Table of Contents

Benefits of Using 9-5/8 API 5CT Seamless Steel Pipe Casing and Tubing Coupling in Oilfield Operations

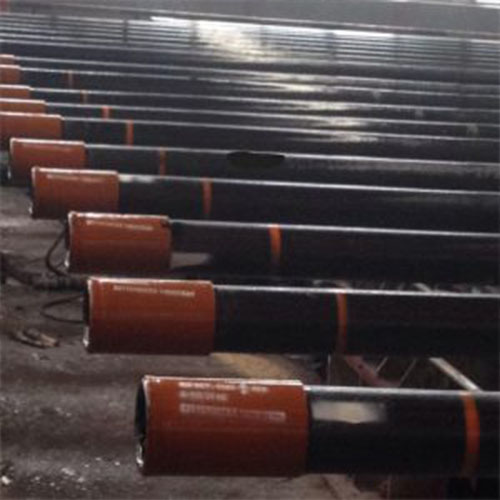

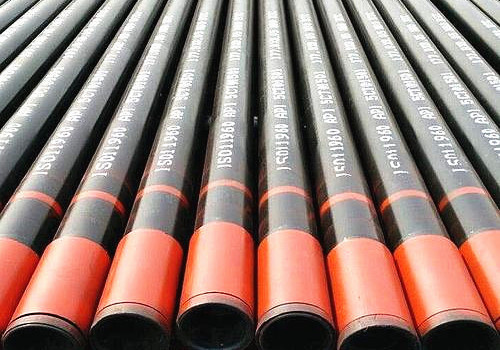

Oilfield operations require durable and reliable equipment to ensure the smooth and efficient extraction of oil and gas. One crucial component in these operations is the casing and tubing coupling used in the drilling process. The 9-5/8″ API 5CT seamless steel pipe casing and tubing coupling is a popular choice among oilfield operators due to its numerous benefits.

One of the key advantages of using the 9-5/8″ API 5CT seamless steel pipe casing and tubing coupling is its high strength and durability. Made from high-quality steel, this coupling can withstand the harsh conditions of the oilfield, including high pressure and extreme temperatures. This durability ensures that the coupling will not fail during the drilling process, reducing the risk of costly downtime and repairs.

In addition to its strength, the 9-5/8″ API 5CT seamless steel pipe casing and tubing coupling also offers excellent corrosion resistance. This is crucial in oilfield operations, where exposure to corrosive substances such as saltwater and Chemicals can cause damage to equipment over time. By using a corrosion-resistant coupling, operators can extend the lifespan of their equipment and reduce maintenance costs.

Furthermore, the seamless design of the 9-5/8″ API 5CT coupling provides a tight and leak-proof connection between the casing and tubing. This ensures that no oil or gas leaks occur during the drilling process, preventing environmental contamination and ensuring compliance with regulations. The seamless design also reduces the risk of weak points in the coupling, further enhancing its reliability and Safety.

Another benefit of using the 9-5/8″ API 5CT seamless steel pipe casing and tubing coupling is its ease of installation. The coupling is designed to be quickly and easily connected to the casing and tubing, reducing the time and labor required for installation. This can help operators save time and money during the drilling process, allowing them to increase efficiency and productivity.

Additionally, the 9-5/8″ API 5CT seamless steel pipe casing and tubing coupling is compatible with a wide range of drilling equipment, making it a versatile choice for oilfield operations. Whether used in vertical, directional, or horizontal drilling, this coupling can provide a reliable connection between the casing and tubing, ensuring smooth and efficient operations.

Overall, the 9-5/8″ API 5CT seamless steel pipe casing and tubing coupling offers numerous benefits for oilfield operators. From its high strength and durability to its corrosion resistance and ease of installation, this coupling is a reliable and cost-effective choice for drilling operations. By choosing the 9-5/8″ API 5CT coupling, operators can ensure the safety, efficiency, and success of their oilfield operations.

How to Properly Install and Maintain 9-5/8 API 5CT Seamless Steel Pipe Casing and Tubing Coupling in Oilfield Applications

9-5/8″ API 5CT seamless steel pipe casing and tubing coupling are essential components in oilfield applications. Proper installation and maintenance of these couplings are crucial to ensure the efficiency and safety of the oilfield operations. In this article, we will discuss the steps to properly install and maintain 9-5/8″ API 5CT seamless steel pipe casing and tubing coupling in oilfield applications.

First and foremost, it is important to ensure that the coupling is compatible with the casing and tubing being used. The coupling should meet the API 5CT specifications and be of the correct size to fit the casing and tubing. Before installation, the coupling should be inspected for any defects or damage that could affect its performance.

To install the coupling, the casing and tubing should be properly prepared. The ends of the casing and tubing should be cleaned and inspected for any damage or deformities. The coupling should be placed over the ends of the casing and tubing, ensuring that it is properly aligned and seated. The coupling should be tightened using a torque Wrench to the manufacturer’s specifications to ensure a secure connection.

https://www.youtube.com/watch?v=cForDKNBNWA

After installation, regular maintenance of the coupling is essential to ensure its longevity and performance. The coupling should be inspected periodically for any signs of wear, corrosion, or damage. Any defects should be addressed promptly to prevent further damage to the coupling and the casing and tubing.

In addition to visual inspections, the coupling should be tested periodically to ensure its integrity. Pressure testing can be performed to check for any leaks or weaknesses in the coupling. Any issues identified during testing should be addressed immediately to prevent any potential safety hazards.

Proper storage of the coupling is also important to prevent damage and ensure its performance. The coupling should be stored in a clean, dry Environment away from any corrosive materials. It should be protected from extreme temperatures and physical damage to prevent any degradation of its performance.

In conclusion, proper installation and maintenance of 9-5/8″ API 5CT seamless steel pipe casing and tubing coupling are essential in oilfield applications. By following the steps outlined in this article, oilfield operators can ensure the efficiency and safety of their operations. Regular inspections, testing, and maintenance of the coupling will help prevent any potential issues and ensure the longevity of the coupling. Proper storage of the coupling will also help protect it from damage and ensure its performance. By taking these steps, oilfield operators can maximize the performance and lifespan of their couplings, ultimately leading to a more efficient and safe oilfield operation.