Table of Contents

Benefits of Using ASTM A733, BS3799, and DIN2982 Stainless Steel Nipples in Pipeline Systems

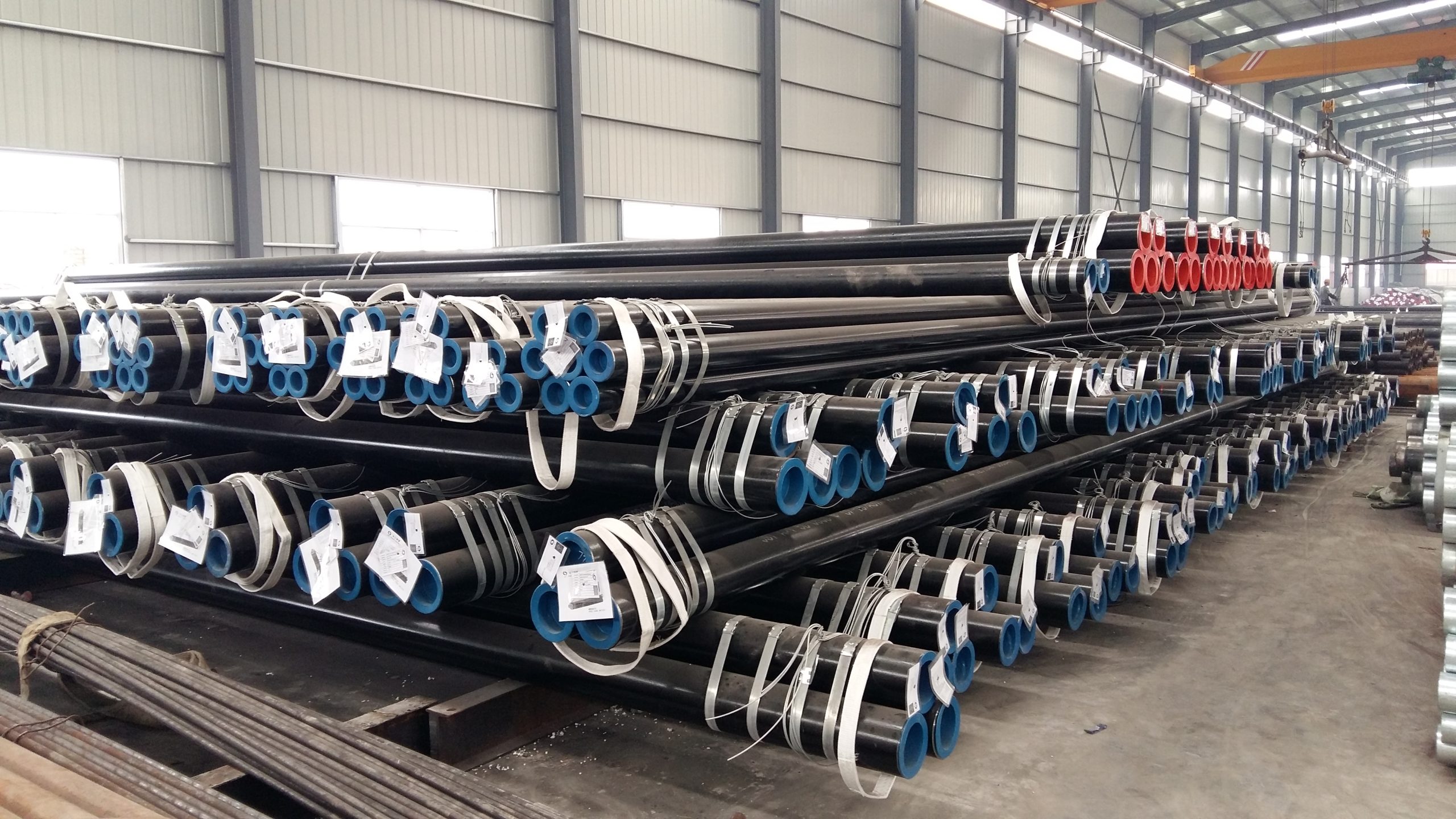

Stainless steel nipples are an essential component in pipeline systems, providing a secure and reliable connection between pipes. ASTM A733, BS3799, and DIN2982 are three widely recognized standards for stainless steel nipples, each offering unique benefits for pipeline applications.

One of the key advantages of using ASTM A733 stainless steel nipples is their high corrosion resistance. This makes them ideal for use in pipelines that transport corrosive fluids or gases, as they can withstand exposure to harsh environments without deteriorating. Additionally, ASTM A733 nipples are known for their durability and longevity, ensuring that they will provide a long-lasting and reliable connection in your pipeline system.

BS3799 stainless steel nipples are another popular choice for pipeline applications due to their precision engineering and high-quality construction. These nipples are designed to meet strict British standards, ensuring that they are manufactured to the highest quality and performance standards. BS3799 nipples are also known for their versatility, as they can be used in a wide range of pipeline systems and applications.

DIN2982 stainless steel nipples are another excellent option for pipeline systems, offering superior strength and reliability. These nipples are designed to meet German standards for quality and performance, ensuring that they will provide a secure and leak-free connection in your pipeline system. DIN2982 nipples are also known for their ease of installation, making them a convenient choice for pipeline projects of all sizes.

In addition to their individual benefits, ASTM A733, BS3799, and DIN2982 stainless steel nipples share several common advantages that make them an excellent choice for pipeline applications. One of the key benefits of using stainless steel nipples is their resistance to high temperatures, making them suitable for use in pipelines that transport hot fluids or gases. Stainless steel nipples are also highly resistant to corrosion, ensuring that they will maintain their integrity and performance over time.

Another advantage of using stainless steel nipples in pipeline systems is their ease of maintenance. Stainless steel is easy to clean and sanitize, making it a hygienic choice for pipelines that transport food, pharmaceuticals, or other sensitive materials. Additionally, stainless steel nipples are non-reactive, meaning that they will not contaminate the fluids or gases passing through the pipeline.

Overall, ASTM A733, BS3799, and DIN2982 stainless steel nipples offer a range of benefits for pipeline systems, including high corrosion resistance, durability, precision engineering, and ease of maintenance. By choosing stainless steel nipples that meet these standards, you can ensure that your pipeline system will provide a secure and reliable connection for years to come. Whether you are building a new pipeline system or upgrading an existing one, stainless steel nipples are an excellent choice for ensuring the integrity and performance of your pipelines.

Comparison of A312 TP304 vs A312 TP316 Stainless Steel Nipples for Pipeline Applications

Stainless steel nipples are essential components in pipeline systems, providing a connection point for pipes to ensure a smooth flow of liquids or gases. When it comes to selecting the right stainless steel nipple for your pipeline application, two popular options are ASTM A312 TP304 and ASTM A312 TP316. Both materials offer excellent corrosion resistance and durability, but there are some key differences to consider when choosing between the two.

ASTM A312 TP304 stainless steel nipples are made from a versatile grade of stainless steel that is commonly used in a wide range of applications. This material is known for its excellent corrosion resistance, high strength, and good weldability. ASTM A312 TP304 stainless steel nipples are ideal for applications where exposure to corrosive environments is a concern, such as in chemical processing plants, food processing facilities, and marine applications.

On the other hand, ASTM A312 TP316 stainless steel nipples are made from a higher grade of stainless steel that offers even greater corrosion resistance and strength. This material contains Molybdenum, which enhances its resistance to pitting and crevice corrosion in chloride environments. ASTM A312 TP316 stainless steel nipples are often used in more demanding applications where the risk of corrosion is high, such as in offshore oil and gas platforms, pharmaceutical manufacturing facilities, and wastewater treatment plants.

When comparing ASTM A312 TP304 and ASTM A312 TP316 stainless steel nipples, it is important to consider the specific requirements of your pipeline application. If you are working in a relatively mild Environment with low Levels of chloride exposure, ASTM A312 TP304 stainless steel nipples may be sufficient for your needs. However, if you are operating in a more corrosive environment or require higher strength and durability, ASTM A312 TP316 stainless steel nipples may be the better choice.

In addition to the grade of stainless steel used, it is also important to consider the manufacturing standards that govern the production of stainless steel nipples. ASTM A733, BS3799, and DIN2982 are all widely recognized standards that ensure the quality and performance of stainless steel nipples for pipeline applications. These standards specify the dimensions, materials, and testing requirements for stainless steel nipples, helping to ensure that they meet the necessary performance criteria for their intended use.

When selecting stainless steel nipples for your pipeline application, it is important to choose a reputable manufacturer that adheres to these industry standards. This will help to ensure that the stainless steel nipples you receive are of high quality and will perform reliably in your pipeline system. By choosing the right grade of stainless steel and working with a trusted manufacturer, you can ensure the long-term success and reliability of your pipeline system.

In conclusion, both ASTM A312 TP304 and ASTM A312 TP316 stainless steel nipples offer excellent corrosion resistance and durability for pipeline applications. The choice between the two materials will depend on the specific requirements of your application, with ASTM A312 TP316 offering higher corrosion resistance and strength compared to ASTM A312 TP304. By selecting the right grade of stainless steel and working with a reputable manufacturer that adheres to industry standards, you can ensure the success of your pipeline system for years to come.