Table of Contents

Potential Environmental Impact of Drilling in The Lomashkin Oil Field

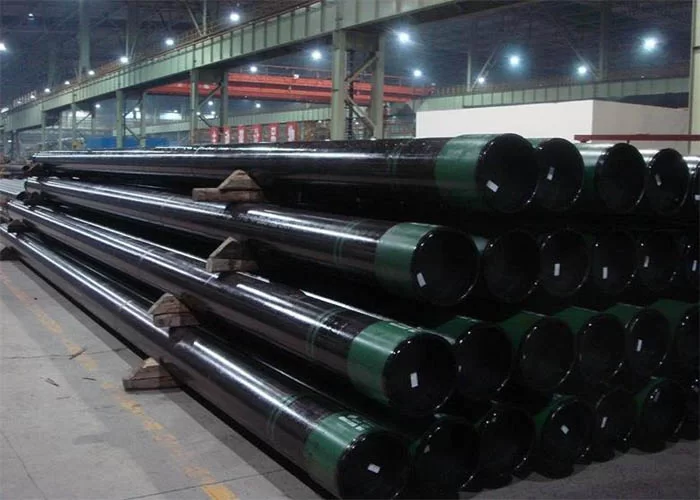

The Lomashkin Oil Field is a significant source of oil reserves located in a remote area. The extraction of oil from this field requires the use of specialized equipment, including casing pipes. The 13 3/8″ 68lb/FT hot rolled casing pipe API 5CT J55/K55 339.72*12.19mm R3 is commonly used in drilling operations in this field. While the extraction of oil is essential for meeting energy demands, it also raises concerns about the potential environmental impact of drilling in the Lomashkin Oil Field.

One of the primary environmental concerns associated with drilling in the Lomashkin Oil Field is the risk of groundwater contamination. The drilling process involves the injection of various Chemicals and fluids into the ground to facilitate the extraction of oil. If these chemicals leak or spill, they can seep into the groundwater, contaminating Drinking Water sources and harming aquatic ecosystems. The use of casing pipes like the 13 3/8″ 68lb/FT hot rolled casing pipe API 5CT J55/K55 339.72*12.19mm R3 is crucial in preventing such leaks and ensuring the integrity of the well.

In addition to groundwater contamination, drilling in the Lomashkin Oil Field can also Lead to habitat destruction. The construction of drilling rigs, access roads, and pipelines can disrupt natural habitats and fragment wildlife populations. This can have long-lasting effects on local ecosystems, leading to a loss of biodiversity and ecosystem services. Proper planning and mitigation measures are essential to minimize the impact of drilling activities on the Environment.

Air pollution is another significant concern associated with drilling in the Lomashkin Oil Field. The combustion of fossil fuels during drilling operations releases pollutants such as carbon dioxide, methane, and volatile organic compounds into the atmosphere. These pollutants contribute to climate change, smog formation, and respiratory illnesses in nearby communities. The use of advanced technologies and best practices, along with the proper maintenance of equipment like the 13 3/8″ 68lb/FT hot rolled casing pipe API 5CT J55/K55 339.72*12.19mm R3, can help reduce emissions and minimize air pollution.

Furthermore, the disposal of drilling waste poses a challenge in the Lomashkin Oil Field. The extraction of oil generates large quantities of waste materials, including drilling muds, cuttings, and produced water. Improper disposal of these wastes can contaminate soil and water resources, posing risks to human health and the environment. It is essential for operators to adhere to strict regulations and guidelines for the safe handling and disposal of drilling waste to prevent environmental harm.

Despite these environmental challenges, the extraction of oil from the Lomashkin Oil Field plays a crucial role in meeting global energy demands. It is essential for operators to prioritize environmental protection and sustainability in their drilling operations. By implementing best practices, using advanced technologies, and investing in environmental monitoring and remediation efforts, the potential environmental impact of drilling in the Lomashkin Oil Field can be minimized.

In conclusion, the 13 3/8″ 68lb/FT hot rolled casing pipe API 5CT J55/K55 339.72*12.19mm R3 is a vital component in drilling operations in the Lomashkin Oil Field. While oil extraction is essential for meeting energy needs, it also raises concerns about groundwater contamination, habitat destruction, air pollution, and waste disposal. By adopting responsible practices and technologies, operators can mitigate the environmental impact of drilling in the Lomashkin Oil Field and ensure the long-term sustainability of this valuable resource.

Advantages and Disadvantages of Using 13 3/8 68lb/FT Hot Rolled Casing Pipe API 5CT J55/K55 339.72*12.19mm R3 in Oil Field Operations

The Lomashkin Oil Field is a well-known oil field located in a remote area, where the extraction of oil is a challenging task. In order to extract oil efficiently, the use of high-quality casing pipes is essential. One popular choice for casing pipes in oil field operations is the 13 3/8″ 68lb/FT Hot Rolled Casing Pipe API 5CT J55/K55 339.72*12.19mm R3. This type of casing pipe has both advantages and disadvantages that should be considered before using it in oil field operations.

One of the main advantages of using the 13 3/8″ 68lb/FT Hot Rolled Casing Pipe API 5CT J55/K55 339.72*12.19mm R3 is its durability. This type of casing pipe is made from high-quality materials that can withstand the harsh conditions of oil field operations. It is designed to resist corrosion and erosion, making it a reliable choice for long-term use in oil extraction.

Another advantage of the 13 3/8″ 68lb/FT Hot Rolled Casing Pipe API 5CT J55/K55 339.72*12.19mm R3 is its versatility. This type of casing pipe can be used in a variety of well depths and drilling conditions, making it a versatile option for oil field operations. It can be easily installed and removed, making it a convenient choice for oil field operators.

In addition to its durability and versatility, the 13 3/8″ 68lb/FT Hot Rolled Casing Pipe API 5CT J55/K55 339.72*12.19mm R3 also offers good performance in terms of oil extraction. This type of casing pipe is designed to provide a tight seal, preventing leaks and ensuring efficient oil extraction. It can withstand high pressure and temperature, making it a reliable choice for oil field operations.

Despite its many advantages, the 13 3/8″ 68lb/FT Hot Rolled Casing Pipe API 5CT J55/K55 339.72*12.19mm R3 also has some disadvantages that should be taken into consideration. One of the main disadvantages of this type of casing pipe is its cost. The high-quality materials used in its construction make it a more expensive option compared to other types of casing pipes.

https://www.youtube.com/watch?v=J1ao9j7SS_Y

Another disadvantage of the 13 3/8″ 68lb/FT Hot Rolled Casing Pipe API 5CT J55/K55 339.72*12.19mm R3 is its weight. This type of casing pipe is heavier than other options, making it more difficult to transport and install in oil field operations. It may require special equipment and machinery to handle its weight, adding to the overall cost of using this type of casing pipe.

In conclusion, the 13 3/8″ 68lb/FT Hot Rolled Casing Pipe API 5CT J55/K55 339.72*12.19mm R3 has both advantages and disadvantages that should be carefully considered before using it in oil field operations. While it offers durability, versatility, and good performance in oil extraction, it also comes with a higher cost and weight compared to other options. Oil field operators should weigh these factors carefully to determine if this type of casing pipe is the right choice for their operations.