Table of Contents

Benefits of Using Thermal Asphalt Blend Additives

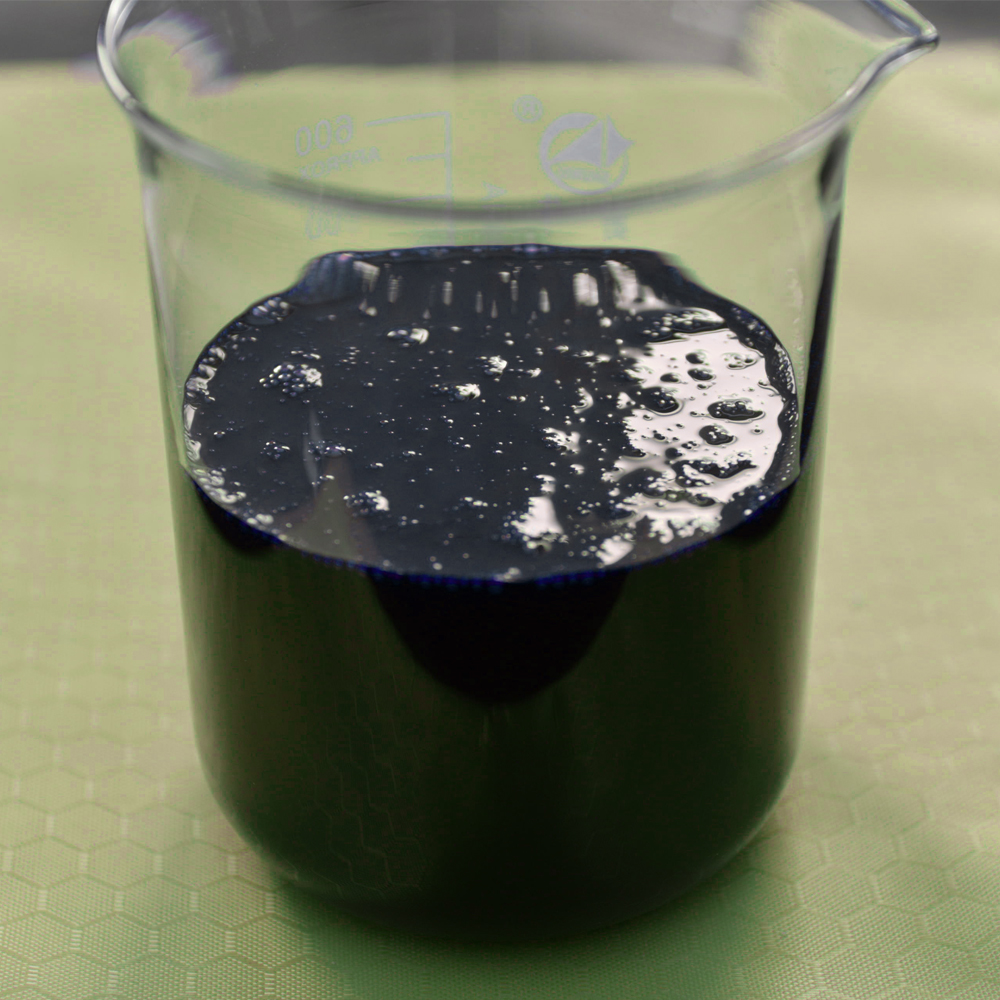

Thermal asphalt blend additives, also known as warm mix pavement enhancers or warm mix asphalt modifiers, are a type of additive that can be mixed with asphalt to lower the temperature at which the asphalt can be mixed and compacted. This technology has gained popularity in recent years due to its numerous benefits in terms of cost savings, environmental impact, and overall performance of the pavement.

One of the key benefits of using thermal asphalt blend additives is the reduction in energy consumption during the production and placement of asphalt. Traditional hot mix asphalt requires high temperatures to be mixed and compacted, which can be energy-intensive and costly. By using warm mix additives, the temperature at which the asphalt can be mixed and compacted is lowered, resulting in significant energy savings. This not only reduces the carbon footprint of the pavement construction process but also helps to lower costs for contractors and agencies.

In addition to energy savings, thermal asphalt blend additives also offer improved workability and compaction of the asphalt mixture. The lower mixing temperatures allow for better coating of the aggregate particles with the asphalt binder, resulting in a more uniform and durable pavement. This can Lead to reduced rutting, cracking, and other forms of distress in the pavement, ultimately extending the service life of the road.

Furthermore, warm mix additives can help to reduce emissions of harmful pollutants during the production and placement of asphalt. The lower temperatures required for mixing and compacting asphalt result in reduced emissions of volatile organic compounds (VOCs) and greenhouse gases. This can have a positive impact on air quality and public health, making warm mix technology a more sustainable option for pavement construction.

| Part | Product Name |

| 1 | Warm asphalt mixture constituents |

Another benefit of using thermal asphalt blend additives is the ability to extend the paving season in colder climates. Traditional hot mix asphalt is typically limited to warmer months when temperatures are conducive to mixing and compacting the asphalt. With warm mix technology, contractors can continue paving operations into the shoulder seasons when temperatures are cooler. This can help to expedite construction schedules and reduce downtime, ultimately saving time and money for agencies and contractors.

Overall, the use of thermal asphalt blend additives offers a wide range of benefits for pavement construction. From cost savings and environmental impact to improved performance and extended paving seasons, warm mix technology has become a valuable tool for agencies and contractors looking to enhance the quality and sustainability of their pavement projects. By incorporating warm mix additives into their asphalt mix designs, stakeholders can achieve better results in terms of durability, workability, and environmental stewardship.