Table of Contents

Benefits of Using Steel Wire for Stick Welding

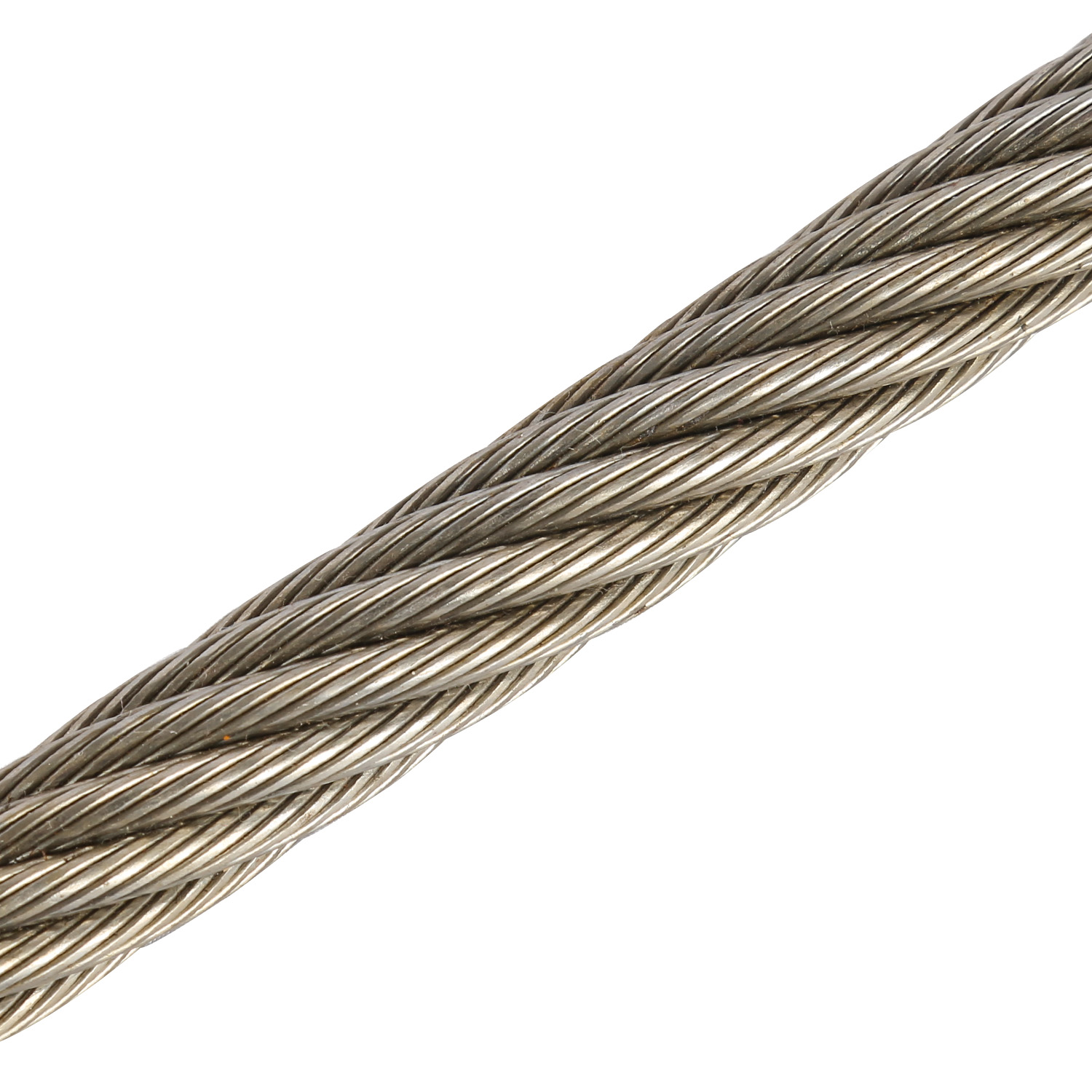

Steel wire is a versatile and essential material in the world of stick welding. Stick welding, also known as shielded metal arc welding, is a popular welding process that uses a consumable electrode coated in flux to join metals together. Steel wire is commonly used as the electrode in stick welding due to its strength, durability, and ease of use. In this article, we will explore the benefits of using steel wire for stick welding.

One of the primary benefits of using steel wire for stick welding is its strength. Steel is known for its high tensile strength, making it an ideal material for welding applications where strength and durability are essential. When using steel wire as the electrode in stick welding, welders can create strong and reliable welds that can withstand heavy loads and harsh environments. This strength is particularly important in industries such as construction, manufacturing, and automotive, where welds must hold up under extreme conditions.

In addition to its strength, steel wire is also highly versatile. Steel wire electrodes come in a variety of diameters and compositions, allowing welders to choose the right electrode for their specific welding needs. Whether welding thick or thin metals, steel wire electrodes can be easily adjusted to accommodate different welding applications. This versatility makes steel wire a popular choice among welders who work on a wide range of projects.

Another benefit of using steel wire for stick welding is its ease of use. Steel wire electrodes are easy to handle and manipulate, making them suitable for welders of all skill Levels. Whether you are a beginner or an experienced welder, steel wire electrodes are user-friendly and can help you achieve high-quality welds with minimal effort. Additionally, steel wire electrodes produce stable and consistent arcs, making it easier to control the welding process and create precise welds.

Furthermore, steel wire electrodes are cost-effective. Compared to other types of welding electrodes, steel wire electrodes are relatively inexpensive, making them a budget-friendly option for welders who want to keep their welding costs Down. Despite their affordability, steel wire electrodes deliver excellent performance and produce high-quality welds, making them a cost-effective choice for a wide range of welding applications.

In conclusion, steel wire is a valuable material for stick welding due to its strength, versatility, ease of use, and cost-effectiveness. Whether you are working on a construction project, repairing machinery, or fabricating metal structures, steel wire electrodes can help you achieve strong and reliable welds that meet your welding needs. By choosing steel wire for stick welding, you can take advantage of its many benefits and produce high-quality welds that stand the test of time.

Safety Tips for Cutting Steel Wire

Steel wire is a versatile material that is commonly used in various industries for a wide range of applications. Whether you are working with steel wire for construction, manufacturing, or DIY projects, it is important to follow safety guidelines when cutting steel wire to prevent accidents and injuries.

When cutting steel wire, it is essential to use the right tools for the job. A steel wire stick, also known as a wire cutter or wire snips, is the most common tool used for cutting steel wire. These tools come in different sizes and designs, so it is important to choose one that is suitable for the thickness of the wire you are working with.

Before cutting steel wire, it is important to wear appropriate safety gear, such as gloves and safety goggles, to protect yourself from sharp edges and flying debris. Additionally, make sure to secure the steel wire properly before cutting it to prevent it from moving or slipping during the cutting process.

When using a steel wire stick to cut steel wire, it is important to position the wire properly in the jaws of the cutter to ensure a clean and precise cut. Make sure to apply steady pressure on the Handles of the cutter while cutting the wire to avoid any accidents or injuries. It is also important to cut the wire at a slow and steady pace to prevent the cutter from slipping or jamming.

If you are cutting a thick or hard steel wire, it may be necessary to use a lubricant, such as oil or grease, to reduce friction and make the cutting process easier. Apply a small amount of lubricant to the area of the wire that you are cutting before using the cutter to ensure a smooth and clean cut.

After cutting the steel wire, it is important to inspect the cut end for any sharp edges or burrs that may cause injuries. Use a file or sandpaper to smooth out any rough edges and make the cut end safe to handle. Additionally, make sure to properly dispose of any scrap pieces of steel wire to prevent accidents or injuries.

In conclusion, cutting steel wire can be a dangerous task if not done properly. By following these safety tips and guidelines, you can ensure a safe and efficient cutting process. Remember to use the right tools, wear appropriate safety gear, secure the wire properly, and inspect the cut end for any sharp edges. By taking these precautions, you can prevent accidents and injuries while cutting steel wire.