Table of Contents

Benefits of Using a Water Flow Meter 2 Inch for Industrial Applications

Water flow meters are essential tools for measuring the flow rate of water in various industrial applications. One of the most common sizes used in industrial settings is the 2-inch water flow meter. These meters are designed to accurately measure the flow of water in pipes with a 2-inch diameter, making them ideal for a wide range of industrial applications.

One of the key benefits of using a 2-inch water flow meter is its accuracy. These meters are designed to provide precise measurements of water flow, ensuring that industrial processes are running efficiently and effectively. With accurate flow measurements, businesses can optimize their operations and reduce waste, ultimately saving time and money in the long run.

In addition to accuracy, 2-inch water flow meters are also known for their durability and reliability. These meters are built to withstand the harsh conditions often found in industrial settings, such as high temperatures, pressure fluctuations, and exposure to Chemicals. This durability ensures that the meter will continue to provide accurate measurements over time, without the need for frequent maintenance or replacement.

Another benefit of using a 2-inch water flow meter is its versatility. These meters can be used in a wide range of industrial applications, from monitoring water usage in manufacturing processes to measuring flow rates in cooling systems. Their compact size and easy installation make them a convenient option for businesses looking to improve their water management practices.

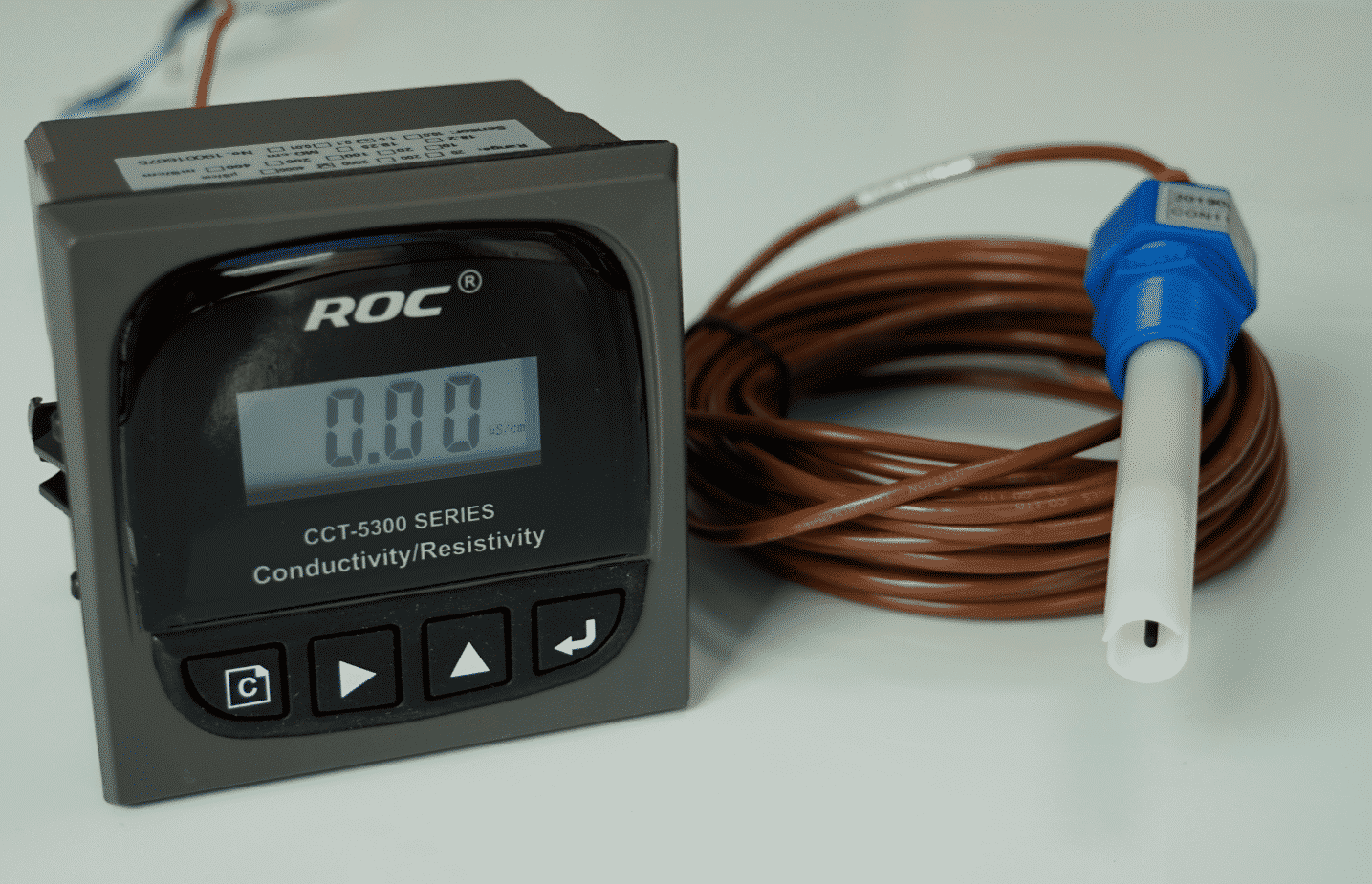

Furthermore, 2-inch water flow meters are often equipped with advanced features that enhance their functionality. For example, some meters come with digital displays that provide real-time data on flow rates, total water usage, and other important metrics. This information can help businesses make informed decisions about their water usage and identify areas where improvements can be made.

Additionally, many 2-inch water flow meters are designed to be energy-efficient, helping businesses reduce their overall energy consumption and lower their carbon footprint. By accurately measuring water flow and identifying areas of inefficiency, businesses can make adjustments to their operations that result in significant energy savings.

Overall, the benefits of using a 2-inch water flow meter for industrial applications are clear. From accuracy and reliability to versatility and advanced features, these meters offer businesses a cost-effective solution for monitoring and managing water flow. By investing in a high-quality water flow meter, businesses can improve their operations, reduce waste, and ultimately save money in the long run.

How to Choose the Right Water Flow Meter 2 Inch for Your Specific Needs

Water flow meters are essential tools for measuring the flow rate of water in various applications, from residential to industrial settings. When it comes to choosing the right water flow meter for your specific needs, there are several factors to consider. In this article, we will discuss the key considerations to keep in mind when selecting a water flow meter, specifically a 2-inch model.

One of the first things to consider when choosing a water flow meter is the flow rate that you need to measure. Flow meters are typically rated based on their maximum flow rate capacity, so it is important to select a meter that can handle the flow rate of your system. A 2-inch water flow meter is suitable for medium to high flow rates, making it ideal for applications such as irrigation systems, industrial processes, and large commercial buildings.

Another important factor to consider is the type of water flow meter that best suits your needs. There are several types of flow meters available, including electromagnetic, ultrasonic, turbine, and positive displacement meters. Each type has its own advantages and limitations, so it is important to choose the one that is most suitable for your specific application. For example, electromagnetic flow meters are ideal for measuring the flow of conductive liquids, while ultrasonic flow meters are suitable for non-invasive flow measurement.

Accuracy is another crucial factor to consider when selecting a water flow meter. The accuracy of a flow meter is typically expressed as a percentage of the actual flow rate, with higher accuracy meters providing more precise measurements. When choosing a 2-inch water flow meter, it is important to select a model with the level of accuracy required for your application. For most applications, a flow meter with an accuracy of +/- 1% is sufficient, but for more precise measurements, a meter with higher accuracy may be necessary.

In addition to accuracy, it is also important to consider the repeatability of a water flow meter. Repeatability refers to the ability of a flow meter to provide consistent measurements over time. A flow meter with good repeatability will produce the same results when measuring the same flow rate multiple times. When selecting a 2-inch water flow meter, be sure to choose a model with good repeatability to ensure reliable and consistent measurements.

| ROS-2210 Double-Stage Reverse Osmosis Program Controller | |

| \\u3000 | 1.water source water tank without water protection |

| \\u3000 | 2. Pure tank low level |

| \\u3000 | 3.Pure tank high level |

| Acquisition signal | 4.low pressure protection |

| \\u3000 | 5.high pressure protection |

| \\u3000 | 6.pretreatment regeneration |

| \\u3000 | 7.manual/automatic control |

| \\u3000 | 1.water inlet valve |

| \\u3000 | 2. flush valve |

| Output control | 3. low pressure pump |

| \\u3000 | 4.high pressure pump |

| \\u3000 | 5.conductivity over standard valve |

| Measuring range | 0~2000uS |

| Temperature range | Based on 25\\u2103, automatic temperature compensation |

| \\u3000 | AC220v\\u00b110% 50/60Hz |

| Power supply | AC110v\\u00b110% 50/60Hz |

| \\u3000 | DC24v\\u00b110% |

| Medium temperature | The normal temperature electrode<60\\u2103 |

| \\u3000 | High temperature electrode<120\\u2103 |

| Control output | 5A/250V AC |

| Relative humidity | \\u226485% |

| Ambient temperature | 0~50\\u2103 |

| Hole Size | 92*92mm(high*wide) |

| Installation method | The embedded |

| Cell constant | 1.0cm-\\u00b9*2 |

| Display usage | Digital display: conductivity value/temperature value; Supporting RO process flow chart |

| \\u3000 | 1.Electrode constant and type setting |

| \\u3000 | 2.Conductivity overrun setting |

| \\u3000 | 3.Flush Settings at intervals of * hours |

| Main function | 4.Flushing time setting |

| \\u3000 | 5.RO membrane running time setting |

| \\u3000 | 6.Power on automatic operation/stop setting |

| \\u3000 | 7.Mailing address, baud rate setting |

| \\u3000 | 8.Optional RS-485 communication interface |

Installation and maintenance requirements are also important considerations when choosing a water flow meter. Some flow meters require specialized installation procedures, while others are more straightforward to install. Similarly, some meters require regular calibration and maintenance to ensure accurate measurements, while others are more low-maintenance. When selecting a 2-inch water flow meter, consider the installation and maintenance requirements to ensure that it is suitable for your specific application and budget.

In conclusion, choosing the right water flow meter is essential for accurate and reliable flow rate measurement. When selecting a 2-inch water flow meter, consider factors such as flow rate, type, accuracy, repeatability, installation, and maintenance requirements to ensure that you choose a meter that meets your specific needs. By carefully considering these factors, you can select a water flow meter that provides accurate and reliable measurements for your application.