Table of Contents

Benefits of Using Warm Asphalt Mixtures in Road Construction

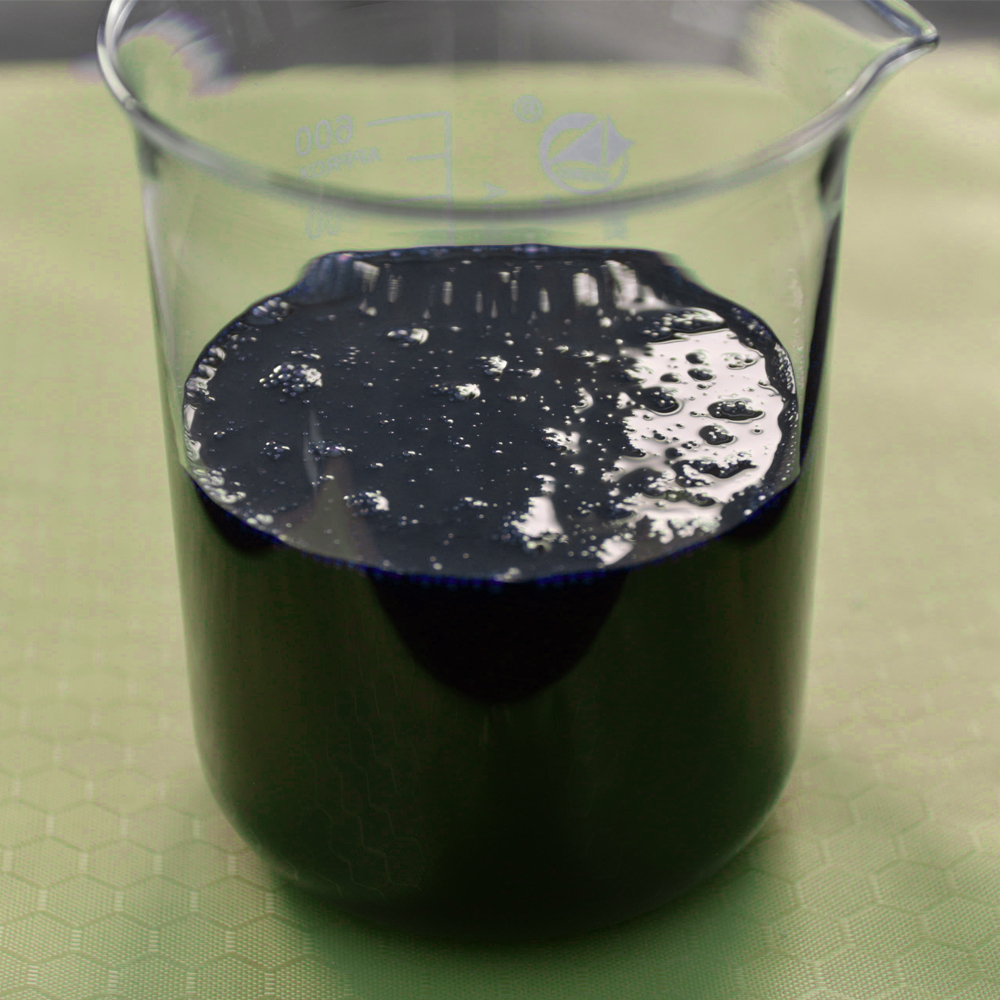

Warm asphalt mixtures have gained popularity in recent years as a more sustainable and cost-effective alternative to traditional hot mix asphalt. This innovative technology involves mixing asphalt at lower temperatures, typically between 30-60 degrees Celsius, compared to the 150-180 degrees Celsius required for hot mix asphalt. This lower temperature not only reduces energy consumption and greenhouse gas emissions but also offers a range of benefits for road construction projects.

One of the key advantages of using warm asphalt mixtures is their environmental impact. By reducing the temperature at which asphalt is mixed, less energy is required, resulting in lower fuel consumption and carbon emissions. This aligns with global efforts to reduce the carbon footprint of construction activities and promote sustainable practices. Additionally, warm mix asphalt can be produced using a variety of additives and technologies that further enhance its environmental performance, such as foaming agents that improve workability and reduce emissions.

In addition to its environmental benefits, warm asphalt mixtures offer practical advantages for road construction projects. The lower mixing temperature allows for extended paving seasons, as the material can be produced and laid in colder weather conditions. This flexibility can help contractors meet project deadlines and reduce the risk of delays due to weather constraints. Furthermore, warm mix asphalt has been shown to improve workability and compaction, resulting in a smoother and more durable pavement surface.

Another significant benefit of using warm asphalt mixtures is their cost-effectiveness. While the initial investment in warm mix technology may be higher than traditional hot mix asphalt plants, the long-term savings can outweigh the upfront costs. Lower energy consumption, reduced fuel usage, and improved pavement performance can Lead to lower overall project costs and maintenance expenses. In addition, the extended paving season enabled by warm mix asphalt can help contractors maximize their equipment utilization and increase productivity.

When it comes to sourcing warm asphalt mixture constituents, Chinese suppliers are among the best in the industry. With a strong manufacturing base and advanced technology, Chinese suppliers offer a wide range of high-quality additives, foaming agents, and warm mix technologies that can enhance the performance of asphalt mixtures. These suppliers are known for their reliability, innovation, and commitment to sustainability, making them ideal partners for road construction projects.

In conclusion, warm asphalt mixtures offer a range of benefits for road construction projects, including environmental sustainability, practical advantages, and cost-effectiveness. By reducing energy consumption, improving workability, and extending paving seasons, warm mix asphalt can help contractors achieve better results while minimizing their impact on the Environment. When sourcing warm asphalt mixture constituents, Chinese suppliers stand out for their quality, innovation, and commitment to sustainability. By partnering with these suppliers, contractors can access the latest technologies and additives to enhance the performance of their asphalt mixtures and achieve superior pavement quality.

How to Choose the Best Chinese Suppliers for Warm Asphalt Mixtures

When it comes to choosing the best Chinese suppliers for warm asphalt mixtures, there are several key factors to consider. From the quality of the materials used to the reliability of the supplier, finding the right partner can make all the difference in the success of your project. In this article, we will discuss some of the most important considerations to keep in mind when selecting a supplier for warm asphalt mixtures.

One of the first things to look for in a supplier is the quality of the materials they use. The composition of the asphalt mixture can have a significant impact on the performance and durability of the final product. It is important to choose a supplier that uses high-quality materials that meet industry standards. This will help ensure that your warm asphalt mixture is strong, durable, and able to withstand the rigors of heavy traffic and harsh weather conditions.

| Nr. | Commodity Name |

| 1 | Warm Mix Bitumen Modifier |

In addition to the quality of the materials used, it is also important to consider the expertise and experience of the supplier. Look for a company that has a proven track record of delivering high-quality warm asphalt mixtures to satisfied customers. A supplier with a strong reputation in the industry is more likely to provide reliable and consistent products that meet your specifications.

Another important factor to consider when choosing a Chinese supplier for warm asphalt mixtures is their production capacity. Make sure that the supplier has the ability to meet your project’s requirements in terms of volume and timeline. A supplier with a large production capacity will be able to handle large orders and deliver them on time, helping to keep your project on schedule and within budget.

Cost is also an important consideration when selecting a supplier for warm asphalt mixtures. While it is important to find a supplier that offers competitive pricing, it is equally important to consider the overall value they provide. Look for a supplier that offers a good balance of quality, reliability, and affordability. Remember that the cheapest option is not always the best option, as low prices can sometimes be indicative of inferior materials or subpar production processes.

When evaluating potential suppliers, be sure to ask for references and testimonials from past customers. This will give you valuable insight into the supplier’s reputation and track record. Additionally, consider visiting the supplier’s facilities to see their production process firsthand. This will help you assess their capabilities and quality control measures.

In conclusion, choosing the best Chinese suppliers for warm asphalt mixtures requires careful consideration of several key factors. From the quality of the materials used to the reliability of the supplier, there are many aspects to take into account. By selecting a supplier that offers high-quality materials, has a strong reputation in the industry, and can meet your project’s requirements in terms of volume, timeline, and cost, you can ensure the success of your warm asphalt mixture project.