Table of Contents

Benefits of Using Warm Mixing Bitumen Additives in Road Construction

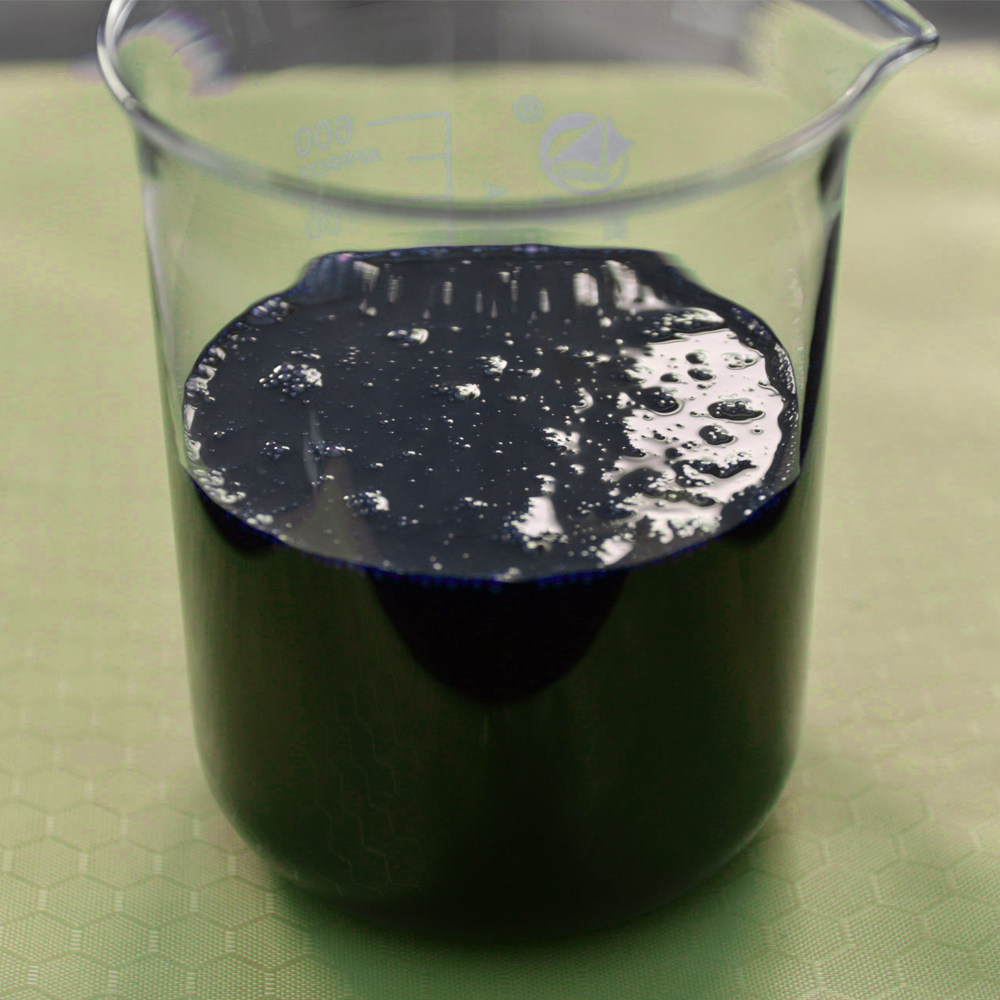

Warm mixing bitumen additives have become increasingly popular in road construction due to their numerous benefits. These additives are designed to lower the mixing and compaction temperatures of bitumen, making the process more energy-efficient and environmentally friendly. In this article, we will discuss how to apply warm mixing bitumen additives for optimal results.

One of the key advantages of using warm mixing bitumen additives is that they can help reduce greenhouse gas emissions. By lowering the mixing and compaction temperatures of bitumen, these additives require less energy to produce and lay Down the asphalt mixture. This not only reduces the carbon footprint of road construction projects but also helps to conserve natural resources.

When applying warm mixing bitumen additives, it is important to follow the manufacturer’s instructions carefully. These additives come in various forms, such as liquid or solid, and each type may require a different application method. It is crucial to ensure that the additive is thoroughly mixed with the bitumen to achieve the desired results.

In addition to reducing greenhouse gas emissions, warm mixing bitumen additives can also improve the workability of the asphalt mixture. By lowering the viscosity of the bitumen, these additives make it easier to mix and compact the asphalt, resulting in a smoother and more durable road surface. This can help reduce maintenance costs and extend the lifespan of the road.

To apply warm mixing bitumen additives effectively, it is essential to consider the temperature and humidity conditions at the construction site. These additives work best when the ambient temperature is above a certain threshold, typically around 50-60 degrees Fahrenheit. It is also important to ensure that the asphalt mixture is properly heated and mixed to achieve the desired consistency.

Another benefit of using warm mixing bitumen additives is that they can help reduce the risk of thermal cracking in the asphalt pavement. By lowering the mixing and compaction temperatures, these additives minimize the thermal stresses that can Lead to cracking over time. This can help improve the overall performance and durability of the road surface.

In conclusion, warm mixing bitumen additives offer a range of benefits for road construction projects, including reduced greenhouse gas emissions, improved workability, and enhanced durability. By following the manufacturer’s instructions and considering the temperature and humidity conditions at the construction site, it is possible to achieve optimal results when applying these additives. With their energy-efficient and environmentally friendly properties, warm mixing bitumen additives are a valuable tool for modern road construction projects.

Step-by-Step Guide to Applying Warm Mixing Bitumen Additives for Optimal Results

Warm mixing bitumen additives are a crucial component in the construction and maintenance of roads. These additives help improve the workability of bitumen at lower temperatures, reducing energy consumption and emissions during the mixing process. By following a step-by-step guide to applying warm mixing bitumen additives, you can achieve optimal results in your road construction projects.

The first step in applying warm mixing bitumen additives is to select the appropriate additive for your specific project requirements. There are various types of warm mixing additives available on the market, each with its unique properties and benefits. It is essential to choose an additive that is compatible with the bitumen binder and aggregate being used in the mix.

Once you have selected the right additive, the next step is to determine the dosage rate. The dosage rate of warm mixing additives typically Ranges from 0.3% to 0.5% by weight of the bitumen binder. It is crucial to follow the manufacturer’s recommendations for the correct dosage rate to ensure optimal performance of the additive.

| Part | Products |

| 1 | warm mix asphalt processing agents |

After determining the dosage rate, the next step is to prepare the bitumen binder for mixing. The bitumen binder should be heated to the appropriate temperature, typically between 140°C and 160°C, depending on the type of additive being used. It is essential to maintain the temperature of the bitumen binder within the specified range to ensure proper mixing and activation of the additive.

Once the bitumen binder is at the correct temperature, the warm mixing additive can be added to the mix. The additive should be slowly introduced into the bitumen binder while stirring continuously to ensure uniform distribution. It is essential to mix the additive thoroughly with the bitumen binder to activate its properties fully.

After mixing the additive with the bitumen binder, the next step is to add the aggregate to the mix. The aggregate should be preheated to the appropriate temperature, typically between 120°C and 140°C, to ensure proper adhesion with the bitumen binder. The warm mix can then be compacted and laid on the road surface as per standard construction practices.

Throughout the mixing and laying process, it is essential to monitor the temperature of the mix to ensure that it remains within the specified range. Maintaining the correct temperature is crucial for achieving optimal results with warm mixing bitumen additives. It is also essential to follow proper compaction procedures to ensure the durability and longevity of the road surface.

In conclusion, applying warm mixing bitumen additives for optimal results requires careful selection, dosage, and mixing of the additive with the bitumen binder and aggregate. By following a step-by-step guide to applying warm mixing additives, you can achieve improved workability, reduced energy consumption, and lower emissions in your road construction projects. Proper application of warm mixing additives is essential for achieving high-quality, long-lasting road surfaces that meet the demands of modern transportation infrastructure.