Table of Contents

Exploring the Production Process in a High-Quality Computer LAN Cable Factory

In the digital age, the importance of high-speed, reliable network connections cannot be overstated. At the heart of these connections are Local Area Network (LAN) cables, which facilitate the transmission of data between computers and other network devices. The production of these cables is a meticulous process, carried out in specialized factories. This article aims to explore the production process in a high-quality computer LAN cable factory.

The production process begins with the selection of raw materials. High-quality LAN cables are typically made from Copper or Fiber optics, both of which are known for their excellent conductivity and durability. Copper is often used for shorter distances, while fiber optics are preferred for longer distances due to their ability to transmit data at higher speeds. The raw materials are carefully inspected to ensure they meet the required standards, as any defects can significantly affect the performance of the final product.

Following the selection of raw materials, the next step is the drawing process. This involves reducing the diameter of the copper or fiber optic material to the desired size. The drawn material is then heated and cooled in a controlled Environment to enhance its strength and flexibility. This is a critical step, as the cables must be able to withstand bending and twisting without breaking.

| Number | Product Name |

| 1 | patch cord |

Once the drawing process is complete, the material is insulated. This involves coating the drawn material with a layer of plastic or other insulating material to protect it from environmental factors such as moisture and heat. The insulation also helps to prevent electrical interference, which can disrupt data transmission.

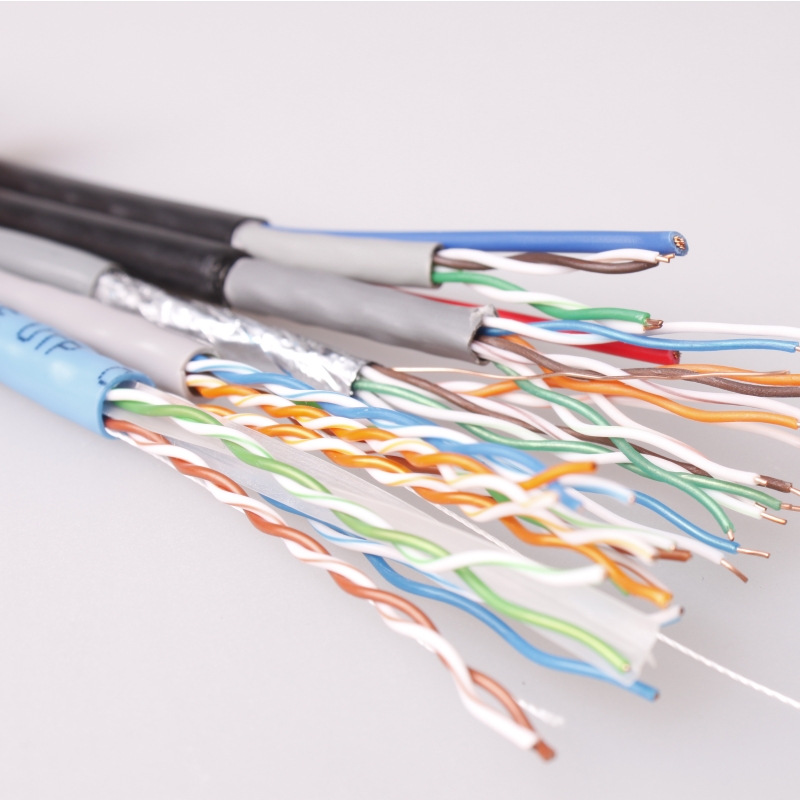

The insulated material is then twisted into pairs. This is done to minimize electromagnetic interference, which can degrade the quality of the signal. The number of twists per inch can vary depending on the type of cable being produced. For instance, Category 5e (Cat5e) cables typically have two to four twists per inch, while Category 6 (Cat6) cables have more twists to support higher data rates.

| No. | Name |

| 1 | Large Electrical Telephone Logarithmic Cable |

After the twisting process, the pairs are bundled together and enclosed in a protective jacket. This jacket not only provides additional protection against environmental factors but also gives the cable its distinctive color. Different colors are used to denote different types of cables. For example, blue is often used for Cat5e cables, while green is used for Cat6 cables.

The final step in the production process is testing. Each cable is rigorously tested to ensure it meets the required performance standards. This includes tests for signal strength, data transmission speed, and resistance to environmental factors. Only cables that pass all tests are approved for sale.

In conclusion, the production of high-quality computer LAN cables is a complex process that requires precision and attention to detail. From the selection of raw materials to the final testing, each step is crucial in ensuring the performance and reliability of the final product. By understanding this process, consumers can make more informed decisions when purchasing LAN cables for their networking needs.