Table of Contents

Steel Wire Load Capacity: Factors to Consider

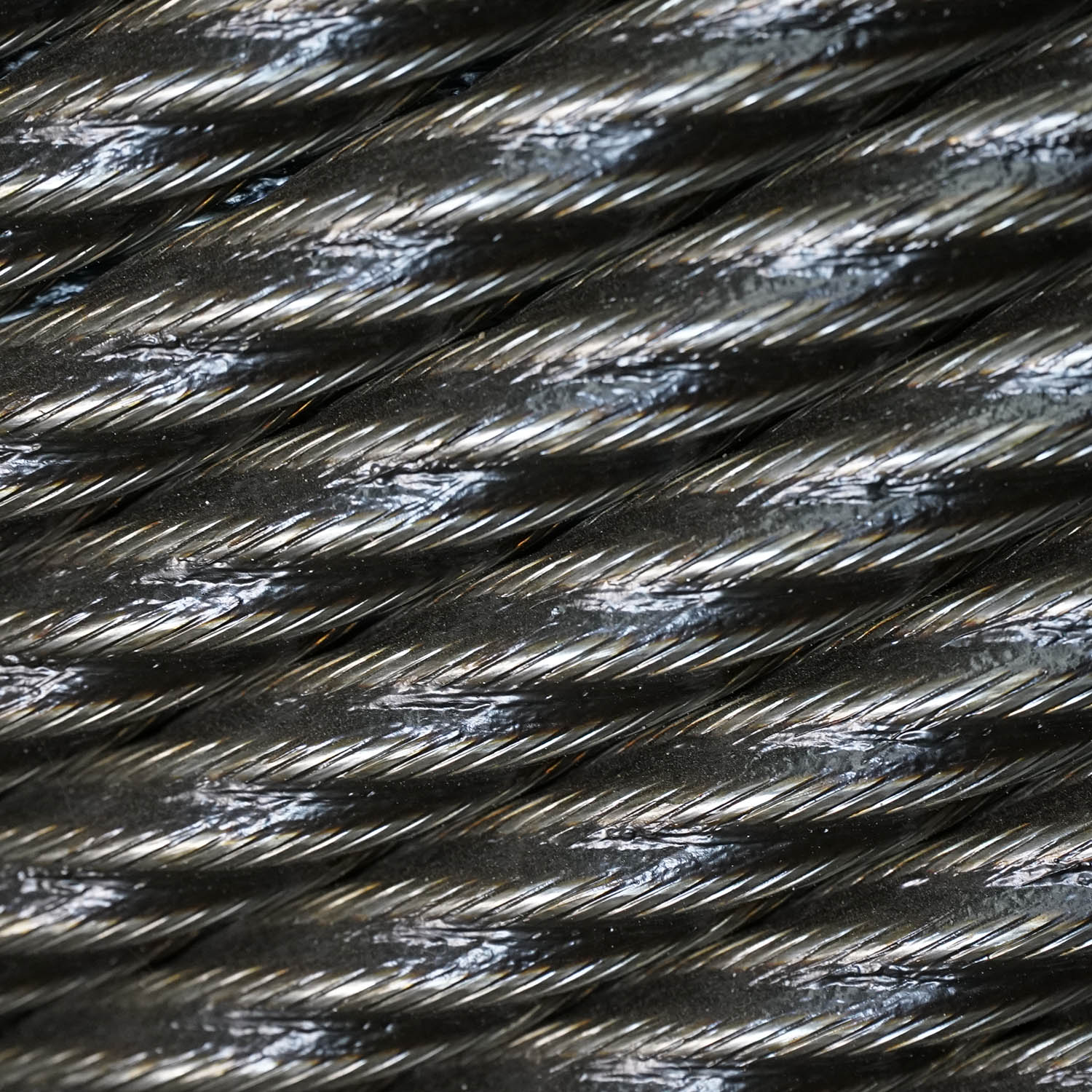

Steel wire is a versatile material that is commonly used in various industries for its strength and durability. When it comes to determining the load capacity of steel wire, there are several factors that need to be taken into consideration. Understanding these factors is crucial in ensuring the safe and efficient use of steel wire in different applications.

One of the key factors that determine the load capacity of steel wire is its diameter. The thicker the wire, the higher its load capacity will be. This is because thicker wires have more material and therefore can support heavier loads. It is important to carefully consider the diameter of the steel wire when selecting it for a specific application to ensure that it can handle the required load.

Another important factor to consider is the material composition of the steel wire. Different types of steel have different properties, such as tensile strength and elasticity, which can affect the load capacity of the wire. It is essential to choose a steel wire that is appropriate for the specific application to ensure that it can withstand the required load without breaking or deforming.

The length of the steel wire also plays a role in determining its load capacity. Longer wires are more prone to sagging and stretching under heavy loads, which can reduce their load capacity. It is important to consider the length of the wire and the distance between support points when calculating the load capacity to ensure that the wire can support the required load without failing.

In addition to these factors, the Environment in which the steel wire will be used can also impact its load capacity. Factors such as temperature, humidity, and exposure to corrosive substances can affect the strength and durability of the wire. It is important to consider the environmental conditions in which the wire will be used and select a steel wire that is suitable for those conditions to ensure its load capacity is not compromised.

When using steel wire in applications where it will be subjected to heavy loads, it is essential to calculate the load capacity accurately to prevent accidents and ensure the Safety of personnel and equipment. Consulting with a professional engineer or using load capacity Calculators can help determine the maximum load that a specific steel wire can safely support.

In conclusion, the load capacity of steel wire is determined by several factors, including its diameter, material composition, length, and environmental conditions. Understanding these factors and carefully considering them when selecting steel wire for a specific application is crucial in ensuring its safe and efficient use. By taking these factors into account, you can ensure that the steel wire will be able to support the required load without failing.

How to Determine the Load Capacity of Steel Wire

Steel wire is a versatile material that is commonly used in a variety of applications, from construction to crafting. One important consideration when using steel wire is its load capacity, or the maximum weight it can support without breaking. Determining the load capacity of steel wire is essential to ensure the safety and stability of any structure or project it is used in.

The load capacity of steel wire is determined by several factors, including the diameter of the wire, the material it is made from, and the type of load it will be subjected to. Thicker wires generally have a higher load capacity than thinner wires, as they are able to support more weight without breaking. Additionally, steel wire is known for its strength and durability, making it a popular choice for applications where a high load capacity is required.

To determine the load capacity of a specific type of steel wire, it is important to consult the manufacturer’s specifications. These specifications will provide information on the wire’s diameter, material composition, and load capacity, allowing you to select the appropriate wire for your needs. It is also important to consider the type of load the wire will be subjected to, as different types of loads (such as tension, compression, or bending) will require different load capacities.

In addition to consulting manufacturer specifications, there are also formulas and guidelines that can be used to calculate the load capacity of steel wire. One common method is to use the ultimate tensile strength of the wire, which is the maximum amount of stress it can withstand before breaking. By dividing the ultimate tensile strength by a safety factor (typically 1.5 to 2), you can determine the safe working load of the wire.

It is important to note that the load capacity of steel wire can also be affected by external factors, such as temperature, corrosion, and fatigue. High temperatures can weaken the wire and reduce its load capacity, while corrosion can cause the wire to deteriorate over time. Additionally, repeated bending or flexing of the wire can Lead to fatigue failure, reducing its load capacity.

In conclusion, determining the load capacity of steel wire is essential for ensuring the safety and stability of any project or structure it is used in. By consulting manufacturer specifications, using formulas to calculate load capacity, and considering external factors that can affect the wire’s strength, you can select the appropriate wire for your needs. Whether you are building a bridge, hanging a picture frame, or crafting a piece of Jewelry, understanding the load capacity of steel wire is crucial for a successful and safe outcome.

Will Steel Wool Scratch Silver? Tips for Safely Cleaning Silver Items

When it comes to cleaning silver items, many people are unsure of the best methods to use. One common question that arises is whether steel wool will scratch silver. In this article, we will explore the load capacity of steel wire and whether steel wool is safe to use on silver items.

Steel wire is a versatile material that is commonly used in a variety of applications, including construction, manufacturing, and household cleaning. The load capacity of steel wire refers to the maximum amount of weight that it can support without breaking. This is an important factor to consider when using steel wire for any purpose, as exceeding the load capacity can result in damage or injury.

When it comes to cleaning silver items, many people turn to steel wool as a cleaning agent. Steel wool is made from fine steel fibers that are woven together to create a dense, abrasive material. While steel wool is effective at removing tough stains and grime, it can also scratch delicate surfaces, such as silver.

Silver is a soft metal that is prone to scratching, so it is important to use caution when cleaning silver items. While steel wool may be effective at removing tarnish and dirt from silver, it can also leave behind unsightly scratches that can diminish the appearance of the item.

To safely clean silver items without risking damage from steel wool, there are a few tips to keep in mind. First, always use a gentle cleaning solution that is specifically designed for silver. Avoid harsh Chemicals or abrasive materials that can scratch or tarnish the silver.

When cleaning silver items, use a soft Cloth or Sponge to gently buff away tarnish and dirt. Avoid using steel wool or other abrasive materials that can scratch the surface of the silver. If necessary, you can use a silver polishing cloth or a mild silver polish to restore the shine to your silver items.

If you do choose to use steel wool to clean silver items, proceed with caution. Start by testing a small, inconspicuous area of the silver to ensure that the steel wool does not cause any damage. If you notice any scratching or dulling of the surface, stop immediately and switch to a gentler cleaning method.

In conclusion, while steel wool is a versatile cleaning material, it is not recommended for use on silver items. The abrasive nature of steel wool can scratch and damage the delicate surface of silver, leaving behind unsightly marks. To safely clean silver items, use a gentle cleaning solution and a soft cloth to buff away tarnish and dirt. By following these tips, you can keep your silver items looking shiny and new for years to come.