Table of Contents

Benefits of Using a Wire Rope Hanging System for Industrial Applications

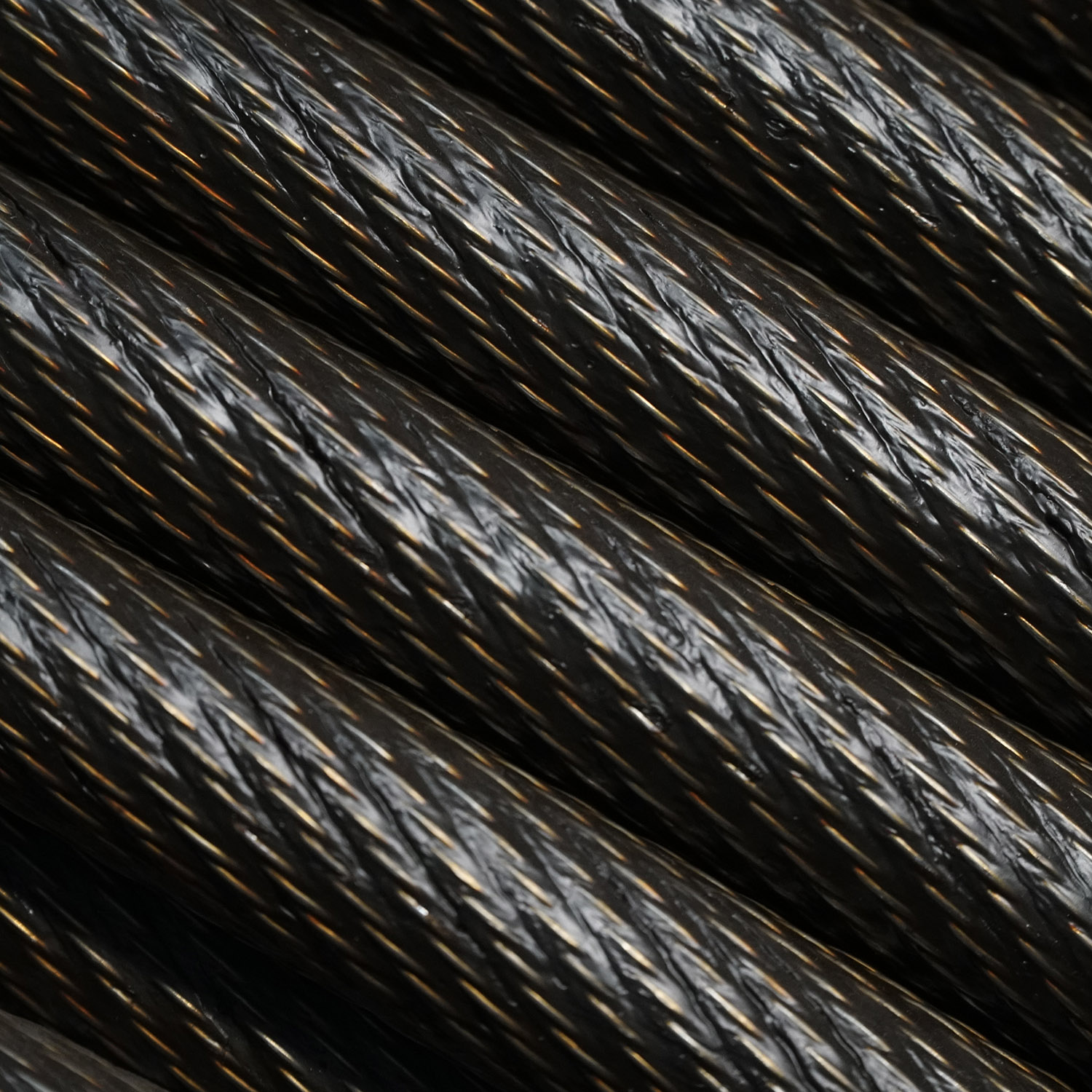

Wire rope hanging systems are a crucial component in many industrial applications, providing a reliable and durable method for suspending heavy loads. One popular option is the black coated wire rope, which offers additional protection against corrosion and wear. In this article, we will explore the benefits of using a wire rope hanging system, particularly the black coated variety, in industrial settings.

One of the primary advantages of a wire rope hanging system is its strength and durability. Wire ropes are constructed from multiple strands of steel wire twisted together to form a strong and flexible cable. This construction allows wire ropes to support heavy loads with ease, making them ideal for lifting and suspending equipment in industrial environments. The black coating on the wire rope provides an extra layer of protection against corrosion, extending the lifespan of the rope and ensuring its continued reliability.

In addition to their strength and durability, wire rope hanging systems are also highly versatile. They can be easily customized to suit the specific needs of a particular application, with various sizes and configurations available to accommodate different load capacities and installation requirements. This flexibility makes wire rope hanging systems a popular choice for a wide range of industrial applications, from construction and mining to manufacturing and transportation.

Another benefit of using a wire rope hanging system is its ease of installation and maintenance. Wire ropes are relatively simple to install, requiring only basic tools and equipment. Once in place, they require minimal maintenance to keep them in optimal working condition. The black coating on the wire rope helps to reduce friction and wear, further extending the maintenance intervals and reducing the need for frequent replacements.

Safety is a top priority in any industrial setting, and wire rope hanging systems are designed with safety in mind. The strength and reliability of wire ropes ensure that they can safely support heavy loads without the risk of failure. The black coating on the wire rope provides an additional layer of protection against wear and corrosion, reducing the likelihood of accidents or equipment damage. Regular inspections and maintenance can help to identify any potential issues before they become a safety hazard.

In conclusion, wire rope hanging systems, particularly the black coated variety, offer a range of benefits for industrial applications. Their strength, durability, versatility, ease of installation and maintenance, and safety features make them a popular choice for lifting and suspending heavy loads in a variety of settings. Whether used in construction, mining, manufacturing, or transportation, wire rope hanging systems provide a reliable and efficient solution for handling heavy equipment. Consider incorporating a wire rope hanging system into your industrial operations to improve safety, efficiency, and productivity.

How to Properly Maintain and Care for Black Coated Wire Rope in a Hanging System

Wire rope hanging systems are a popular choice for many applications due to their strength, durability, and versatility. When it comes to black coated wire rope, proper maintenance and care are essential to ensure its longevity and performance. In this article, we will discuss some important tips on how to properly maintain and care for black coated wire rope in a hanging system.

One of the most important aspects of maintaining black coated wire rope is regular inspection. Inspecting the wire rope regularly can help identify any signs of wear or damage before they become a more serious issue. Look for any signs of fraying, kinks, or corrosion on the wire rope. If any of these issues are present, it is important to address them promptly to prevent further damage.

In addition to regular inspections, it is also important to clean black coated wire rope regularly. Dirt, debris, and other contaminants can accumulate on the wire rope over time, leading to increased wear and corrosion. To clean the wire rope, simply use a mild detergent and water solution to remove any dirt or grime. Be sure to rinse the wire rope thoroughly and allow it to dry completely before reusing it.

Another important aspect of maintaining black coated wire rope is lubrication. Lubricating the wire rope can help reduce friction and wear, extending its lifespan. When lubricating the wire rope, be sure to use a lubricant that is specifically designed for use on wire rope. Apply the lubricant evenly along the length of the wire rope, making sure to cover all surfaces. It is recommended to lubricate the wire rope regularly to ensure optimal performance.

In addition to regular maintenance, it is also important to store black coated wire rope properly when not in use. Store the wire rope in a dry, cool, and well-ventilated area to prevent moisture buildup and corrosion. Avoid storing the wire rope in direct sunlight or near sources of heat, as this can cause the coating to degrade over time. Proper storage can help prolong the life of the wire rope and ensure its performance when needed.

When using black coated wire rope in a hanging system, it is important to follow the manufacturer’s guidelines and recommendations. Ensure that the wire rope is properly installed and secured to prevent accidents or injuries. Avoid overloading the wire rope beyond its recommended capacity, as this can Lead to premature wear and failure. Regularly inspect the wire rope for any signs of wear or damage, and address any issues promptly.

In conclusion, proper maintenance and care are essential for ensuring the longevity and performance of black coated wire rope in a hanging system. By following these tips and guidelines, you can help prolong the life of your wire rope and ensure its safe and reliable operation. Regular inspections, cleaning, lubrication, and proper storage are key aspects of maintaining black coated wire rope. Remember to always follow the manufacturer’s recommendations and guidelines when using wire rope in a hanging system.