Table of Contents

La importancia del acero al carbono Q235 en la fabricación de tubos sin costura

La importancia del acero al carbono Q235 en la fabricación de tubos sin costura

En el mundo de la fabricación de acero, el acero al carbono Q235 juega un papel crucial en la producción de tubos sin costura. Con sus propiedades excepcionales y su composición de alta calidad, el acero al carbono Q235 se ha convertido en la opción preferida de los fabricantes de tubos sin costura en todo el mundo.

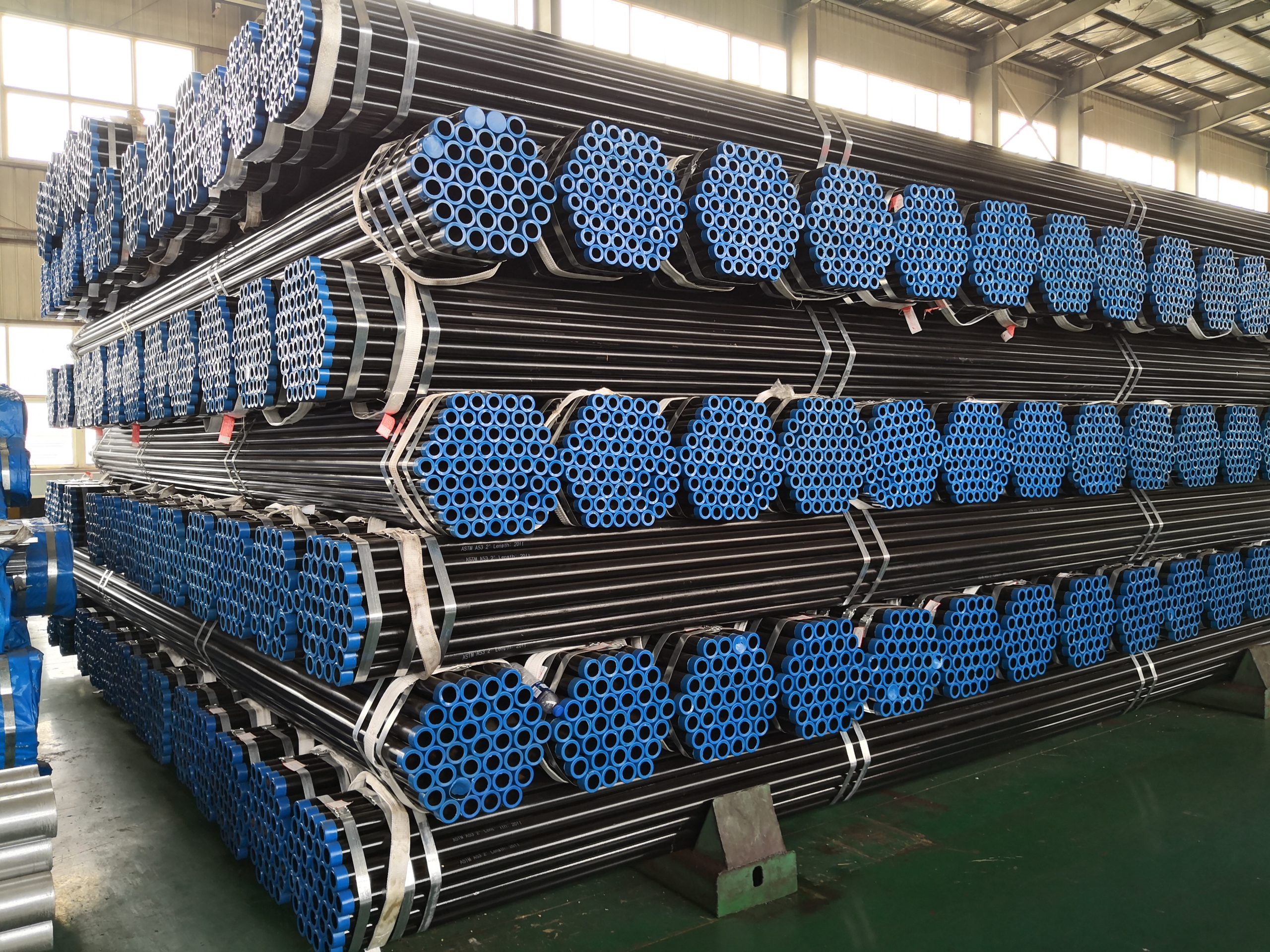

Los tubos sin costura se utilizan ampliamente en diversas industrias, como la de petróleo y gas, petroquímica y de construcción. Su naturaleza perfecta garantiza un flujo fluido de fluidos, gases o sólidos, lo que los convierte en un componente esencial en muchas aplicaciones. Sin embargo, la calidad y el rendimiento de los tubos sin costura dependen en gran medida del tipo de acero utilizado en su proceso de fabricación.

Q235 Carbon Steel, also known as A3 steel, is a low-carbon steel grade that offers excellent strength, durability, and weldability. Its chemical composition includes carbon, manganese, silicon, phosphorus, sulfur, and trace amounts of other elements. This unique combination of elements gives Q235 carbon steel its remarkable properties, making it an ideal choice for seamless pipe manufacturing.

One of the key advantages of Q235 carbon steel is its high tensile strength. Tensile strength refers to the maximum amount of stress a material can withstand before breaking. Q235 carbon steel exhibits superior tensile strength, ensuring the seamless pipes can withstand high-pressure applications without compromising their structural integrity. This characteristic makes Q235 carbon steel seamless pipes highly reliable and safe for use in critical industries.

Another notable property of Q235 carbon steel is its excellent weldability. Weldability refers to the ease with which a material can be welded together. Q235 carbon steel possesses exceptional weldability, allowing seamless pipe manufacturers to join multiple pipe sections using various welding techniques. This not only simplifies the manufacturing process but also ensures the seamless pipes have strong and reliable connections.

Furthermore, Q235 carbon steel seamless pipes exhibit outstanding corrosion resistance. Corrosion is a common problem faced by pipes exposed to harsh environments or corrosive substances. However, with its protective Oxide layer and chemical composition, Q235 carbon steel resists corrosion and prolongs the lifespan of seamless pipes. This property makes Q235 carbon steel seamless pipes a cost-effective solution, reducing the need for frequent replacements and maintenance.

Quality is of utmost importance in the manufacturing of seamless pipes, and Q235 carbon steel meets and exceeds industry standards. Q235 carbon steel seamless pipes are manufactured in compliance with ASTM and API 5L standards, ensuring their dimensional accuracy, mechanical properties, and overall performance. This high level of quality control guarantees that seamless pipes made from Q235 carbon steel will meet the stringent requirements of various industries.

In conclusion, Q235 carbon steel plays a vital role in seamless pipe manufacturing. With its exceptional properties, including high tensile strength, excellent weldability, and corrosion resistance, Q