resistance to corrosion. The galvanization process involves coating the steel pipe with a layer of Zinc, which acts as a barrier against corrosion and rust. This protective layer ensures that the pipe remains in good condition even when exposed to harsh environmental conditions, such as high humidity or corrosive Chemicals. As a result, galvanized ERW steel pipes have a longer lifespan compared to other types of pipes, reducing the need for frequent maintenance and replacement.

In addition to their corrosion resistance, galvanized ERW steel pipes are also highly durable and strong. The welding process used to manufacture these pipes creates a seamless and uniform structure that can withstand high pressure and temperature fluctuations. This makes galvanized ERW steel pipes an excellent choice for fire protection systems, where reliability and performance are crucial. These pipes can safely transport water or other fire suppression agents to the desired location without the risk of leaks or failures, ensuring that the fire protection system operates effectively in case of an emergency.

Furthermore, galvanized ERW steel pipes are easy to install and maintain, making them a cost-effective choice for fire protection applications. The lightweight nature of these pipes allows for quick and efficient installation, reducing labor costs and downtime. Additionally, the smooth surface of galvanized ERW steel pipes minimizes friction and pressure loss, ensuring efficient flow of water or fire suppression agents through the system. This not only improves the overall performance of the fire protection system but also reduces energy consumption and operational costs.

Another advantage of using galvanized ERW steel pipes for fire protection is their versatility and adaptability. These pipes come in a variety of sizes and thicknesses, allowing for customization to meet the specific requirements of the project. Whether it is a small residential building or a large industrial complex, galvanized ERW steel pipes can be tailored to fit the unique needs of the fire protection system. Additionally, these pipes can be easily connected to other components, such as Valves, fittings, and sprinkler heads, to create a comprehensive and reliable fire protection network.

In conclusion, galvanized ERW steel pipes offer numerous benefits for fire protection systems, including corrosion resistance, durability, strength, ease of installation, and versatility. These pipes provide a reliable and cost-effective solution for ensuring the Safety and Security of buildings and occupants in case of a fire emergency. By choosing galvanized ERW steel pipes for fire protection applications, property owners and Developers can rest assured that their fire protection system is built to last and perform at its best when needed.

Proper Installation Techniques for Welding Removed Galvanized ERW Steel Pipe

Proper installation techniques are crucial when it comes to welding removed galvanized ERW steel pipe for fire protection systems. This type of pipe is commonly used in commercial and industrial settings to transport water, gas, or other fluids. It is important to follow specific guidelines to ensure the safety and effectiveness of the system.

One of the first steps in the installation process is to properly prepare the pipe for welding. This includes removing any galvanized coating from the area where the weld will be made. The galvanized coating can release toxic fumes when heated, so it is essential to remove it before welding. This can be done using a wire brush or grinder to strip away the coating.

Once the galvanized coating has been removed, the next step is to properly align the pipes for welding. It is important to ensure that the pipes are straight and level to prevent any leaks or weak spots in the weld. This can be done using a level and measuring tape to ensure accuracy.

After the pipes have been aligned, the next step is to tack weld them together. Tack welding involves making small, temporary welds to hold the pipes in place before making the final weld. This helps to ensure that the pipes remain aligned during the welding process. It is important to use the correct welding technique and settings to create strong and durable tack welds.

Once the pipes have been tack welded, the final step is to make the full weld. This involves welding along the entire length of the joint to create a strong and secure connection. It is important to use the correct welding technique and settings to ensure a proper weld. This may involve using a specific type of welding rod or wire, as well as adjusting the heat and speed of the welder.

After the welding process is complete, it is important to inspect the weld for any defects or imperfections. This can be done using a visual inspection or non-destructive testing methods such as ultrasonic testing. Any defects or imperfections should be repaired before the system is put into service to prevent leaks or failures.

In conclusion, proper installation techniques are essential when welding removed galvanized ERW steel pipe for fire protection systems. By following specific guidelines and using the correct welding techniques, you can ensure the safety and effectiveness of the system. It is important to properly prepare the pipe, align the pipes, tack weld, make the final weld, and inspect the weld for defects. By taking these steps, you can create a strong and reliable fire protection system that will provide years of service.