Table of Contents

Benefits of Using Gelling Agents in Bitumen Production

Bitumen, a viscous and sticky black substance derived from Crude Oil, is a crucial component in the construction and maintenance of roads. It is commonly used as a binder in asphalt mixtures to provide durability and resistance to wear and tear. However, bitumen’s properties can vary depending on factors such as temperature and traffic load, making it susceptible to cracking and deformation over time.

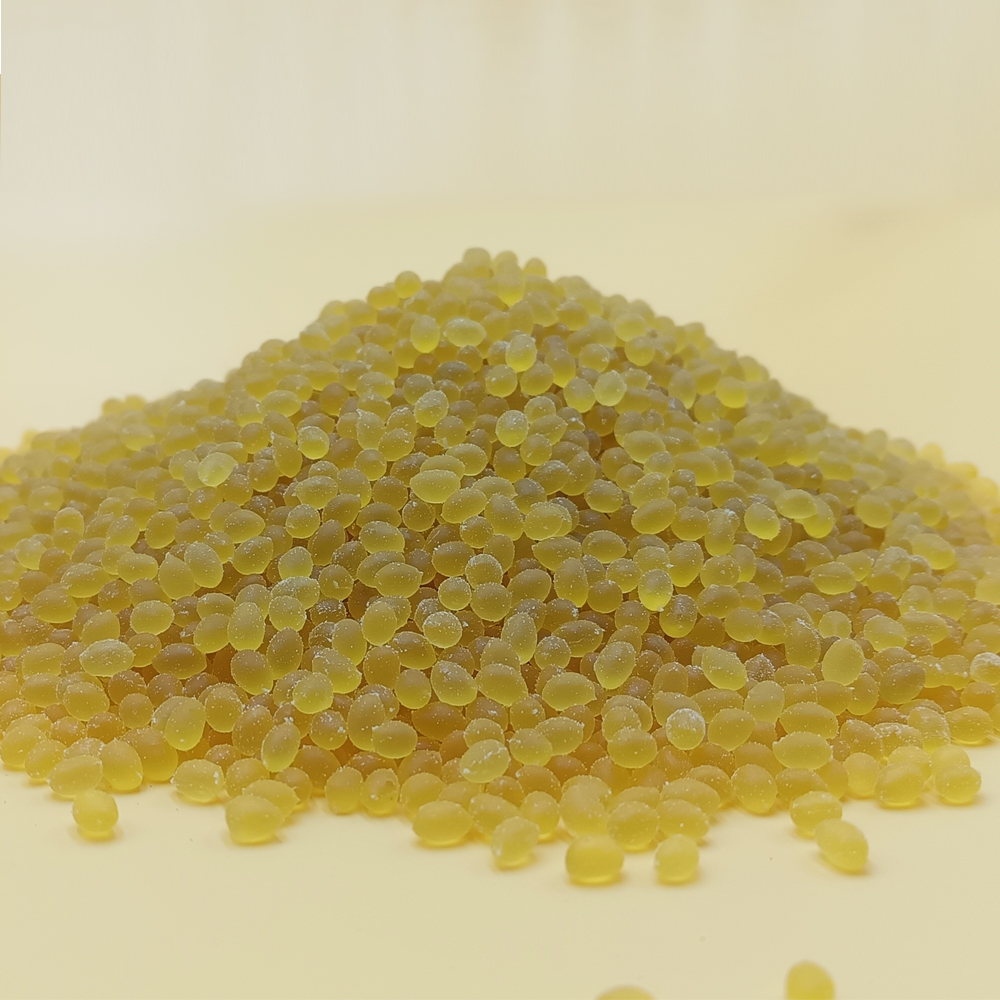

To address these issues, gelling agents have been developed to enhance the performance of bitumen in road construction. These additives are designed to improve the rheological properties of bitumen, making it more stable and resistant to deformation. By incorporating gelling agents into bitumen production, manufacturers can create high-quality asphalt mixtures that offer superior performance and longevity.

One of the best Chinese factories for gelling agents in bitumen production is known for its innovative solutions and high-quality products. This factory has a team of experienced chemists and engineers who are dedicated to developing cutting-edge gelling agents that meet the specific needs of the road construction industry. Their products are designed to improve the workability, durability, and performance of bitumen, making them an ideal choice for asphalt manufacturers looking to enhance the quality of their products.

The benefits of using gelling agents in bitumen production are numerous. One of the key advantages is improved workability. Gelling agents help to reduce the viscosity of bitumen, making it easier to handle and mix with other materials. This results in a more uniform and consistent asphalt mixture, which can Lead to better compaction and a smoother road surface.

In addition to improved workability, gelling agents also enhance the durability of bitumen. By increasing the stiffness and elasticity of the asphalt mixture, these additives help to prevent cracking and deformation, even under heavy traffic loads. This results in a longer-lasting road surface that requires less maintenance and repair over time.

Another benefit of using gelling agents in bitumen production is improved resistance to rutting. Rutting, or the formation of depressions in the road surface, is a common issue in asphalt pavements that experience high Levels of traffic. Gelling agents help to increase the resistance of bitumen to deformation, reducing the likelihood of rutting and extending the lifespan of the road.

Furthermore, gelling agents can also improve the overall performance of asphalt mixtures. By enhancing the rheological properties of bitumen, these additives help to create a more stable and consistent material that can withstand a wide range of environmental conditions. This results in a higher-quality road surface that offers better traction, reduced noise levels, and improved Safety for drivers.

In conclusion, gelling agents play a crucial role in enhancing the performance of bitumen in road construction. By improving workability, durability, resistance to rutting, and overall performance, these additives help to create high-quality asphalt mixtures that offer superior performance and longevity. The best Chinese factory for gelling agents in bitumen production is dedicated to developing innovative solutions that meet the specific needs of the road construction industry, making them a trusted partner for asphalt manufacturers looking to improve the quality of their products.

How to Choose the Best Chinese Factory for Gelling Agents for Bitumen

When it comes to choosing the best Chinese factory for gelling agents for bitumen, there are several factors to consider. Bitumen gelling agents are essential in the construction industry for improving the performance and durability of asphalt mixtures. With the increasing demand for high-quality gelling agents, it is crucial to select a reliable and reputable factory that can meet your specific requirements.

One of the most important factors to consider when choosing a Chinese factory for gelling agents for bitumen is the quality of the products. It is essential to ensure that the factory produces gelling agents that meet industry standards and specifications. This can be achieved by conducting thorough research on the factory’s manufacturing processes, quality control measures, and certifications. Look for factories that have a proven track record of producing high-quality gelling agents that have been tested and approved by relevant authorities.

Another important factor to consider is the factory’s production capacity and capabilities. It is essential to choose a factory that can meet your specific requirements in terms of quantity, lead time, and customization options. Consider factors such as the factory’s production capacity, equipment, and workforce to determine if they can handle your order volume and deliver the gelling agents on time. Additionally, inquire about the factory’s ability to customize gelling agents to meet your specific needs and preferences.

Cost is also a crucial factor to consider when choosing a Chinese factory for gelling agents for bitumen. While it is essential to prioritize quality, it is also important to consider the factory’s pricing and payment terms. Compare quotes from different factories to determine which one offers the best value for money. Keep in mind that the cheapest option may not always be the best, as it could compromise on quality. Look for a factory that offers competitive pricing without compromising on the quality of their gelling agents.

Communication and customer service are also key considerations when choosing a Chinese factory for gelling agents for bitumen. It is important to work with a factory that is responsive, transparent, and easy to communicate with. Look for factories that have a dedicated customer service team that can address your inquiries, provide updates on your order, and resolve any issues promptly. Effective communication is essential for ensuring a smooth and successful partnership with the factory.

| No. | Commodity Name |

| 1 | bonding modifiers |

In conclusion, choosing the best Chinese factory for gelling agents for bitumen requires careful consideration of several factors. Prioritize quality by selecting a factory that produces high-quality gelling agents that meet industry standards. Consider the factory’s production capacity, customization options, and pricing to ensure they can meet your specific requirements. Additionally, prioritize communication and customer service to ensure a smooth and successful partnership. By taking these factors into account, you can select a reliable and reputable Chinese factory for gelling agents for bitumen that meets your needs and expectations.