Table of Contents

Benefits of Using Bensonic Ultrasonic Welding Machine for Manufacturing Plastic Welders

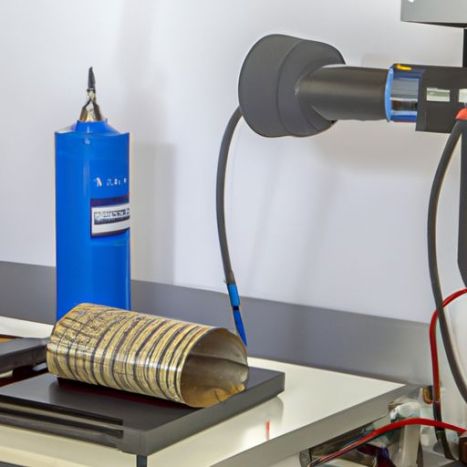

Plastic welding is a common process used in various industries to join plastic components together. One of the most efficient methods of plastic welding is ultrasonic welding, which uses high-frequency ultrasonic vibrations to create heat and bond the materials. Bensonic is a leading manufacturer of ultrasonic welding machines, known for their high-quality and reliable equipment. In this article, we will discuss the benefits of using a Bensonic ultrasonic welding machine for manufacturing plastic welders.

One of the main advantages of using a Bensonic ultrasonic welding machine is its precision and consistency. The machine is able to deliver precise and uniform welds, ensuring that each product meets the required specifications. This level of accuracy is crucial in industries where quality control is paramount, such as medical device manufacturing or automotive production.

In addition to precision, Bensonic ultrasonic welding machines are also known for their speed and efficiency. The machines can complete welds in a fraction of the time it would take using traditional welding methods, allowing manufacturers to increase their production output and reduce overall costs. This makes Bensonic ultrasonic welding machines a cost-effective solution for companies looking to streamline their manufacturing processes.

Another benefit of using a Bensonic ultrasonic welding machine is the versatility it offers. The machines can be used to weld a wide range of plastic materials, including thermoplastics, composites, and even some metals. This flexibility makes Bensonic ultrasonic welding machines suitable for a variety of applications, from electronics and packaging to automotive and aerospace.

Furthermore, Bensonic ultrasonic welding machines are easy to operate and maintain. The machines are designed with user-friendly interfaces and intuitive controls, making them accessible to operators of all skill Levels. Additionally, Bensonic offers comprehensive training and support services to help manufacturers get the most out of their equipment.

One of the key advantages of using a Bensonic ultrasonic welding machine is the cost savings it can provide. The machines are energy-efficient and require minimal consumables, reducing operating costs in the long run. Additionally, the high-speed capabilities of Bensonic ultrasonic welding machines can help manufacturers save on labor costs and increase overall productivity.

Overall, Bensonic ultrasonic welding machines offer a range of benefits for manufacturers looking to improve their plastic welding processes. From precision and speed to versatility and cost savings, these machines are a reliable and efficient solution for a wide range of industries. If you are in the market for a plastic welder, consider investing in a Bensonic ultrasonic welding machine for optimal results.