Table of Contents

Benefits of Using Liquid Anti-Stripping Agent in Asphalt Pavements

Asphalt pavements are a common feature of our roadways, providing a smooth and durable surface for vehicles to travel on. However, over time, these pavements can deteriorate due to a variety of factors, including moisture infiltration and the effects of traffic. One of the key issues that can affect the performance of asphalt pavements is stripping, which occurs when the bond between the asphalt binder and the aggregate is weakened, leading to the loss of adhesion and ultimately the failure of the pavement.

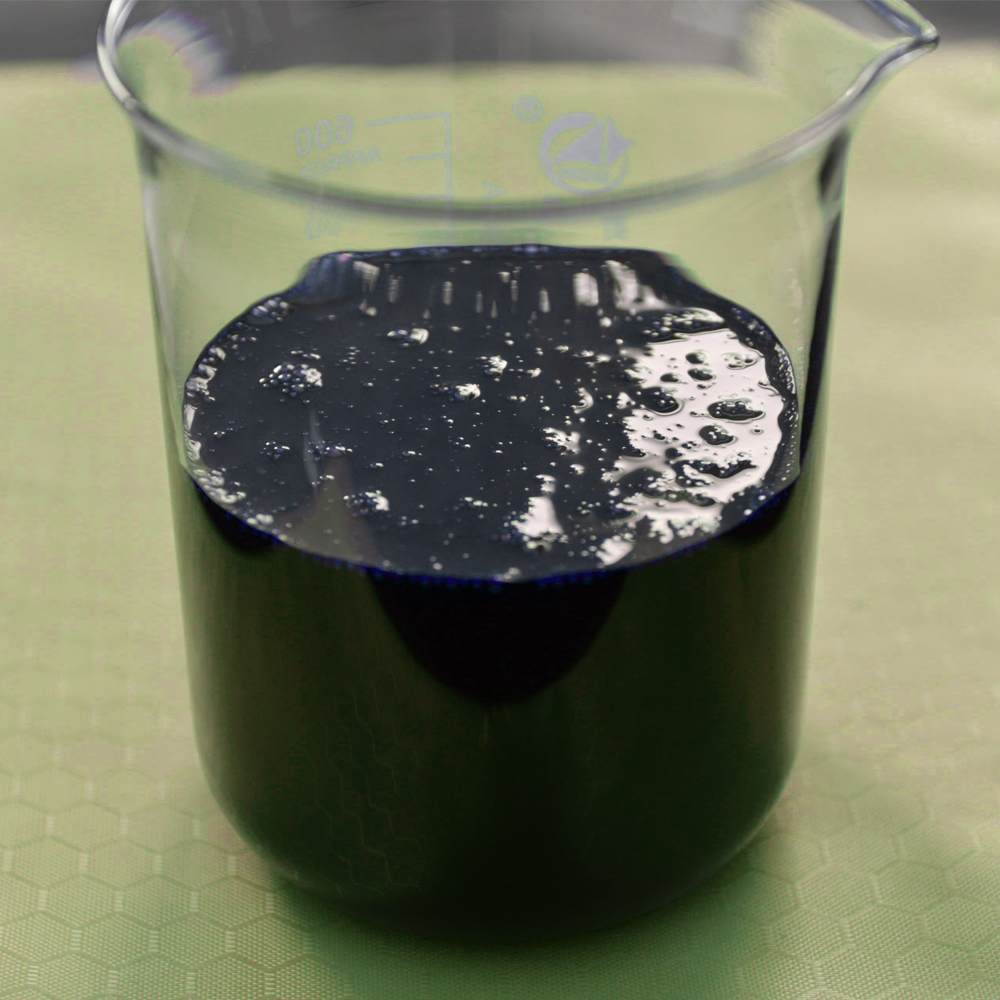

To address this issue, liquid anti-stripping agents have been developed as a solution to improve the bond between the asphalt binder and the aggregate. These agents are designed to enhance the adhesion properties of the asphalt mixture, preventing the stripping phenomenon and improving the overall performance and durability of the pavement.

| Serial Number | Item |

| 1 | asphalt Anti-strip agent |

One of the key benefits of using a liquid anti-stripping agent in asphalt pavements is the improved bond strength between the asphalt binder and the aggregate. By enhancing the adhesion properties of the asphalt mixture, these agents help to create a stronger and more durable pavement that is better able to withstand the effects of traffic and environmental factors. This can help to extend the service life of the pavement and reduce the need for costly repairs and maintenance.

In addition to improving bond strength, liquid anti-stripping agents can also help to reduce the risk of moisture infiltration into the pavement. Moisture is a major contributor to the stripping phenomenon, as it can weaken the bond between the asphalt binder and the aggregate, leading to premature pavement failure. By enhancing the adhesion properties of the asphalt mixture, these agents help to create a more water-resistant pavement that is better able to withstand the effects of moisture infiltration.

Another benefit of using a liquid anti-stripping agent in asphalt pavements is the improved resistance to rutting and cracking. Rutting and cracking are common forms of pavement distress that can occur as a result of traffic loading and environmental factors. By enhancing the adhesion properties of the asphalt mixture, these agents help to create a more flexible and resilient pavement that is better able to resist the effects of rutting and cracking, leading to a longer-lasting and more durable pavement.

Overall, the use of liquid anti-stripping agents in asphalt pavements offers a range of benefits that can help to improve the performance and durability of the pavement. By enhancing bond strength, reducing the risk of moisture infiltration, and improving resistance to rutting and cracking, these agents can help to extend the service life of the pavement and reduce the need for costly repairs and maintenance. For these reasons, liquid anti-stripping agents are an important tool in the maintenance and preservation of asphalt pavements, helping to ensure that our roadways remain safe and reliable for years to come.

How Surface Adhesion Agents Improve the Performance of Bitumen Bonding Agents

Surface adhesion agents play a crucial role in enhancing the performance of bitumen bonding agents. These agents are designed to improve the adhesion between bitumen and various surfaces, ultimately leading to a stronger and more durable bond. By incorporating surface adhesion agents into bitumen bonding agents, manufacturers can ensure that their products adhere effectively to a wide range of substrates, including asphalt, concrete, and metal.

One of the key benefits of using surface adhesion agents is their ability to prevent stripping, which occurs when the bond between bitumen and a surface fails, leading to premature pavement failure. Liquid anti-stripping agents are commonly used in bitumen bonding agents to improve adhesion and prevent stripping. These agents work by chemically modifying the surface of the aggregate, creating a stronger bond with the bitumen. By reducing the likelihood of stripping, liquid anti-stripping agents help to prolong the life of pavement surfaces and reduce maintenance costs.

In addition to preventing stripping, surface adhesion agents also improve the overall performance of bitumen bonding agents by enhancing their flexibility and durability. Bitumen is a highly viscous material that can become brittle over time, especially in cold weather conditions. By adding surface adhesion agents to bitumen bonding agents, manufacturers can improve the flexibility of the material, allowing it to withstand temperature fluctuations and traffic loads without cracking or breaking. This increased flexibility also helps to reduce the risk of rutting and other forms of pavement distress.

Surface adhesion agents can also improve the waterproofing properties of bitumen bonding agents, helping to protect pavement surfaces from water damage. When bitumen is applied to a surface, it forms a waterproof barrier that prevents water from seeping into the underlying layers. However, if the bond between the bitumen and the surface is weak, water can penetrate the pavement, leading to potholes, cracks, and other forms of deterioration. By enhancing the adhesion between bitumen and the surface, surface adhesion agents help to create a more effective waterproofing barrier, reducing the risk of water damage and extending the life of the pavement.

Another important benefit of using surface adhesion agents in bitumen bonding agents is their ability to improve the overall performance of the pavement surface. By creating a stronger bond between the bitumen and the surface, these agents help to distribute traffic loads more evenly, reducing the risk of rutting and other forms of pavement distress. This improved performance not only extends the life of the pavement but also enhances Safety for drivers and pedestrians.

In conclusion, surface adhesion agents play a critical role in improving the performance of bitumen bonding agents. By preventing stripping, enhancing flexibility and durability, improving waterproofing properties, and enhancing overall pavement performance, these agents help to create stronger, more durable, and longer-lasting pavement surfaces. Manufacturers and contractors can benefit from incorporating surface adhesion agents into their bitumen bonding agents, ensuring that their products adhere effectively to a wide range of surfaces and deliver superior performance in a variety of conditions.