目录

Advantages of Using API 16 Seamless Casing Pipe in Oil and Gas Industry

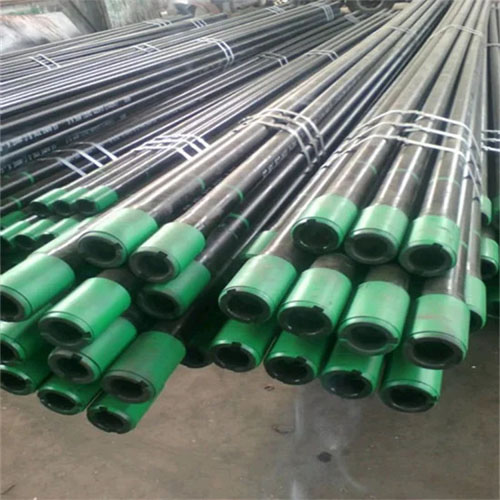

API 16″ seamless casing pipe is a crucial component in the oil and gas industry. It is used to protect and support the wellbore during drilling and completion operations. This type of casing pipe is manufactured according to the American Petroleum Institute (API) standards, ensuring high quality and reliability. There are several advantages to using API 16″ seamless casing pipe in the oil and gas industry.

One of the main advantages of API 16″ seamless casing pipe is its strength and durability. This type of casing pipe is made from high-quality steel that can withstand high pressure and extreme temperatures. It is designed to provide a strong and reliable barrier between the wellbore and the surrounding rock formations. This helps to prevent any leaks or blowouts that could result in environmental damage or Safety hazards.

Another advantage of API 16″ seamless casing pipe is its resistance to corrosion. The harsh conditions in the oil and gas industry can cause metal pipes to corrode over time. However, seamless casing pipe is manufactured using a special process that eliminates the need for welding, which can weaken the pipe and make it more susceptible to corrosion. This ensures that the casing pipe will last longer and require less maintenance over its lifetime.

API 16″ seamless casing pipe also offers superior performance in terms of pressure containment. The seamless design of the pipe eliminates weak points that are common in welded pipes, making it more resistant to leaks and failures. This is crucial in the oil and gas industry, where any loss of containment can result in costly downtime and environmental damage. By using API 16″ seamless casing pipe, companies can ensure that their operations run smoothly and safely.

In addition to its strength and durability, API 16″ seamless casing pipe is also highly versatile. It can be used in a variety of applications, including drilling, completion, and production. This makes it a cost-effective solution for companies in the oil and gas industry, as they can use the same type of casing pipe for multiple purposes. This reduces the need for multiple types of casing pipe, saving time and money in the long run.

Overall, API 16″ seamless casing pipe offers numerous advantages for companies in the oil and gas industry. Its strength, durability, resistance to corrosion, and superior performance make it an ideal choice for protecting and supporting wellbores during drilling and completion operations. By using API 16″ seamless casing pipe, companies can ensure the safety and efficiency of their operations while reducing maintenance costs and downtime. It is clear that API 16″ seamless casing pipe is a valuable asset for any company operating in the oil and gas industry.

How to Properly Install and Maintain API 16 Seamless Casing Pipe for Maximum Efficiency

API 16″ seamless casing pipe is a critical component in oil and gas drilling operations. It is designed to provide structural support to the wellbore and protect the drilling equipment from external elements. Proper installation and maintenance of API 16″ seamless casing pipe are essential to ensure maximum efficiency and longevity of the equipment.

When installing API 16″ seamless casing pipe, it is important to follow the manufacturer’s guidelines and recommendations. The pipe should be handled with care to prevent any damage during transportation and installation. Before installing the casing pipe, it is crucial to inspect it for any defects or imperfections that could compromise its integrity.

Once the casing pipe has been inspected and deemed suitable for installation, it should be carefully lowered into the wellbore using a casing Elevator or other appropriate equipment. The pipe should be lowered slowly and steadily to prevent any sudden movements that could cause damage to the pipe or the wellbore.

After the casing pipe has been installed, it should be properly cemented in place to provide additional support and seal off any potential leaks. The cementing process should be done according to industry standards and best practices to ensure a secure and reliable seal.

Proper maintenance of API 16″ seamless casing pipe is essential to ensure its longevity and efficiency. Regular inspections should be conducted to check for any signs of wear or damage. Any defects or imperfections should be addressed promptly to prevent further deterioration of the pipe.

In addition to regular inspections, the casing pipe should be cleaned and maintained regularly to prevent the buildup of debris or corrosion. Cleaning the pipe can help prevent blockages and ensure smooth flow of fluids through the wellbore.

It is also important to monitor the pressure and temperature of the casing pipe during operation to ensure that it is functioning properly. Any abnormal readings should be investigated immediately to prevent potential damage to the equipment.

In the event of a leak or other issue with the casing pipe, it is important to take immediate action to prevent any further damage. Depending on the severity of the issue, repairs may need to be made to the casing pipe or it may need to be replaced entirely.

Proper installation and maintenance of API 16″ seamless casing pipe are essential to ensure the efficiency and longevity of the equipment. By following industry best practices and guidelines, operators can maximize the performance of their casing pipe and minimize the risk of costly repairs or downtime.

In conclusion, API 16″ seamless casing pipe is a critical component in oil and gas drilling operations. Proper installation and maintenance of the casing pipe are essential to ensure its efficiency and longevity. By following industry best practices and guidelines, operators can maximize the performance of their casing pipe and minimize the risk of costly repairs or downtime.