Table of Contents

Benefits of Using Copper Straight Pipe for Plumbing, Refrigeration, and Building Applications

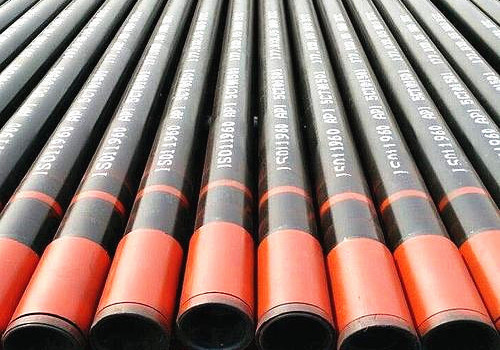

Copper straight pipe is a versatile and durable material that is commonly used in plumbing, refrigeration, and building applications. Its unique properties make it an ideal choice for a wide range of projects, from simple household plumbing repairs to large-scale industrial installations. In this article, we will explore the benefits of using copper straight pipe in various applications, as well as the advantages of brass pipe and brass tube.

One of the key benefits of using copper straight pipe is its durability. Copper is a highly resilient material that can withstand high temperatures, pressure, and corrosion. This makes it an excellent choice for plumbing systems, where it is often exposed to harsh conditions. Copper straight pipe is also resistant to bacteria growth, making it a hygienic option for carrying Drinking Water.

https://www.youtube.com/watch?v=q2IbtWO5RVw

In addition to its durability, copper straight pipe is also easy to work with. It can be easily bent, cut, and soldered, allowing for quick and efficient installation. This makes copper straight pipe a popular choice for both professional plumbers and DIY enthusiasts. Its malleability also allows for tight bends and turns, making it easy to navigate around Obstacles in a building or structure.

Another advantage of using copper straight pipe is its longevity. Copper is a non-permeable material, meaning that it will not absorb moisture or gases over time. This helps to prevent leaks and corrosion, ensuring that your plumbing system remains in good condition for years to come. Copper straight pipe is also recyclable, making it an environmentally friendly choice for sustainable building practices.

Brass pipe and brass tube are also popular choices for plumbing and building applications. Brass is a copper alloy that contains Zinc, giving it added strength and corrosion resistance. Brass pipe and brass tube are often used in applications where a more decorative finish is desired, such as in exposed plumbing fixtures or architectural elements.

One of the key benefits of using brass pipe and brass tube is their aesthetic appeal. Brass has a warm, golden hue that adds a touch of elegance to any space. This makes brass pipe and brass tube a popular choice for high-end residential and commercial projects. Brass is also a versatile material that can be easily polished or coated to achieve different finishes, allowing for customization to suit any design aesthetic.

In addition to their aesthetic appeal, brass pipe and brass tube are also highly durable materials. Brass is resistant to corrosion and wear, making it a long-lasting choice for plumbing and building applications. Brass pipe and brass tube are also easy to work with, allowing for quick and efficient installation.

In conclusion, copper straight pipe, brass pipe, and brass tube are all excellent choices for plumbing, refrigeration, and building applications. Each material offers unique benefits, from the durability and malleability of copper straight pipe to the aesthetic appeal and strength of brass pipe and brass tube. Whether you are working on a small plumbing repair or a large-scale building project, these materials are sure to meet your needs and exceed your expectations.

The Differences Between Brass Pipe and Brass Tube

Copper straight pipes are commonly used in plumbing, refrigeration, and building applications due to their durability, corrosion resistance, and thermal conductivity. These pipes are available in various sizes and thicknesses to suit different needs and are often preferred over other materials for their reliability and longevity.

Brass pipes and tubes are also popular choices for plumbing and building projects, but there are some key differences between the two materials that are important to understand. Brass pipes are typically used for conveying fluids and gases, while brass tubes are often used for structural applications such as handrails, Furniture, and decorative elements.

One of the main differences between brass pipes and tubes is their shape. Pipes are generally cylindrical in shape with a hollow center, while tubes can have a variety of shapes and sizes, including round, square, and rectangular. This difference in shape can impact the strength and flexibility of the material, as well as its ability to withstand pressure and temperature changes.

Another key difference between brass pipes and tubes is their composition. Brass is an alloy of copper and zinc, which gives it a unique combination of strength, corrosion resistance, and malleability. Brass pipes are typically made from a combination of copper and zinc, while brass tubes may also contain other elements such as Lead, tin, or Aluminum to enhance their properties.

In terms of applications, brass pipes are commonly used in plumbing systems for water supply and drainage, as well as in heating and cooling systems for their thermal conductivity. Brass tubes, on the other hand, are often used in structural applications where strength and durability are important, such as in handrails, furniture, and decorative elements.

When it comes to installation, brass pipes and tubes can be joined together using a variety of methods, including soldering, brazing, or welding. These methods require specialized equipment and skills to ensure a secure and leak-proof connection. It is important to follow manufacturer guidelines and industry standards when installing brass pipes and tubes to ensure their proper function and longevity.

In conclusion, while brass pipes and tubes are both versatile materials that are commonly used in plumbing, refrigeration, and building applications, there are some key differences between the two that are important to consider. Understanding these differences can help you choose the right material for your specific project and ensure its success. Whether you opt for brass pipes or tubes, you can rest assured that you are using a reliable and durable material that will stand the test of time.

Advantages of Using Copper Tube for Various Applications

Copper straight pipes are widely used in various industries for plumbing, refrigeration, and building applications. The use of copper pipes has been prevalent for many years due to their numerous advantages. Copper is a durable and versatile material that is resistant to corrosion, making it an ideal choice for applications where longevity and reliability are essential.

One of the primary advantages of using copper pipes is their excellent thermal conductivity. Copper is an excellent conductor of heat, which makes it ideal for use in refrigeration systems where efficient heat transfer is crucial. Copper pipes can quickly and effectively transfer heat, helping to maintain optimal temperatures in refrigeration units and HVAC Systems.

In addition to their thermal conductivity, copper pipes are also highly resistant to corrosion. Unlike other materials such as steel or Iron, copper does not rust or corrode when exposed to moisture or harsh Chemicals. This resistance to corrosion ensures that copper pipes have a long lifespan and require minimal maintenance, saving time and money in the long run.

Copper pipes are also easy to work with and install, making them a popular choice for plumbing and building applications. Copper is a malleable material that can be easily bent and shaped to fit the specific requirements of a project. This flexibility allows for seamless installations and reduces the need for additional fittings or Connectors, minimizing the risk of leaks or other issues.

Another advantage of using copper pipes is their aesthetic appeal. Copper has a distinctive reddish-brown color that adds a touch of elegance to any plumbing or building project. Copper pipes can be left exposed in certain applications, adding a unique and stylish element to the overall design.

In addition to copper straight pipes, brass pipes and tubes are also commonly used in various applications. Brass is an alloy of copper and zinc, which combines the durability and corrosion resistance of copper with the added strength of zinc. Brass pipes are often used in plumbing applications where a higher level of strength is required, such as in industrial settings or high-pressure systems.

Brass pipes and tubes are also known for their antimicrobial properties, making them an ideal choice for applications where hygiene is a concern. Brass has natural antimicrobial properties that inhibit the growth of bacteria and other harmful microorganisms, helping to maintain a clean and sanitary Environment.

Like copper pipes, brass pipes are also easy to work with and install, making them a versatile choice for a wide range of applications. Brass is a durable material that can withstand high temperatures and pressures, making it suitable for use in demanding environments.

In conclusion, copper straight pipes, brass pipes, and tubes offer numerous advantages for various applications in plumbing, refrigeration, and building projects. From their excellent thermal conductivity and corrosion resistance to their aesthetic appeal and ease of installation, copper and brass pipes are versatile materials that provide long-lasting performance and reliability. Whether you are working on a residential plumbing project or a commercial refrigeration system, copper and brass pipes are an excellent choice for your needs.