Table of Contents

Can Wire Cable Be Welded in Stainless Steel Wire Rope Assemblies?

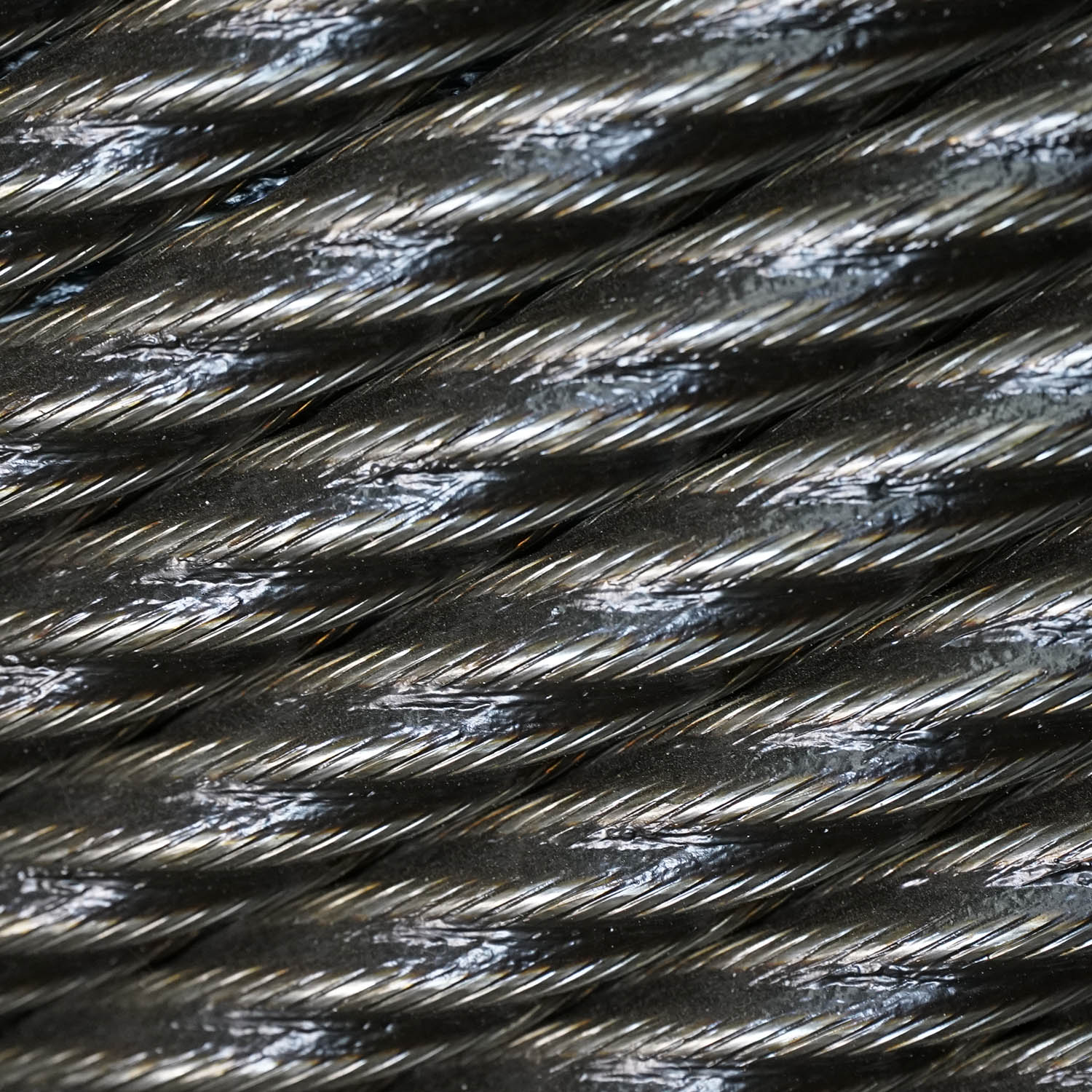

Stainless steel wire rope assemblies are commonly used in a variety of industries for their strength, durability, and resistance to corrosion. These assemblies are made up of individual wire cables that are twisted or braided together to form a strong and flexible rope. One question that often arises when working with stainless steel wire rope assemblies is whether or not the wire cables can be welded together.

Welding stainless steel wire cables in a wire rope assembly can be a complex process that requires careful consideration of the materials being used and the specific requirements of the application. While it is possible to weld stainless steel wire cables together, there are some important factors to consider before attempting to do so.

One of the main challenges of welding stainless steel wire cables is the high carbon content of the material. This can make the cables more prone to cracking or breaking during the welding process, especially if the cables are not properly prepared or if the welding is not done correctly. It is important to use the proper welding techniques and equipment to ensure a strong and reliable weld.

Another factor to consider when welding stainless steel wire cables is the potential for corrosion. Stainless steel is known for its resistance to corrosion, but welding can introduce new areas of vulnerability where corrosion can occur. It is important to use the proper welding materials and techniques to minimize the risk of corrosion and ensure the longevity of the wire rope assembly.

When welding stainless steel wire cables, it is also important to consider the overall strength and integrity of the assembly. Welding can introduce stress and heat into the cables, which can affect their strength and flexibility. It is important to carefully monitor the welding process and test the strength of the assembly to ensure that it meets the necessary requirements for the application.

In some cases, it may be more practical to use other methods of joining stainless steel wire cables in a wire rope assembly, such as crimping or swaging. These methods can provide a strong and reliable connection without the potential risks associated with welding. It is important to carefully consider the specific requirements of the application and choose the best method of joining the wire cables based on those requirements.

In conclusion, while it is possible to weld stainless steel wire cables in a wire rope assembly, there are some important factors to consider before attempting to do so. It is important to use the proper welding techniques and equipment, consider the potential for corrosion, and ensure the overall strength and integrity of the assembly. In some cases, it may be more practical to use other methods of joining the wire cables, such as crimping or swaging. By carefully considering these factors and choosing the best method for the application, you can ensure a strong and reliable wire rope assembly that meets your specific needs.