Table of Contents

Benefits of Using Polymer Additives in Bitumen Pavement

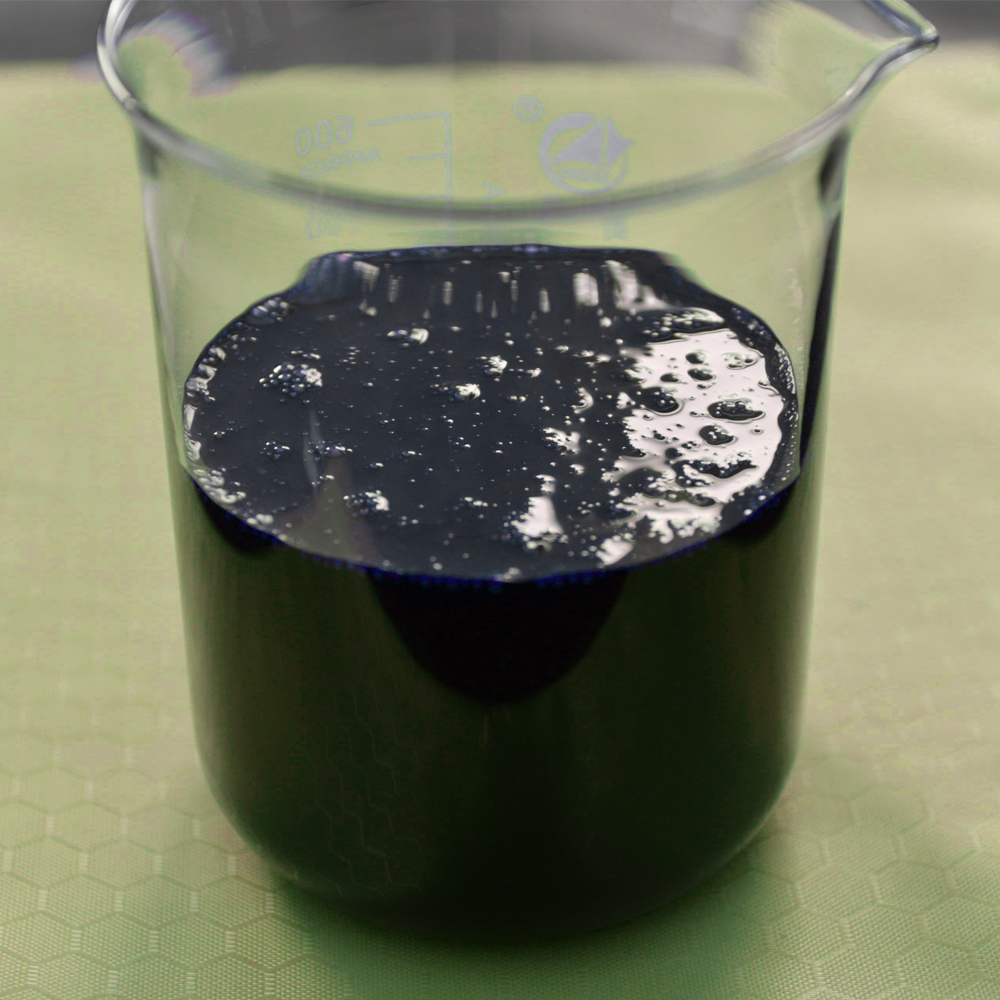

Bitumen, also known as asphalt, is a common material used in road construction due to its durability and ability to withstand heavy traffic. However, over time, bitumen can become brittle and prone to cracking, which can Lead to costly repairs and maintenance. To combat this issue, polymer additives are often used to enhance the performance and longevity of bitumen pavement.

Polymer additives are substances that are added to bitumen to improve its properties, such as flexibility, strength, and resistance to wear and tear. These additives can be synthetic or natural, and they work by forming a bond with the bitumen molecules, creating a stronger and more durable road surface.

One of the key benefits of using polymer additives in bitumen pavement is cost-effectiveness. While the initial cost of adding polymer additives to bitumen may be higher than using traditional bitumen alone, the long-term savings can be significant. By enhancing the durability of the road surface, polymer additives can reduce the need for frequent repairs and maintenance, saving money on labor and materials in the long run.

In addition to cost savings, polymer additives can also improve the overall performance of bitumen pavement. By increasing the flexibility and strength of the road surface, polymer additives can help prevent cracking and rutting, which can extend the lifespan of the pavement. This can result in smoother and safer driving conditions for motorists, as well as reduced noise Levels and improved fuel efficiency.

Furthermore, polymer additives can enhance the sustainability of bitumen pavement. By increasing the durability of the road surface, polymer additives can reduce the need for frequent resurfacing and reconstruction, which can help conserve natural resources and reduce carbon emissions associated with road construction. Additionally, some polymer additives are made from recycled materials, further reducing the environmental impact of road construction.

Overall, the benefits of using polymer additives in bitumen pavement are clear. Not only do they improve the durability and performance of the road surface, but they also offer cost savings, sustainability benefits, and a smoother driving experience for motorists. As road construction continues to evolve, polymer additives will likely play an increasingly important role in enhancing the longevity and sustainability of bitumen pavement.

In conclusion, polymer additives are a cost-effective and sustainable solution for improving the performance and longevity of bitumen pavement. By enhancing the durability and flexibility of the road surface, polymer additives can reduce the need for frequent repairs and maintenance, saving money and resources in the long run. As road construction technology continues to advance, polymer additives will remain a key component in creating safer, smoother, and more sustainable road surfaces for motorists around the world.

Cost-Effective Additives for Enhancing Durability of Bitumen Road Surfaces

Bitumen, also known as asphalt, is a commonly used material in road construction due to its durability and ability to withstand heavy traffic loads. However, over time, bitumen road surfaces can deteriorate due to factors such as weathering, traffic wear, and oxidation. To enhance the durability and longevity of bitumen road surfaces, additives can be incorporated into the mix during the construction process.

One of the key benefits of using additives in bitumen pavement is the cost-effectiveness they offer. By incorporating additives into the mix, the overall lifespan of the road surface can be extended, reducing the need for frequent maintenance and repairs. This can result in significant cost savings for road authorities and taxpayers in the long run.

There are several types of additives that can be used to enhance the performance of bitumen road surfaces. Polymer additives, for example, can improve the elasticity and flexibility of the pavement, making it more resistant to cracking and rutting. By increasing the durability of the road surface, polymer additives can help reduce maintenance costs and prolong the lifespan of the pavement.

| Serial Number | Name |

| 1 | Asphalt temperature modifiers |

Another cost-effective additive for bitumen road surfaces is crumb rubber. Crumb rubber is made from recycled tires and can be added to the bitumen mix to improve the resilience and skid resistance of the pavement. By incorporating crumb rubber into the mix, road authorities can not only enhance the performance of the pavement but also contribute to sustainability efforts by Recycling waste materials.

In addition to polymer and crumb rubber additives, rejuvenators can also be used to enhance the durability of bitumen road surfaces. Rejuvenators are typically added to aged bitumen to restore its properties and improve its performance. By rejuvenating the bitumen, road authorities can extend the lifespan of the pavement and reduce the need for costly repairs and replacements.

Furthermore, anti-stripping agents can be used as additives in bitumen pavement to improve the adhesion between the bitumen and the aggregate. By preventing moisture damage and stripping of the asphalt mix, anti-stripping agents can help maintain the integrity of the pavement and reduce the risk of premature failure.

Overall, the use of cost-effective additives in bitumen road surfaces can provide numerous benefits, including improved durability, reduced maintenance costs, and extended lifespan. By incorporating additives such as polymers, crumb rubber, rejuvenators, and anti-stripping agents into the mix, road authorities can enhance the performance of the pavement and ensure its long-term sustainability.

In conclusion, the use of additives in bitumen road surfaces is a cost-effective way to enhance durability and longevity. By incorporating additives such as polymers, crumb rubber, rejuvenators, and anti-stripping agents into the mix, road authorities can improve the performance of the pavement and reduce maintenance costs. With the increasing demand for sustainable and long-lasting road surfaces, the use of cost-effective additives in bitumen pavement is becoming increasingly important in the construction industry.