Table of Contents

Benefits of Using GB5310-2009/GB3087-200/ A106 /A53 Gr B Welded Steel Pipe in Piling Projects

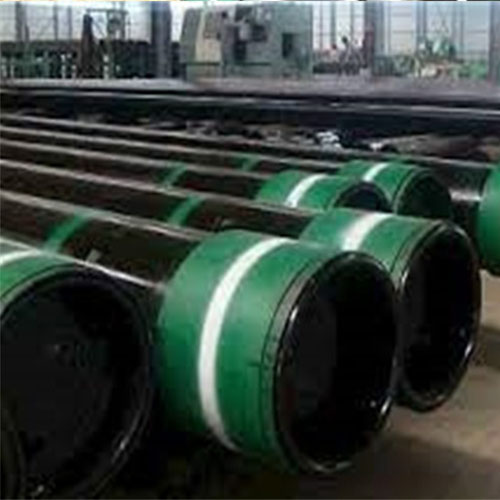

Welded Steel Pipes are a crucial component in various industries, including piling, water, oil, and gas. Among the many options available in the market, GB5310-2009/GB3087-200/ A106 /A53 Gr B welded steel pipes stand out for their exceptional quality and performance. These pipes are specifically designed to meet the demanding requirements of piling projects, offering a range of benefits that make them a preferred choice for contractors and engineers.

One of the key advantages of using GB5310-2009/GB3087-200/ A106 /A53 Gr B welded steel pipes in piling projects is their superior strength and durability. These pipes are made from high-quality materials that are designed to withstand the heavy loads and pressures that are common in piling applications. This means that they can provide reliable support for structures and foundations, ensuring long-term stability and Safety.

In addition to their strength, GB5310-2009/GB3087-200/ A106 /A53 Gr B welded steel pipes are also highly resistant to corrosion and other forms of damage. This makes them ideal for use in environments where exposure to moisture, Chemicals, and other corrosive substances is a concern. By choosing these pipes for piling projects, contractors can ensure that their structures will remain intact and secure for years to come.

Another benefit of using GB5310-2009/GB3087-200/ A106 /A53 Gr B welded steel pipes is their versatility. These pipes are available in a wide range of sizes and specifications, making it easy to find the perfect fit for any piling project. Whether you need a small diameter pipe for a residential foundation or a large diameter pipe for a commercial building, you can trust that GB5310-2009/GB3087-200/ A106 /A53 Gr B welded steel pipes will meet your requirements.

Furthermore, GB5310-2009/GB3087-200/ A106 /A53 Gr B welded steel pipes are easy to install and maintain, saving time and money for contractors and project owners. Their smooth surfaces and precise dimensions make them simple to work with, while their durability ensures that they will require minimal upkeep over their lifespan. This means that piling projects can be completed more efficiently and cost-effectively when using these high-quality pipes.

In conclusion, GB5310-2009/GB3087-200/ A106 /A53 Gr B welded steel pipes are an excellent choice for piling projects in the water, oil, and gas industry. Their strength, durability, corrosion resistance, versatility, and ease of installation make them a reliable and cost-effective option for contractors and engineers. By choosing these pipes for your next piling project, you can ensure that your structures will be built to last and withstand the test of time.

Applications of GB5310-2009/GB3087-200/ A106 /A53 Gr B Welded Steel Pipe in Water, Oil & Gas Industry

GB5310-2009, GB3087-200, A106, and A53 Gr B welded steel pipes are widely used in various industries, including water, oil, and gas. These pipes are known for their durability, strength, and resistance to corrosion, making them ideal for applications in demanding environments.

In the water industry, GB5310-2009, GB3087-200, A106, and A53 Gr B welded steel pipes are commonly used for water supply and drainage systems. These pipes are able to withstand high pressure and are resistant to corrosion, making them a reliable choice for Transporting water over long distances. Additionally, the smooth interior surface of these pipes helps to reduce friction and improve the flow of water, making them an efficient option for water distribution systems.

In the oil industry, GB5310-2009, GB3087-200, A106, and A53 Gr B welded steel pipes are used for transporting Crude Oil and Natural Gas from production sites to refineries and distribution centers. These pipes are able to withstand high temperatures and pressures, making them suitable for the harsh conditions encountered in the oil industry. Additionally, the welded construction of these pipes ensures a tight seal, preventing leaks and ensuring the safe transport of oil and gas.

In the gas industry, GB5310-2009, GB3087-200, A106, and A53 Gr B welded steel pipes are used for transporting natural gas from production sites to distribution centers and end users. These pipes are able to withstand high pressures and are resistant to corrosion, making them a reliable choice for gas distribution systems. Additionally, the welded construction of these pipes ensures a secure connection, reducing the risk of leaks and ensuring the safe transport of natural gas.

Overall, GB5310-2009, GB3087-200, A106, and A53 Gr B welded steel pipes are versatile and reliable options for a wide range of applications in the water, oil, and gas industries. Their durability, strength, and resistance to corrosion make them ideal for use in demanding environments, where reliability and safety are paramount.

In conclusion, GB5310-2009, GB3087-200, A106, and A53 Gr B welded steel pipes are essential components in the water, oil, and gas industries. Their ability to withstand high pressures, temperatures, and corrosive environments make them a reliable choice for transporting water, oil, and gas over long distances. Whether used for water supply and drainage systems, oil and gas transportation, or gas distribution systems, these pipes play a crucial role in ensuring the safe and efficient operation of various industries.