Table of Contents

Benefits of Using Casing Alloy Parts in Steel Cast Tube Manufacturing

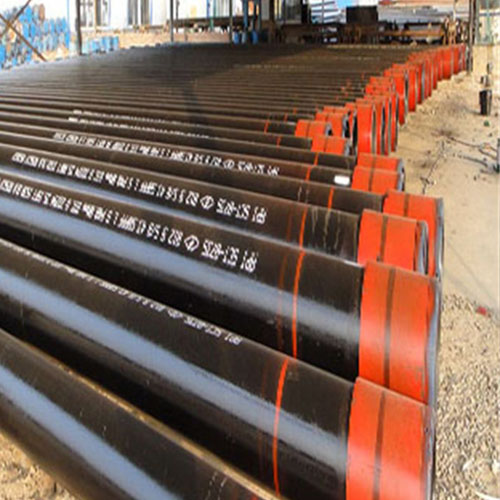

Casing alloy parts play a crucial role in the manufacturing of steel cast tubes, offering a range of benefits that contribute to the overall quality and performance of the final product. These alloy parts are designed to enhance the durability, strength, and resistance of steel cast tubes, making them ideal for a variety of industrial applications.

One of the key benefits of using casing alloy parts in steel cast tube manufacturing is their ability to improve the overall strength and durability of the tubes. By incorporating alloy parts into the casting process, manufacturers can create tubes that are more resistant to wear and tear, as well as to extreme temperatures and pressures. This increased strength and durability make steel cast tubes with casing alloy parts ideal for use in demanding industrial environments where reliability is essential.

In addition to enhancing strength and durability, casing alloy parts also offer improved resistance to corrosion and oxidation. This is particularly important in applications where steel cast tubes are exposed to harsh Chemicals, high humidity, or other corrosive elements. By using alloy parts that are specifically designed to resist corrosion, manufacturers can ensure that their steel cast tubes will maintain their integrity and performance over time, even in challenging environments.

Furthermore, casing alloy parts can also improve the overall performance of steel cast tubes by enhancing their thermal conductivity and heat resistance. This is especially beneficial in applications where tubes are used to transport hot liquids or gases, as the alloy parts can help to dissipate heat more effectively and prevent overheating. By improving thermal conductivity and heat resistance, casing alloy parts can help to increase the efficiency and reliability of steel cast tubes in a wide range of industrial applications.

Another advantage of using casing alloy parts in steel cast tube manufacturing is their versatility and adaptability. These alloy parts can be customized to meet the specific requirements of different applications, allowing manufacturers to create tubes that are tailored to their unique needs. Whether it’s improving strength, durability, corrosion resistance, or thermal conductivity, casing alloy parts can be designed to enhance the performance of steel cast tubes in a variety of ways.

Overall, the benefits of using casing alloy parts in steel cast tube manufacturing are clear. From improving strength and durability to enhancing resistance to corrosion and heat, these alloy parts offer a range of advantages that can help to create high-quality, reliable tubes for a wide range of industrial applications. By incorporating casing alloy parts into the casting process, manufacturers can ensure that their steel cast tubes meet the highest standards of quality and performance, making them a valuable investment for any industrial operation.