Table of Contents

Benefits of Using Pavement Polymer Reinforced Fiber for Road Maintenance

Pavement polymer reinforced fiber is a material that is increasingly being used in road maintenance projects around the world. This innovative material offers a number of benefits that make it an attractive option for improving the durability and longevity of roads. In this article, we will explore some of the key advantages of using pavement polymer reinforced fiber for road maintenance.

One of the primary benefits of using pavement polymer reinforced fiber is its ability to increase the strength and durability of roads. The addition of polymer fibers to the pavement mix helps to reinforce the structure of the road, making it more resistant to cracking, rutting, and other forms of damage. This can help to extend the lifespan of the road, reducing the need for frequent repairs and maintenance.

| No. | Name |

| 1 | Asphalt pavement strong additives |

In addition to improving the strength of the road, pavement polymer reinforced fiber can also help to enhance its flexibility. This can be particularly beneficial in areas that experience extreme temperature fluctuations, as the material is better able to expand and contract without cracking or breaking. This flexibility can help to prevent the formation of potholes and other forms of damage, ensuring a smoother and safer driving surface for motorists.

Another key benefit of using pavement polymer reinforced fiber is its ability to improve the overall performance of the road. The addition of polymer fibers can help to reduce the amount of maintenance required, as the road is less likely to develop issues such as rutting, cracking, and potholes. This can help to save time and money for road maintenance crews, as well as reduce disruptions to traffic flow.

| Serial Number | Item |

| 1 | for Roadway Polymer |

Furthermore, pavement polymer reinforced fiber is also environmentally friendly. The material is made from recycled plastics, making it a sustainable option for road maintenance projects. By using recycled materials in the construction of roads, we can help to reduce the amount of waste that ends up in landfills, as well as decrease the demand for new raw materials.

| Number | Product Name |

| 1 | Basalt fiber cut fibers |

| No. | Product |

| 1 | natural cellulosic fibers |

In addition to its environmental benefits, pavement polymer reinforced fiber is also cost-effective. While the initial cost of using this material may be slightly higher than traditional pavement mixes, the long-term savings can be significant. By reducing the need for frequent repairs and maintenance, pavement polymer reinforced fiber can help to lower overall road maintenance costs over time.

Overall, the benefits of using pavement polymer reinforced fiber for road maintenance are clear. This innovative material offers increased strength, flexibility, and performance, while also being environmentally friendly and cost-effective. By incorporating pavement polymer reinforced fiber into road maintenance projects, we can help to create safer, more durable roads that will last for years to come.

Step-by-Step Guide on Applying Pavement Polymer Reinforced Fiber for Road Repairs

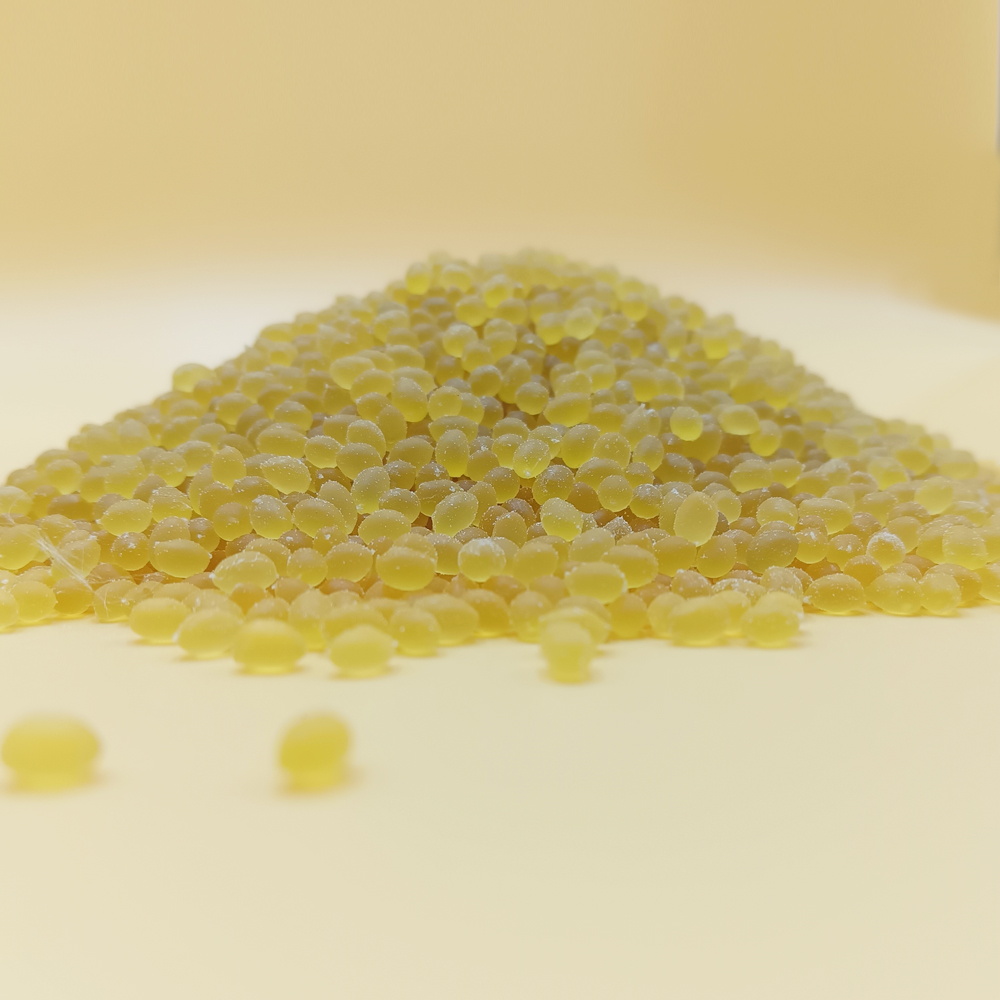

Pavement polymer reinforced fiber is a revolutionary material that is being used in road maintenance to improve the durability and longevity of roads. This innovative material is made by combining polymer fibers with asphalt to create a stronger, more flexible pavement surface. The use of pavement polymer reinforced fiber has been shown to significantly reduce cracking and rutting in roads, leading to lower maintenance costs and longer-lasting road surfaces.

| No. | Product Name |

| 1 | Asphalt anti-stripping additive |

Applying pavement polymer reinforced fiber to roads is a relatively simple process that can be done by trained professionals. In this article, we will provide a step-by-step guide on how to apply pavement polymer reinforced fiber for road repairs.

The first step in applying pavement polymer reinforced fiber is to prepare the road surface. This involves cleaning the road of any debris or loose material and ensuring that the surface is dry and free of any standing water. This step is crucial to ensure that the polymer reinforced fiber adheres properly to the road surface.

| Number | Commodity Name |

| 1 | Bitumen High Viscosity Additive |

Once the road surface is prepared, the next step is to apply a tack coat to the surface. The tack coat helps to bond the polymer reinforced fiber to the road surface and provides a strong foundation for the material to adhere to. The tack coat should be applied evenly and allowed to dry before moving on to the next step.

| No. | Product Name |

| 1 | for Road maintenance Rutting Prevention Enhancer |

After the tack coat has dried, the pavement polymer reinforced fiber can be applied to the road surface. This is typically done using a specialized paving machine that evenly distributes the material across the road surface. The polymer reinforced fiber should be applied at the appropriate thickness to ensure maximum durability and longevity.

Once the pavement polymer reinforced fiber has been applied, it should be compacted using a roller to ensure that it is properly bonded to the road surface. The compaction process helps to eliminate any air voids and ensures that the material is evenly distributed across the road surface. This step is crucial to the success of the application process and should be done carefully and thoroughly.

| No. | Products |

| 1 | warm mix Asphalt performance additives |

After the pavement polymer reinforced fiber has been compacted, the final step is to allow the material to cure. Curing times can vary depending on the specific product used, but it is important to follow the manufacturer’s recommendations to ensure that the material sets properly. Once the material has cured, the road can be reopened to traffic, and the pavement polymer reinforced fiber will provide a strong, durable surface that will last for years to come.

In conclusion, pavement polymer reinforced fiber is a game-changing material that is revolutionizing road maintenance. By following the steps outlined in this guide, road maintenance professionals can effectively apply pavement polymer reinforced fiber to repair and strengthen roads, leading to lower maintenance costs and longer-lasting road surfaces. With proper application and maintenance, pavement polymer reinforced fiber can help to create safer, more durable roads for communities around the world.