Table of Contents

**1. Exploring the Benefits of Using Perforated Casing Pipe in Oil and Gas Wells**

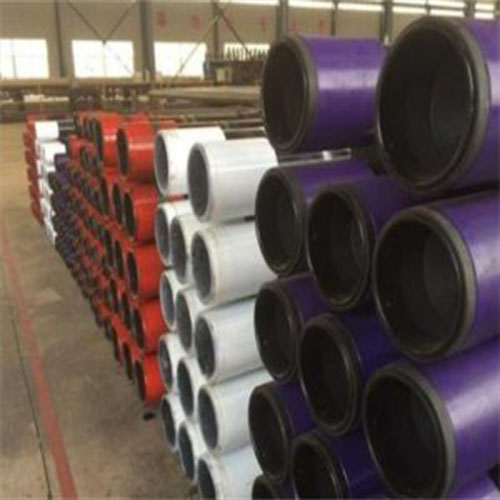

Perforated Casing Pipe/Perforated Pipe / Perforated Nipple Eue/Tubing

1. Exploring the Benefits of Using Perforated Casing Pipe in Oil and Gas Wells

Perforated casing pipe, also known as perforated pipe or perforated nipple EUE/tubing, plays a crucial role in the oil and gas industry. It is designed to enhance the production of oil and gas wells by optimizing the flow of fluids and preventing the influx of unwanted materials. In this section, we will explore the numerous benefits of using perforated casing pipe in oil and gas wells.

One of the primary advantages of using perforated casing pipe is its ability to control the inflow of fluids. The perforations in the pipe allow for the selective entry of oil, gas, and water, ensuring that the desired fluids are extracted efficiently. By controlling the inflow, operators can optimize the production rate and maximize the recovery of hydrocarbons from the reservoir.

Additionally, perforated casing pipe facilitates the prevention of unwanted materials from entering the wellbore. The perforations act as a filter, preventing the entry of Sand, debris, and other solids that could potentially damage the production equipment or hinder the flow of fluids. This helps to maintain the integrity of the well and prolong its lifespan.

Moreover, the use of perforated casing pipe promotes better reservoir management. By controlling the inflow of fluids, operators can effectively manage the pressure differentials within the reservoir. This enables them to optimize production strategies, enhance reservoir sweep efficiency, and maximize the ultimate recovery of hydrocarbons.

Another significant benefit of perforated casing pipe is its versatility. It can be applied in a wide range of wellbore configurations and completion techniques. Whether it’s a vertical, deviated, or horizontal well, perforated casing pipe can be tailored to suit the specific requirements of the well. Furthermore, it can be used in conjunction with other completion tools, such as packers and screens, to further enhance well performance.

Furthermore, the use of perforated casing pipe offers cost-effective solutions for oil and gas operators. By optimizing production rates and maximizing recovery, operators can achieve higher profits and better return on investment. Additionally, the longevity of the wellbore is extended, reducing the need for costly workovers and interventions.

It is worth mentioning that the design and placement of the perforations in the casing pipe are crucial factors that affect its performance. Engineers carefully consider factors such as reservoir characteristics, fluid properties, and wellbore conditions to determine the optimal design for the perforated casing pipe.

In conclusion, the benefits of using perforated casing pipe in oil and gas wells are numerous. From controlling fluid inflow to preventing the entry of unwanted materials, perforated casing pipe plays a

– Discuss the advantages of using perforated casing pipe in oil and gas wells, including its impact on well productivity, fluid flow, and overall efficiency

Perforated Casing Pipe/Perforated Pipe / Perforated Nipple Eue/Tubing

Perforated casing pipe plays a crucial role in the oil and gas industry, where it is used in wells to enhance productivity, optimize fluid flow, and improve overall efficiency. This article will discuss the advantages of using perforated casing pipe in oil and gas wells, highlighting its impact on well productivity, fluid flow, and overall efficiency.

One of the key advantages of perforated casing pipe is its ability to increase well productivity. By allowing fluid to enter the wellbore from the surrounding formation, the perforations in the casing pipe enable the extraction of a larger volume of oil and gas. This increased productivity can have a significant impact on the profitability of a well, making perforated casing pipe a valuable asset for oil and gas operators.

In addition to enhancing well productivity, perforated casing pipe also plays a crucial role in optimizing fluid flow. The perforations in the casing pipe act as pathways for the fluid to flow into the wellbore, ensuring efficient and continuous production. By allowing the fluid to enter the wellbore evenly and at a controlled rate, perforated casing pipe helps to prevent the formation of preferential flow paths that can Lead to uneven production and decreased efficiency.

Moreover, perforated casing pipe has a positive impact on the overall efficiency of oil and gas wells. By optimizing fluid flow and increasing well productivity, the use of perforated casing pipe allows operators to maximize the extraction of oil and gas resources. This leads to higher yields and improved profitability, making perforated casing pipe a cost-effective solution for the oil and gas industry.

Furthermore, the design of perforated casing pipe allows for customization based on specific well conditions and requirements. The size, pattern, and distribution of the perforations can be tailored to meet the unique needs of each well, ensuring optimal fluid flow and production. This flexibility in design makes perforated casing pipe a versatile tool that can be adapted to various well configurations and geological conditions.

Overall, the advantages of using perforated casing pipe in oil and gas wells are manifold. Its impact on well productivity, fluid flow, and overall efficiency cannot be overstated. By increasing well productivity, optimizing fluid flow, and improving overall efficiency, perforated casing pipe plays a crucial role in the success of oil and gas operations. Its ability to enhance production and maximize resource extraction makes it a valuable asset for the industry.

In conclusion, perforated casing pipe is a vital component in the oil and gas industry, offering numerous advantages for well productivity, fluid flow, and overall efficiency. Its ability to increase well productivity, optimize fluid flow, and improve overall efficiency makes it an indispensable tool for oil and