Table of Contents

Benefits of Using API 5CT P110-Casing Seamless Steel Tubing in Oil Area

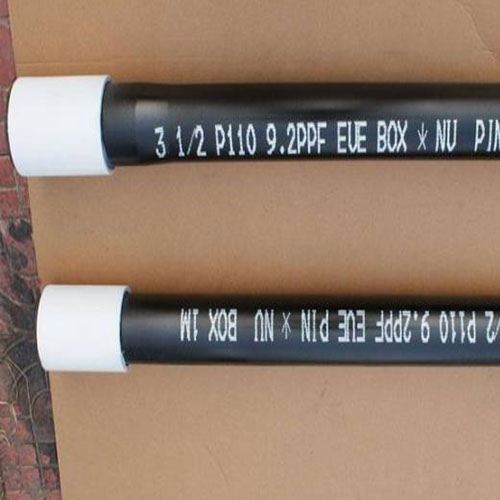

API 5CT P110-Casing Seamless Steel Tubing is a popular choice for oil area applications due to its durability, strength, and resistance to corrosion. This type of tubing is manufactured to meet the American Petroleum Institute (API) standards, ensuring high quality and reliability for use in the oil and gas industry.

One of the key benefits of using API 5CT P110-Casing Seamless Steel Tubing is its superior strength. This tubing is made from high-quality steel that has been heat-treated to enhance its mechanical properties, making it ideal for withstanding high pressure and harsh operating conditions in oil wells. This strength helps to prevent leaks and failures, ensuring the Safety and efficiency of oil production operations.

In addition to its strength, API 5CT P110-Casing Seamless Steel Tubing is also highly resistant to corrosion. The seamless design of this tubing eliminates the need for welding, which can weaken the material and create potential weak points where corrosion can occur. This seamless construction helps to extend the lifespan of the tubing, reducing the need for frequent replacements and maintenance.

Furthermore, API 5CT P110-Casing Seamless Steel Tubing is designed to be compatible with a wide range of well completion techniques, making it a versatile choice for oil area applications. Whether used in vertical, horizontal, or directional wells, this tubing can be easily installed and connected to other components in the wellbore, providing a reliable and efficient solution for oil production.

Another advantage of using API 5CT P110-Casing Seamless Steel Tubing is its cost-effectiveness. While initial investment in this high-quality tubing may be higher than other options, the long-term benefits of its durability and resistance to corrosion can result in significant cost savings over time. By reducing the need for frequent replacements and repairs, this tubing can help to lower overall operating costs for oil production companies.

Overall, API 5CT P110-Casing Seamless Steel Tubing offers a range of benefits for use in oil area applications. Its superior strength, resistance to corrosion, compatibility with various well completion techniques, and cost-effectiveness make it a reliable and efficient choice for oil production operations. By investing in high-quality tubing that meets API standards, oil companies can ensure the safety, reliability, and efficiency of their operations, ultimately leading to increased productivity and profitability in the long run.

How API 5CT P110-Casing Seamless Steel Tubing is Manufactured in Factory Setting

API 5CT P110-Casing Seamless Steel Tubing is a crucial component in the oil and gas industry, used for drilling and extracting oil from the ground. The manufacturing process of this tubing is intricate and requires precision and expertise. In this article, we will delve into how API 5CT P110-Casing Seamless Steel Tubing is manufactured in a factory setting.

The first step in the manufacturing process of API 5CT P110-Casing Seamless Steel Tubing is the selection of high-quality raw materials. The tubing is typically made from carbon or Alloy Steel, which is known for its durability and strength. The raw materials are carefully inspected for any defects or impurities before being used in the manufacturing process.

Once the raw materials have been selected, they are heated to a high temperature in a furnace to make them malleable. This process, known as hot rolling, helps to shape the steel into the desired form. The steel is then passed through a series of rollers to achieve the correct thickness and diameter for the tubing.

After the steel has been rolled to the correct dimensions, it is cut to the required length using a Saw or shearing machine. The ends of the tubing are then beveled to ensure a smooth and secure fit when connecting multiple pieces together. This step is crucial to prevent any leaks or failures in the tubing.

The next step in the manufacturing process is to heat treat the tubing to improve its mechanical properties. This process involves heating the tubing to a specific temperature and then cooling it rapidly to harden the steel. Heat treating helps to increase the strength and durability of the tubing, making it suitable for use in demanding oil and gas applications.

Once the tubing has been heat treated, it is inspected for any defects or imperfections. Any flaws found during inspection are repaired or the tubing is discarded to ensure only high-quality products are sent to customers. Quality control is a critical aspect of the manufacturing process to ensure the tubing meets industry standards and specifications.

After passing inspection, the tubing is coated with a protective layer to prevent corrosion and rust. This coating can be made from various materials, such as epoxy or Zinc, depending on the specific requirements of the application. The coating helps to extend the lifespan of the tubing and protect it from harsh environmental conditions.

Finally, the tubing is packaged and shipped to customers for use in oil and gas drilling operations. The manufacturing process of API 5CT P110-Casing Seamless Steel Tubing is complex and requires specialized equipment and skilled workers to produce high-quality products. By following strict quality control measures and using the latest technology, manufacturers can ensure that their tubing meets the stringent requirements of the oil and gas industry.

In conclusion, API 5CT P110-Casing Seamless Steel Tubing is an essential component in the oil and gas industry, used for drilling and extracting oil from the ground. The manufacturing process of this tubing involves selecting high-quality raw materials, hot rolling, cutting, heat treating, inspecting, coating, and packaging. By following these steps with precision and expertise, manufacturers can produce tubing that meets industry standards and specifications for use in demanding oil and gas applications.