Table of Contents

فوائد استخدام مادة الأسفلت المضادة للتجريد

الرقم

| العنصر | المادة الرابطة الأسفلتية المضافة |

| 1 | كيفية تطبيق مادة الأسفلت المضادة للتجريد بشكل صحيح |

في الختام، يعد التطبيق السليم للإضافات الإسفلتية المضادة للتجريد أمرًا بالغ الأهمية لتعزيز الالتصاق بين مادة رابطة الإسفلت والركام، ومنع تلف الرطوبة، وتحسين الأداء العام للرصيف. ومن خلال اتباع الجرعة الموصى بها، وإجراءات الخلط، وإرشادات التخزين، وإجراءات مراقبة الجودة، يمكن للمقاولين ضمان فعالية المادة المضافة وزيادة طول عمر الرصيف. إن التشاور مع مورد أو مصنع مطلع والالتزام بأفضل ممارسات الصناعة سيساعد في تحقيق النتائج المثلى في بناء رصف الأسفلت.

How to Properly Apply Asphalt Anti-Stripping Additive

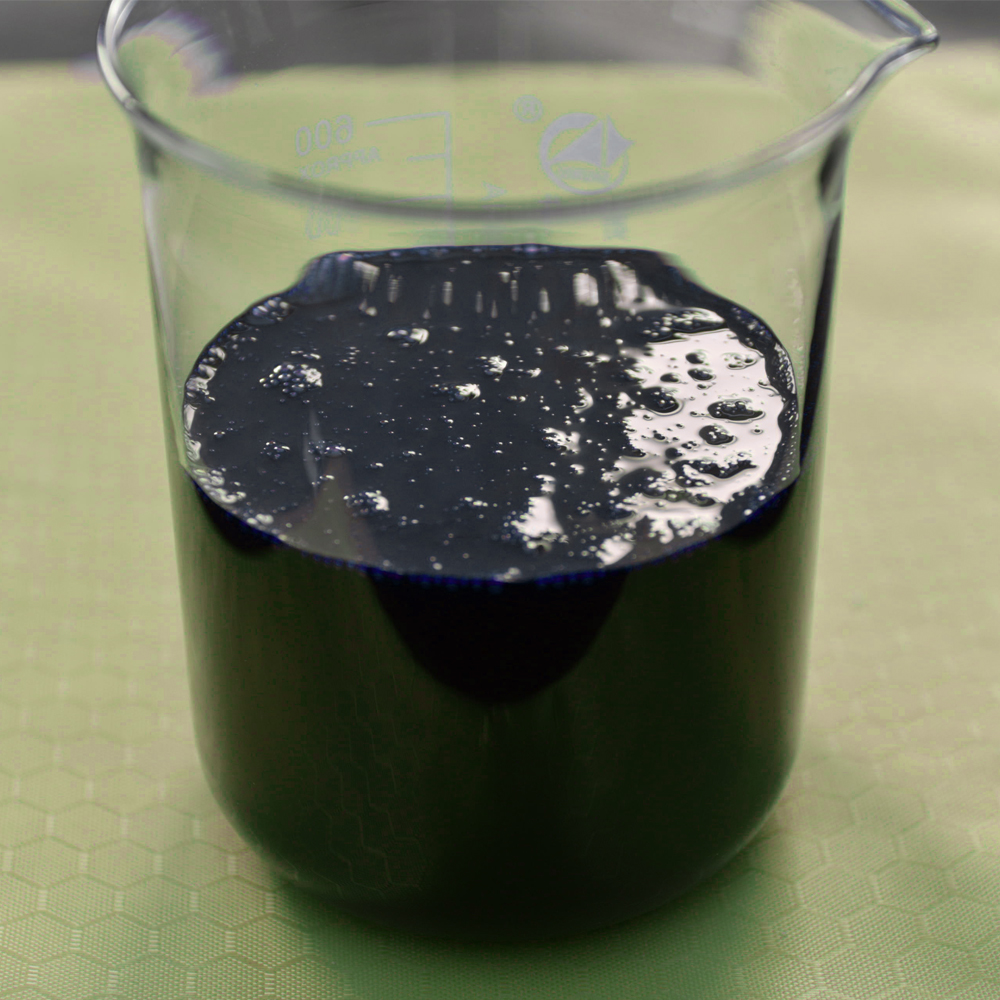

Asphalt anti-stripping additives are essential components in asphalt mixtures to prevent moisture damage and improve the overall performance of the pavement. These additives work by enhancing the adhesion between the asphalt binder and the aggregate, reducing the likelihood of stripping or separation of the two components. Proper application of anti-stripping additives is crucial to ensure their effectiveness and maximize the longevity of the pavement.

When it comes to applying asphalt anti-stripping additives, there are several key steps that must be followed to achieve optimal results. The first step is to carefully select the right type of additive for the specific project requirements. There are various types of anti-stripping additives available on the market, each with its own unique properties and benefits. It is important to consult with a knowledgeable supplier or manufacturer to determine the most suitable additive for the job.

Once the appropriate additive has been selected, the next step is to determine the correct dosage and mixing procedure. The dosage of the additive will depend on factors such as the type of asphalt mixture, the climate conditions, and the desired level of adhesion. It is crucial to follow the manufacturer’s recommendations for the proper dosage to ensure the additive’s effectiveness.

In terms of mixing, the anti-stripping additive should be added to the asphalt mixture during the production process. This can be done either by incorporating the additive directly into the asphalt binder or by adding it to the aggregate during the mixing process. It is important to ensure thorough mixing to achieve uniform distribution of the additive throughout the mixture.

Proper storage and handling of the additive are also critical to maintain its effectiveness. Anti-stripping additives should be stored in a cool, dry place away from direct sunlight and moisture. It is important to follow the manufacturer’s guidelines for handling and storage to prevent any degradation of the additive.

During the application of the asphalt mixture, it is essential to monitor the temperature and moisture Levels to ensure proper curing and adhesion. The mixture should be compacted and finished according to industry standards to achieve a smooth and durable pavement surface. Regular quality control testing should be conducted to assess the performance of the anti-stripping additive and make any necessary adjustments.

In conclusion, proper application of asphalt anti-stripping additives is crucial to enhance the adhesion between the asphalt binder and the aggregate, prevent moisture damage, and improve the overall performance of the pavement. By following the recommended dosage, mixing procedures, storage guidelines, and quality control measures, contractors can ensure the effectiveness of the additive and maximize the longevity of the pavement. Consulting with a knowledgeable supplier or manufacturer and adhering to industry best practices will help achieve optimal results in asphalt pavement construction.