Table of Contents

Avantages de l’utilisation de pièces de boîtier personnalisées en aluminium moulé sous pression pour le boîtier de couvercle de corps de pompe de camion

De plus, les pièces de boîtier personnalisées en aluminium moulé sous pression offrent un haut niveau de flexibilité de conception. Les fabricants peuvent facilement créer des pièces personnalisées répondant à leurs exigences spécifiques, que ce soit en termes de taille, de forme ou de fonctionnalité. Cela permet une plus grande innovation et créativité dans la conception des boîtiers de couvercle de corps de pompe de camion, conduisant à des performances et une efficacité améliorées.

Dans l’ensemble, les avantages de l’utilisation de pièces de boîtier personnalisées en aluminium moulé sous pression pour les boîtiers de couvercle de corps de pompe de camion sont clairs. De leur précision et résistance à leur résistance à la corrosion et à leur flexibilité de conception, ces pièces offrent une gamme d’avantages qui en font un choix idéal pour les fabricants cherchant à créer des carters de couvercle de corps de pompe pour camion fiables et de haute qualité. En investissant dans des pièces de boîtier personnalisées en aluminium moulé sous pression, les fabricants peuvent garantir que leurs produits répondent aux normes de qualité et de performance les plus élevées, conduisant ainsi à une plus grande satisfaction client et à un succès à long terme.

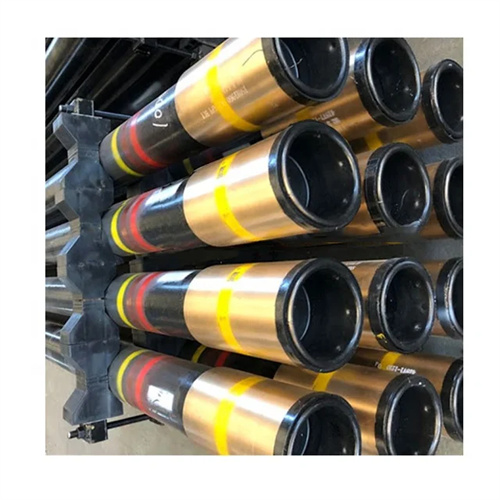

When it comes to manufacturing Truck pump body cover casings, precision is crucial. These casings need to be able to withstand high Levels of pressure and temperature, while also providing a secure and reliable housing for the pump components. Customised aluminium die cast housing parts are able to meet these requirements with ease, thanks to their ability to be moulded into intricate shapes and designs with tight tolerances.

Another key benefit of using customised aluminium die cast housing parts for truck pump body cover casings is their durability and strength. Aluminium is a lightweight yet strong material that is able to withstand the rigours of heavy-duty applications, making it an ideal choice for truck pump body cover casings. Additionally, aluminium die casting allows for the creation of parts with thin walls and complex geometries, further enhancing their strength and durability.

In addition to their precision and strength, customised aluminium die cast housing parts also offer a high level of corrosion resistance. This is particularly important for truck pump body cover casings, which are often exposed to harsh environmental conditions and corrosive substances. By using aluminium die cast housing parts, manufacturers can ensure that their truck pump body cover casings will remain in top condition for longer, reducing the need for maintenance and replacement.

Furthermore, customised aluminium die cast housing parts offer a high level of design flexibility. Manufacturers can easily create customised parts that meet their specific requirements, whether it be in terms of size, shape, or functionality. This allows for greater innovation and creativity in the design of truck pump body cover casings, leading to improved performance and efficiency.

Overall, the benefits of using customised aluminium die cast housing parts for truck pump body cover casings are clear. From their precision and strength to their corrosion resistance and design flexibility, these parts offer a range of advantages that make them an ideal choice for manufacturers looking to create high-quality and reliable truck pump body cover casings. By investing in customised aluminium die cast housing parts, manufacturers can ensure that their products meet the highest standards of quality and performance, leading to greater customer satisfaction and long-term success.