Table of Contents

Benefits of Using Anti Stripping Agents in Bitumen

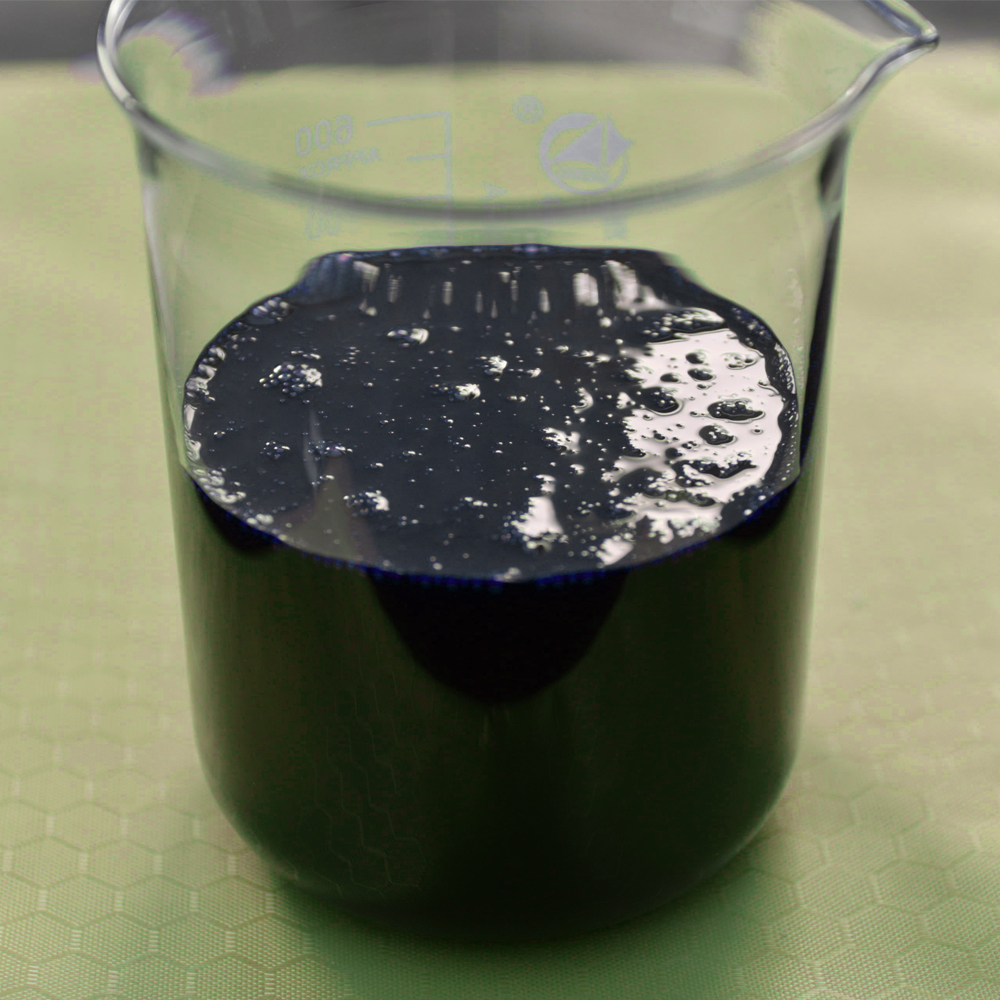

Bitumen, also known as asphalt, is a crucial component in the construction of roads, highways, and other infrastructure projects. It provides durability and strength to the pavement, ensuring that it can withstand heavy traffic and harsh weather conditions. However, one common issue that can arise with bitumen is stripping, which occurs when the bond between the bitumen and the aggregate weakens, leading to pavement failure.

To combat this problem, anti-stripping agents are often used in bitumen mixtures. These agents work by improving the adhesion between the bitumen and the aggregate, ensuring that the pavement remains intact and durable. There are several benefits to using anti-stripping agents in bitumen, which we will explore in this article.

One of the primary benefits of using anti-stripping agents is improved pavement performance. When the bond between the bitumen and the aggregate is strengthened, the pavement is better able to withstand the stresses of heavy traffic and harsh weather conditions. This can help to extend the lifespan of the pavement, reducing the need for costly repairs and maintenance in the future.

| Serial Number | Product Name |

| 1 | Bitumen bonding agent agent |

Additionally, anti-stripping agents can help to improve the overall quality of the pavement. By ensuring that the bitumen and aggregate bond properly, the pavement will have a smoother surface and better resistance to rutting and cracking. This can Lead to a safer and more comfortable driving experience for motorists, as well as reduced noise Levels and improved fuel efficiency.

Another benefit of using anti-stripping agents in bitumen is increased durability. When the bond between the bitumen and the aggregate is strong, the pavement is less likely to experience premature failure due to stripping. This can help to reduce the need for frequent repairs and resurfacing, saving time and money in the long run.

In addition to improving pavement performance and durability, anti-stripping agents can also help to reduce environmental impact. By preventing pavement failure and the need for frequent repairs, these agents can help to conserve natural resources and reduce the carbon footprint of road construction and maintenance projects. This can lead to a more sustainable and environmentally friendly approach to infrastructure development.

Overall, the use of anti-stripping agents in bitumen offers a wide range of benefits, including improved pavement performance, increased durability, and reduced environmental impact. By strengthening the bond between the bitumen and the aggregate, these agents can help to ensure that pavements remain intact and durable, even in the face of heavy traffic and harsh weather conditions. As such, they are an essential component in the construction and maintenance of roads, highways, and other infrastructure projects.

How to Choose the Right Anti Stripping Agent for Bitumen Applications

Bitumen, also known as asphalt, is a crucial component in the construction industry. It is commonly used in road construction, roofing, and waterproofing applications due to its durability and flexibility. However, one common issue that arises with bitumen is stripping, which occurs when the bond between the bitumen and the aggregate is weakened, leading to premature pavement failure. To prevent this problem, anti-stripping agents are used to improve the adhesion between the bitumen and the aggregate.

Choosing the right anti-stripping agent for bitumen applications is essential to ensure the longevity and performance of the pavement. There are several factors to consider when selecting an anti-stripping agent, including the type of aggregate, the climate conditions, and the desired performance characteristics of the pavement.

One of the most important factors to consider when choosing an anti-stripping agent is the type of aggregate being used in the pavement. Different aggregates have different surface properties, which can affect the adhesion between the bitumen and the aggregate. For example, aggregates with high moisture content or clay content are more prone to stripping, so a stronger anti-stripping agent may be required. On the other hand, aggregates with a rough surface texture may require a different type of anti-stripping agent to ensure proper adhesion.

Climate conditions also play a significant role in the selection of an anti-stripping agent. In regions with high humidity or frequent rainfall, the risk of stripping is higher due to the presence of moisture on the aggregate surface. In such cases, an anti-stripping agent with excellent water resistance properties is essential to prevent stripping and maintain the integrity of the pavement.

The desired performance characteristics of the pavement also influence the choice of anti-stripping agent. For example, if the pavement is expected to experience heavy traffic loads or extreme temperature fluctuations, a high-performance anti-stripping agent with superior adhesion properties may be necessary to ensure the longevity of the pavement.

When selecting an anti-stripping agent for bitumen applications, it is essential to consider the compatibility of the agent with the bitumen. Some anti-stripping agents may not be compatible with certain types of bitumen, which can lead to reduced adhesion and pavement failure. It is crucial to consult with a bitumen expert or manufacturer to determine the compatibility of the anti-stripping agent with the bitumen being used.

In conclusion, choosing the right anti-stripping agent for bitumen applications is crucial to prevent premature pavement failure and ensure the longevity and performance of the pavement. Factors such as the type of aggregate, climate conditions, and desired performance characteristics of the pavement should be considered when selecting an anti-stripping agent. Consulting with a bitumen expert or manufacturer can help ensure the compatibility of the anti-stripping agent with the bitumen being used. By taking these factors into account, you can select an anti-stripping agent that will effectively improve the adhesion between the bitumen and the aggregate, resulting in a durable and long-lasting pavement.