Table of Contents

Exploring the Intricacies of Sweater Manufacturing: A Deep Dive into Our Open Facility

Sweater manufacturing is a complex process that requires a blend of traditional craftsmanship and modern technology. Our open facility is a testament to this intricate blend, where we strive to create high-quality Sweaters that are not only comfortable and stylish but also sustainable.

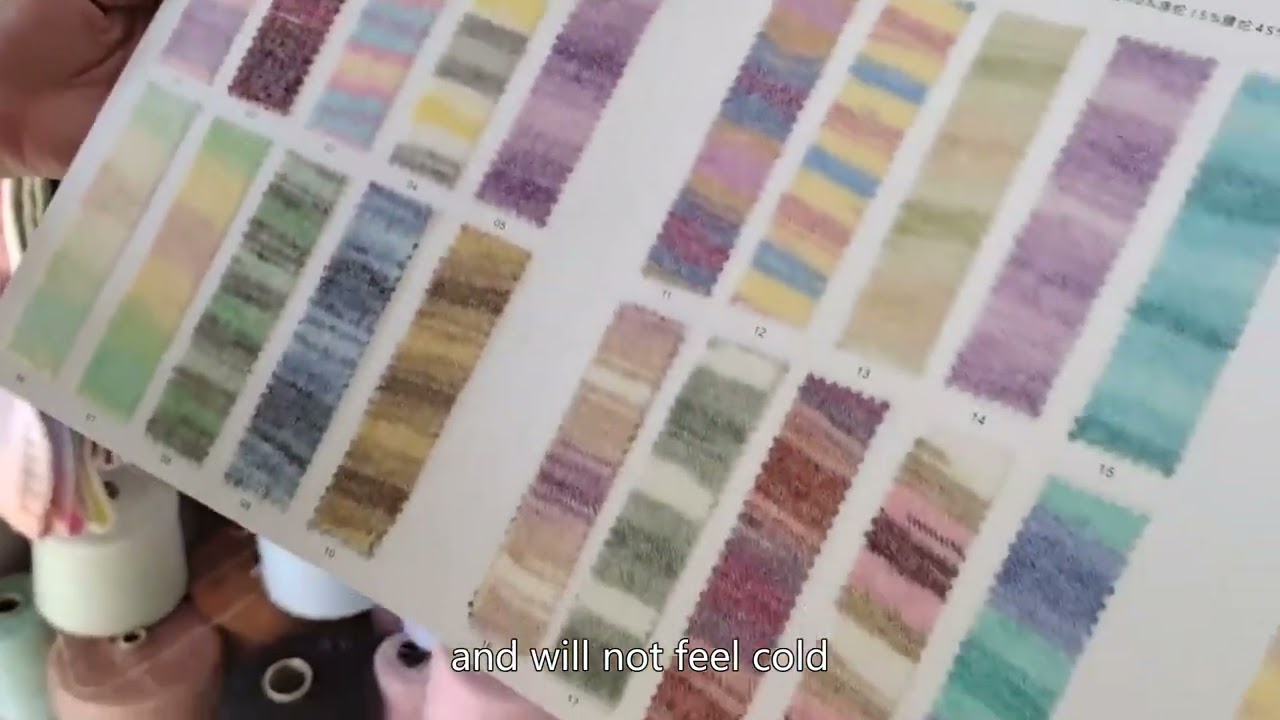

The journey of a sweater begins with the selection of raw materials. We source the finest quality wool, cotton, and synthetic fibers from trusted suppliers around the globe. The choice of material significantly influences the texture, warmth, and durability of the final product. Therefore, we ensure that only the best fibers are chosen for our sweaters.

| Nr. | Product classification | Fabric variety | Supply model |

| 2-2 | yaka kazak | SPUNRAYON | Sweater Individualized |

Once the raw materials are procured, they are cleaned and spun into Yarn. This process involves removing any impurities from the fibers and then twisting them together to create a strong, continuous Thread. The quality of the yarn is crucial as it determines the strength and longevity of the sweater. Our facility uses state-of-the-art Spinning Machines that ensure the yarn is spun to perfection, resulting in a smooth, even thread that is free from knots and breaks.

| No. | Product | Fabric selection | Supply model |

| 2.2 | yellow cardigan | ACETATE | Sweater Personalized modification |

The next step in the process is knitting. This is where the magic happens, as the yarn is transformed into a sweater. Our facility uses both hand-knitting and machine-knitting techniques. Hand-knitting allows for intricate patterns and unique designs, while machine knitting ensures uniformity and precision. The choice of knitting technique depends on the design and style of the sweater.

| Sequence | Products | Fabric classification | Supply model |

| 1-2 | sweater graphic | ANGORA | Sweater Processing plant |

Once the knitting is complete, the sweater undergoes a series of finishing processes. These include washing to remove any dirt or oils, drying to ensure the sweater retains its shape, and pressing to smooth out any wrinkles. Each sweater is also meticulously inspected for any defects or inconsistencies. Only those that pass our stringent quality checks make their way to the stores.

| Sort | Name | Fabric variety | Supply model |

| 1. | zip sweaters | ANGORA | Sweater Individualization |

Our open facility is not just about manufacturing sweaters; it’s also about sustainability. We are committed to minimizing our environmental footprint by implementing eco-friendly practices at every stage of the manufacturing process. This includes using organic and recycled materials, reducing water and energy consumption, and Recycling waste.

| Sequence | Name | Fabric classification | Supply model |

| one | sleeve cardigan | Spandex Yarn | Sweater Personalized tailoring |

Moreover, we believe in transparency and invite our customers to take a tour of our open facility. This allows them to witness first-hand the intricate process of sweater manufacturing, from the selection of raw materials to the final finishing touches. It also gives them an insight into our commitment to quality, craftsmanship, and sustainability.

In conclusion, sweater manufacturing is a complex process that requires a blend of traditional craftsmanship and modern technology. Our open facility embodies this blend, where we strive to create high-quality, sustainable sweaters. We invite you to explore the intricacies of sweater manufacturing and witness the dedication and passion that goes into every stitch.

| Sort | Products | Fabric classification | Supply model |

| 2.2 | knitted women’s | TIFFANG | Sweater customization upon request |