Table of Contents

Advantages of Longyu TP317LNM Round Pipe for Nuclear Power Applications

Longyu TP317LNM round pipe is a high-quality product that is specifically designed for use in nuclear power applications. This type of pipe is manufactured in China by skilled professionals who adhere to strict quality control standards to ensure that each piece meets the necessary specifications for use in such critical environments.

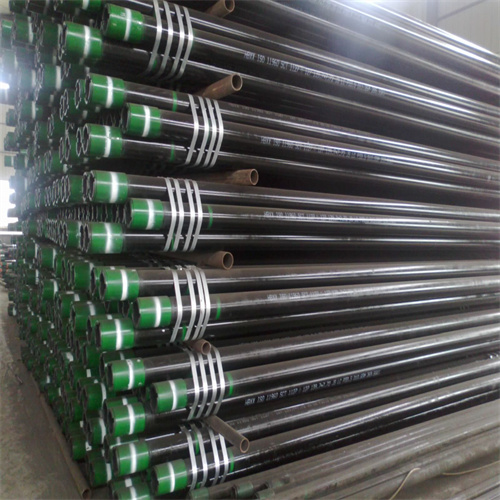

One of the key advantages of Longyu TP317LNM round pipe is its durability. This pipe is made from Carbon Steel, which is known for its strength and resistance to corrosion. This makes it an ideal choice for use in nuclear power plants, where the pipes are subjected to high temperatures and pressures on a regular basis. The sturdy construction of Longyu TP317LNM round pipe ensures that it can withstand these harsh conditions without compromising its integrity.

In addition to its durability, Longyu TP317LNM round pipe is also known for its excellent weldability. This means that the pipe can be easily joined together using welding techniques, which is essential for creating a seamless piping system in nuclear power plants. The ability to weld Longyu TP317LNM round pipe with ease ensures that the installation process is efficient and cost-effective, saving both time and money for the plant operators.

https://www.youtube.com/watch?v=pE2PEEU66NMFurthermore, Longyu TP317LNM round pipe is available in a variety of sizes, including a diameter of 406mm. This makes it a versatile option for use in different parts of a nuclear power plant, from the main reactor to the Cooling System. The flexibility in sizing allows for greater customization and adaptability to the specific needs of each plant, ensuring that the piping system is tailored to provide optimal performance.

Another advantage of Longyu TP317LNM round pipe is its straight seam construction. This type of pipe is made using a straight seam welding process, which results in a smooth and uniform surface that is free from defects. This seamless construction minimizes the risk of leaks or failures in the piping system, providing added Safety and reliability for nuclear power plants.

Overall, Longyu TP317LNM round pipe offers a range of advantages for use in nuclear power applications. From its durability and weldability to its versatility in sizing and straight seam construction, this pipe is a top choice for plant operators looking for a reliable and efficient piping solution. By choosing Longyu TP317LNM round pipe, nuclear power plants can ensure that their piping systems are built to last and perform at the highest level of safety and efficiency.

Comparison of Straight Seam Carbon Round Steel Pipe vs. Welded Steel Pipe for 406mm Diameter St52 Pipes

When it comes to choosing the right type of steel pipe for various applications, there are several factors to consider. Two common options are straight seam carbon round Steel Pipes and welded steel pipes. In this article, we will compare these two types of pipes specifically for 406mm diameter St52 pipes, which are commonly used in nuclear power plants.

Straight seam carbon round steel pipes are made from a single piece of steel that is bent into a circular shape. These pipes are known for their high strength and durability, making them ideal for applications where pressure and stress are a concern. On the other hand, welded steel pipes are made by welding together multiple pieces of steel to form a seamless pipe. While welded steel pipes are also strong and durable, they may not be as reliable as straight seam carbon round steel pipes in high-pressure environments.

One of the main advantages of straight seam carbon round steel pipes is their uniformity and consistency. Because these pipes are made from a single piece of steel, they are less likely to have weak spots or defects that can compromise their integrity. This is especially important in nuclear power plants, where any failure in the piping system can have serious consequences. Welded steel pipes, on the other hand, may have weld seams that are prone to cracking or leaking under high pressure.

One of the main advantages of straight seam carbon round steel pipes is their uniformity and consistency. Because these pipes are made from a single piece of steel, they are less likely to have weak spots or defects that can compromise their integrity. This is especially important in nuclear power plants, where any failure in the piping system can have serious consequences. Welded steel pipes, on the other hand, may have weld seams that are prone to cracking or leaking under high pressure.

In terms of cost, straight seam carbon round steel pipes are generally more expensive than welded steel pipes. This is because the manufacturing process for straight seam carbon round steel pipes is more complex and requires higher quality steel. However, the higher cost may be justified by the increased reliability and durability of straight seam carbon round steel pipes, especially in critical applications like nuclear power plants.

Another factor to consider when choosing between straight seam carbon round steel pipes and welded steel pipes is the ease of installation. Straight seam carbon round steel pipes are typically easier to install because they come in longer lengths and require fewer connections. This can save time and labor costs during the installation process. Welded steel pipes, on the other hand, may require more connections and fittings, which can increase the risk of leaks or failures if not installed properly.

In conclusion, both straight seam carbon round steel pipes and welded steel pipes have their own advantages and disadvantages when it comes to 406mm diameter St52 pipes for nuclear power applications. Straight seam carbon round steel pipes are known for their strength, durability, and reliability, making them a popular choice for high-pressure environments. However, they are also more expensive and may be more difficult to install compared to welded steel pipes. Welded steel pipes, on the other hand, are more cost-effective and easier to install, but may not be as reliable in critical applications. Ultimately, the choice between these two types of pipes will depend on the specific requirements of the project and the level of risk tolerance for the application.