目录

Benefits of Using Bitumen High Viscosity Additive Gelling Agent in Asphalt Mixtures

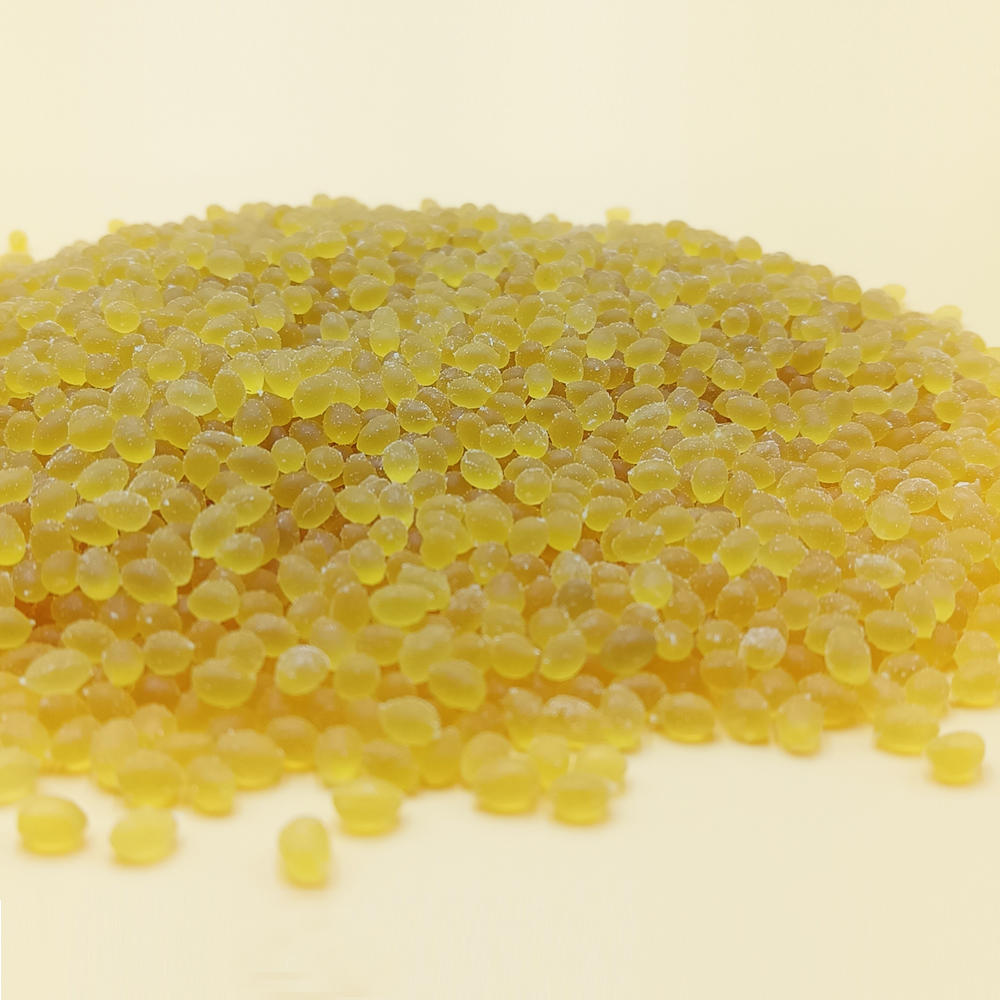

Bitumen high viscosity additive gelling agents are becoming increasingly popular in the construction industry for their ability to improve the performance of asphalt mixtures. These additives are designed to increase the viscosity of bitumen, which in turn enhances the overall quality and durability of asphalt pavements. In this article, we will explore the benefits of using bitumen high viscosity additive gelling agents in asphalt mixtures.

One of the key advantages of using bitumen high viscosity additive gelling agents is their ability to improve the workability of asphalt mixtures. By increasing the viscosity of bitumen, these additives make it easier to handle and transport the asphalt mixture during the construction process. This results in a more uniform and consistent application of the asphalt, leading to a smoother and more durable pavement surface.

In addition to improving workability, bitumen high viscosity additive gelling agents also help to enhance the performance of asphalt pavements. These additives increase the stiffness and resistance of the asphalt mixture, making it more resistant to rutting, cracking, and other forms of distress. This results in a longer service life for the pavement, reducing the need for costly repairs and maintenance in the future.

Another benefit of using bitumen high viscosity additive gelling agents is their ability to improve the overall sustainability of asphalt pavements. By enhancing the performance and durability of the asphalt mixture, these additives help to extend the service life of the pavement, reducing the need for frequent resurfacing and reconstruction. This not only saves time and money but also reduces the environmental impact of asphalt production and construction.

Furthermore, bitumen high viscosity additive gelling agents can also help to reduce the overall cost of asphalt pavements. By improving the performance and durability of the asphalt mixture, these additives can help to extend the service life of the pavement, reducing the need for frequent repairs and maintenance. This results in long-term cost savings for both contractors and government agencies responsible for maintaining the infrastructure.

Overall, the benefits of using bitumen high viscosity additive gelling agents in asphalt mixtures are clear. These additives improve workability, enhance performance, increase sustainability, and reduce costs, making them an attractive option for contractors and engineers looking to improve the quality and durability of asphalt pavements. By incorporating these additives into asphalt mixtures, construction professionals can create smoother, more durable, and longer-lasting pavement surfaces that meet the demands of today’s infrastructure needs.

| Serial Number | Commodity Name |

| 1 | asphalt bonding agent |

In conclusion, bitumen high viscosity additive gelling agents are a valuable tool for improving the performance and durability of asphalt pavements. These additives offer a range of benefits, including improved workability, enhanced performance, increased sustainability, and reduced costs. By incorporating these additives into asphalt mixtures, construction professionals can create high-quality pavement surfaces that meet the demands of today’s infrastructure needs.

How to Properly Incorporate Bitumen High Viscosity Additive Gelling Agent in Asphalt Production Process

Bitumen high viscosity additive gelling agents play a crucial role in the production of asphalt. These additives help improve the performance and durability of asphalt pavements by enhancing their resistance to rutting, cracking, and aging. Properly incorporating bitumen high viscosity additive gelling agents in the asphalt production process is essential to ensure the desired properties and performance of the final product.

One of the key steps in incorporating bitumen high viscosity additive gelling agents in the asphalt production process is selecting the right type of additive for the specific application. There are various types of gelling agents available in the market, each with its own set of properties and characteristics. It is important to choose an additive that is compatible with the base bitumen and can effectively enhance its viscosity and performance.

Once the appropriate gelling agent has been selected, the next step is to determine the optimal dosage for the desired performance. The dosage of the gelling agent will depend on factors such as the type of base bitumen, the desired viscosity level, and the environmental conditions in which the asphalt will be used. It is important to carefully follow the manufacturer’s recommendations and conduct thorough testing to determine the optimal dosage for the specific application.

Incorporating bitumen high viscosity additive gelling agents in the asphalt production process requires careful mixing and blending to ensure uniform distribution of the additive throughout the asphalt mixture. The gelling agent should be added to the base bitumen at the appropriate temperature and mixed thoroughly to achieve a homogenous blend. Proper mixing is essential to ensure that the gelling agent is evenly dispersed in the asphalt mixture and can effectively enhance its viscosity and performance.

After the gelling agent has been properly incorporated into the asphalt mixture, it is important to monitor the viscosity and performance of the final product to ensure that the desired properties have been achieved. Testing the viscosity of the asphalt mixture at various stages of production can help identify any issues or inconsistencies in the mixing process and make necessary adjustments to optimize the performance of the final product.

In conclusion, incorporating bitumen high viscosity additive gelling agents in the asphalt production process is essential to enhance the performance and durability of asphalt pavements. Selecting the right type of additive, determining the optimal dosage, and properly mixing and blending the additive are key steps in ensuring the desired properties and performance of the final product. By following these guidelines and conducting thorough testing, asphalt producers can effectively incorporate gelling agents into their production process and produce high-quality asphalt pavements that meet the requirements of their specific applications.