Table of Contents

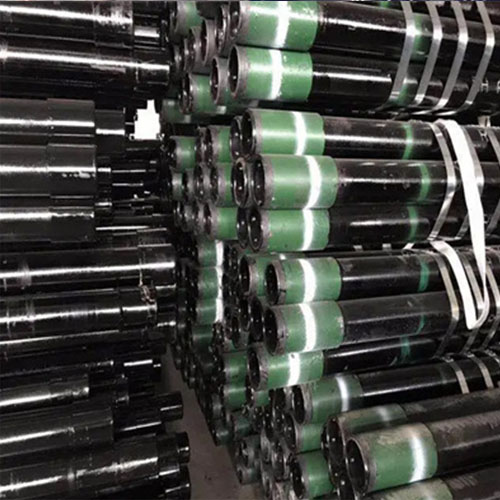

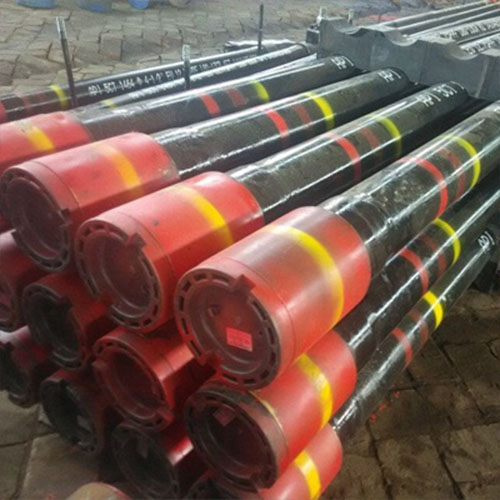

Understanding the Differences Between N80, L80, N80Q, P110 Casing Tubing Seamless Pipe BC/LC

When it comes to oil and gas drilling, the selection of the right casing tubing seamless pipe is crucial for the success of the operation. There are several different grades of casing tubing seamless pipe available, each with its own unique properties and characteristics. In this article, we will explore the differences between N80, L80, N80Q, and P110 casing tubing seamless pipe BC/LC, and how they are used in the oil and gas industry.

N80 casing tubing seamless pipe is a relatively low steel grade in the API 5CT specification. It is commonly used in shallow wells and is known for its high tensile strength and ability to withstand high internal pressure. N80 tubing is also resistant to corrosion and has good mechanical properties, making it a popular choice for a wide range of applications.

L80 casing tubing seamless pipe is a higher steel grade than N80 and is known for its higher tensile strength and improved resistance to corrosion. L80 tubing is often used in medium-depth wells and is suitable for environments with high Levels of CO2 and H2S. It is also commonly used in sour service applications where the wellbore has been exposed to hydrogen sulfide.

N80Q casing tubing seamless pipe is a modified version of N80 with a higher yield strength and better resistance to internal pressure. N80Q tubing is often used in deep wells and is suitable for environments with high levels of CO2 and H2S. It is also commonly used in sour service applications where the wellbore has been exposed to hydrogen sulfide.

P110 casing tubing seamless pipe is a high-strength steel grade with excellent mechanical properties and resistance to corrosion. P110 tubing is commonly used in deep wells and is suitable for environments with high levels of CO2 and H2S. It is also commonly used in sour service applications where the wellbore has been exposed to hydrogen sulfide.

In addition to the different steel grades, casing tubing seamless pipe is also available in two different types of Thread connections: BC (external upset) and LC (internal upset). BC connections are designed for applications where high torque is required, while LC connections are designed for applications where high pressure is a concern.

In conclusion, the selection of the right casing tubing seamless pipe is crucial for the success of oil and gas drilling operations. N80, L80, N80Q, and P110 are all popular steel grades used in the industry, each with its own unique properties and characteristics. Understanding the differences between these grades and their applications is essential for ensuring the Safety and efficiency of drilling operations. By considering factors such as well depth, environmental conditions, and thread connections, operators can make informed decisions about which casing tubing seamless pipe is best suited for their specific needs.