Table of Contents

The Importance of Quality Motorbike Brake Pads

Motorbike brake pads are a crucial component of any motorcycle’s braking system. They play a vital role in ensuring the Safety of the rider and passengers by providing the necessary friction to slow Down or stop the vehicle when needed. As such, the quality of motorbike brake pads is of utmost importance, as any compromise in their performance can Lead to disastrous consequences.

One key factor that determines the quality of motorbike brake pads is the material used in their production. The most common materials used for brake pads are organic, semi-metallic, and ceramic. Each material has its own set of advantages and disadvantages, with some offering better performance in certain conditions than others. For example, organic brake pads are known for their smooth and quiet operation, while semi-metallic pads offer better heat dissipation and durability.

In order to produce high-quality motorbike brake pads, manufacturers must carefully select the appropriate material for the specific application. This involves considering factors such as the type of motorcycle, the rider’s driving style, and the environmental conditions in which the motorcycle will be used. By choosing the right material, manufacturers can ensure that their brake pads provide optimal performance and safety for the rider.

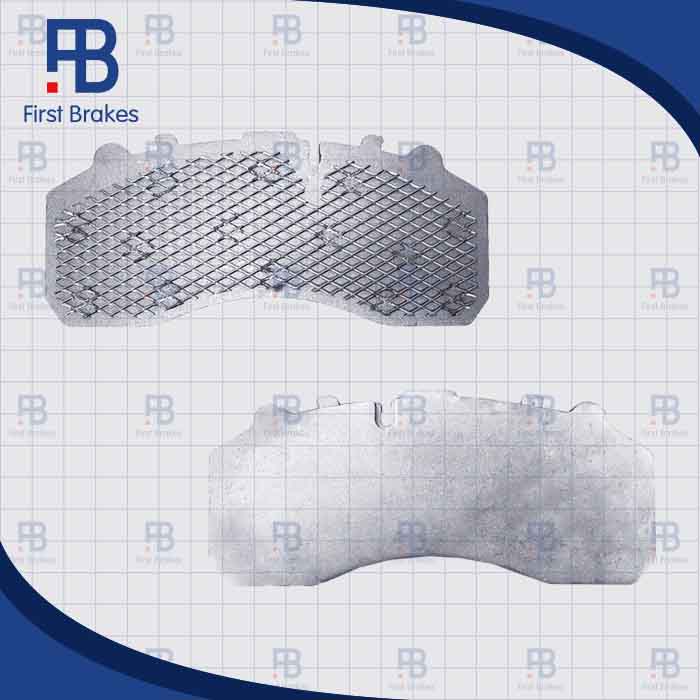

Another important aspect of producing quality motorbike brake pads is the manufacturing process itself. This includes the design of the brake pads, the production of the raw materials, and the assembly of the final product. One key component of the manufacturing process is the use of brake Pad sheet plates, which are used to form the shape of the brake pads and provide the necessary structure and support.

Brake pad sheet plates are typically made from high-quality steel or Aluminum alloy, which are known for their strength and durability. These materials are carefully selected to ensure that they can withstand the high temperatures and pressures that brake pads are subjected to during operation. By using high-quality sheet plates, manufacturers can produce brake pads that are reliable and long-lasting, providing peace of mind to riders who rely on their brakes for safety.

In addition to the material and manufacturing process, the quality of motorbike brake pads is also influenced by the testing and quality control procedures implemented by the manufacturer. Before being released to the market, brake pads undergo rigorous testing to ensure that they meet the required performance standards and safety regulations. This includes testing for factors such as braking efficiency, noise Levels, and wear resistance.

By investing in quality motorbike brake pads, riders can ensure that their motorcycles are equipped with reliable and safe braking systems. Whether riding on city streets or tackling challenging off-road terrain, having high-quality brake pads can make all the difference in ensuring a smooth and safe ride. With the right combination of materials, manufacturing processes, and testing procedures, manufacturers can produce brake pads that meet the highest standards of quality and performance.

In conclusion, the importance of quality motorbike brake pads cannot be overstated. By choosing the right materials, employing effective manufacturing processes, and implementing rigorous testing procedures, manufacturers can produce brake pads that provide optimal performance and safety for riders. Investing in high-quality brake pads is a small price to pay for the peace of mind that comes with knowing that your motorcycle’s braking system is reliable and dependable.