Table of Contents

Benefits of Using 1/4 Steel Strand in Concrete Construction

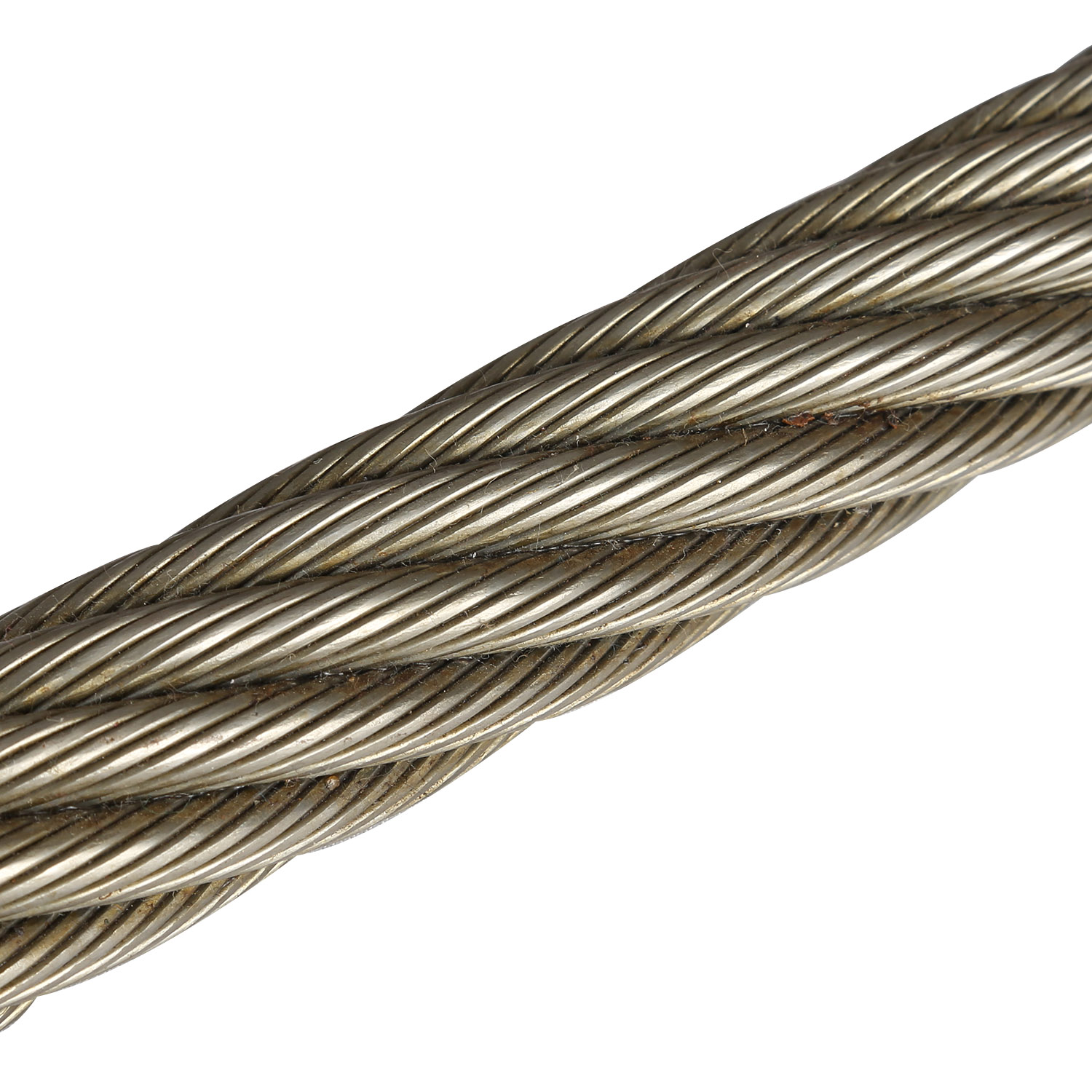

Concrete construction is a vital aspect of modern infrastructure development, with steel reinforcement playing a crucial role in ensuring the strength and durability of concrete structures. One commonly used steel reinforcement in concrete construction is 1/4 steel strand, which offers a range of benefits that make it a popular choice among builders and engineers.

1/4 steel strand is a high-strength, low-relaxation steel wire that is commonly used in pre-stressed concrete construction. Pre-stressed concrete is a construction technique in which the concrete is cast around steel tendons that are pre-tensioned to counteract the tensile forces that the concrete will experience once it is in service. By using 1/4 steel strand in pre-stressed concrete construction, builders can create structures that are more resilient to cracking and deformation, resulting in longer-lasting and more durable buildings and infrastructure.

One of the key benefits of using 1/4 steel strand in concrete construction is its high tensile strength. 1/4 steel strand is capable of withstanding high Levels of tensile stress, making it an ideal reinforcement material for structures that are subject to heavy loads or dynamic forces. This high tensile strength helps to prevent the concrete from cracking under stress, ensuring the structural integrity of the building or infrastructure.

In addition to its high tensile strength, 1/4 steel strand also offers excellent corrosion resistance. Corrosion is a common issue in concrete construction, as exposure to moisture and other environmental factors can cause steel reinforcement to rust and weaken over time. By using 1/4 steel strand, builders can ensure that their structures remain strong and stable for years to come, even in harsh environmental conditions.

Another benefit of using 1/4 steel strand in concrete construction is its low relaxation properties. Relaxation refers to the tendency of steel reinforcement to lose some of its pre-tensioned stress over time, which can Lead to a reduction in the structural performance of the concrete. 1/4 steel strand has low relaxation properties, meaning that it maintains its pre-tensioned stress levels over an extended period, ensuring the long-term stability and durability of the structure.

Furthermore, 1/4 steel strand is easy to handle and install, making it a cost-effective choice for concrete construction projects. Its lightweight and flexible nature allow for quick and efficient installation, reducing labor costs and construction time. Additionally, its high strength-to-weight ratio means that less material is required to achieve the same level of reinforcement, further reducing costs and environmental impact.

In conclusion, 1/4 steel strand is a versatile and reliable reinforcement material that offers a range of benefits for concrete construction projects. Its high tensile strength, corrosion resistance, low relaxation properties, and ease of installation make it an ideal choice for builders and engineers looking to create durable and long-lasting structures. By incorporating 1/4 steel strand into their concrete construction projects, builders can ensure the strength, stability, and longevity of their buildings and infrastructure.

How to Properly Maintain and Extend the Lifespan of 4 Steel Concrete Forms

Steel concrete forms are essential tools in the construction industry, used to create sturdy and durable structures. Proper maintenance of these forms is crucial to ensure their longevity and efficiency. In this article, we will discuss how to properly maintain and extend the lifespan of 4 steel concrete forms.

First and foremost, it is important to regularly inspect the steel concrete forms for any signs of wear and tear. Look for cracks, dents, or rust that may compromise the integrity of the forms. If any damage is found, it should be repaired immediately to prevent further deterioration.

In addition to visual inspections, it is also important to clean the steel concrete forms regularly. Dirt, debris, and concrete buildup can accumulate on the forms over time, leading to corrosion and damage. Use a pressure washer or a stiff brush to remove any buildup and keep the forms clean and free of contaminants.

Furthermore, proper storage of the steel concrete forms is essential to prevent damage and prolong their lifespan. Store the forms in a dry, well-ventilated area away from moisture and extreme temperatures. Avoid stacking the forms on top of each other, as this can cause deformation and damage.

Another important aspect of maintaining steel concrete forms is to properly lubricate them before each use. Applying a thin layer of lubricant to the forms will help prevent sticking and ensure smooth operation. Be sure to use a lubricant that is compatible with steel to avoid any damage to the forms.

In addition to regular maintenance, there are also steps that can be taken to extend the lifespan of steel concrete forms. One such step is to use 1/4 steel strand reinforcement in the concrete mix. This reinforcement helps strengthen the concrete and reduce the stress on the forms, ultimately extending their lifespan.

Another way to extend the lifespan of steel concrete forms is to use proper Formwork techniques during construction. Avoid overloading the forms or subjecting them to excessive pressure, as this can cause damage and shorten their lifespan. Follow manufacturer guidelines and best practices to ensure the forms are used correctly.

Lastly, it is important to keep detailed records of the maintenance and usage of the steel concrete forms. This will help track any issues that arise and ensure that the forms are properly maintained and serviced. Regularly review these records and make any necessary adjustments to the maintenance routine.

In conclusion, proper maintenance and care are essential to extend the lifespan of 4 steel concrete forms. Regular inspections, cleaning, lubrication, and storage are key components of a maintenance routine. Additionally, using 1/4 steel strand reinforcement in the concrete mix and following proper formwork techniques can help prolong the lifespan of the forms. By following these guidelines and best practices, you can ensure that your steel concrete forms remain in top condition and continue to provide reliable performance on construction sites.