目录

Advantages of Dry Type Transformers in Industrial Applications

Transformers are essential components in electrical systems, as they help to regulate voltage Levels and ensure the efficient transmission of electricity. When it comes to industrial applications, choosing the right type of transformer is crucial to ensure the smooth operation of equipment and machinery. Two common types of transformers used in industrial settings are dry type transformers and oil-immersed transformers.

Dry type transformers, as the name suggests, do not use oil as a cooling medium. Instead, they rely on air to dissipate heat generated during operation. This makes them a popular choice for indoor applications where the use of oil may pose a Safety hazard. Dry type transformers are also more environmentally friendly, as they do not require the use of oil, which can be harmful if leaked or spilled.

| Type | Rated capacity (KVA) | Voltage combination(KV) | Off-load losses(W) | Load losses(W) | Off-load Current (%) | Short-circuit impedance (%) |

| SH15-M-30 | 30 | 6,6.3,10,10.5,11/0.4 | 33 | 630 | 1.50 | 4.0 |

| SH15-M-50 | 50 | 6,6.3,10,10.5,11/0.4 | 43 | 910 | 1.20 | 4.0 |

| SH15-M-63 | 63 | 6,6.3,10,10.5,11/0.4 | 50 | 1090 | 1.10 | 4.0 |

| SH15-M-80 | 80 | 6,6.3,10,10.5,11/0.4 | 60 | 1310 | 1.00 | 4.0 |

| SH15-M-100 | 100 | 6,6.3,10,10.5,11/0.4 | 75 | 1580 | 0.90 | 4.0 |

| SH15-M-125 | 125 | 6,6.3,10,10.5,11/0.4 | 85 | 1890 | 0.80 | 4.0 |

| SH15-M-160 | 160 | 6,6.3,10,10.5,11/0.4 | 100 | 2310 | 0.60 | 4.0 |

| SH15-M-200 | 200 | 6,6.3,10,10.5,11/0.4 | 120 | 2730 | 0.60 | 4.0 |

| SH15-M-250 | 250 | 6,6.3,10,10.5,11/0.4 | 140 | 3200 | 0.60 | 4.0 |

| SH15-M-315 | 315 | 6,6.3,10,10.5,11/0.4 | 170 | 3830 | 0.50 | 4.0 |

| SH15-M-400 | 400 | 6,6.3,10,10.5,11/0.4 | 200 | 4520 | 0.50 | 4.0 |

| SH15-M-500 | 500 | 6,6.3,10,10.5,11/0.4 | 240 | 5140 | 0.50 | 4.0 |

| SH15-M-630 | 630 | 6,6.3,10,10.5,11/0.4 | 320 | 6200 | 0.30 | 4.5 |

| SH15-M-800 | 800 | 6,6.3,10,10.5,11/0.4 | 380 | 7500 | 0.30 | 4.5 |

| SH15-M-1000 | 1000 | 6,6.3,10,10.5,11/0.4 | 450 | 10300 | 0.30 | 4.5 |

| SH15-M-1250 | 1250 | 6,6.3,10,10.5,11/0.4 | 530 | 12000 | 0.20 | 4.5 |

| SH15-M-1600 | 1600 | 6,6.3,10,10.5,11/0.4 | 630 | 14500 | 0.20 | 4.5 |

| SH15-M-2000 | 2000 | 6,6.3,10,10.5,11/0.4 | 750 | 18300 | 0.20 | 5.0 |

| SH15-M-2500 | 2500 | 6,6.3,10,10.5,11/0.4 | 900 | 21200 | 0.20 | 5.0 |

One of the key advantages of dry type transformers is their low maintenance requirements. Since they do not use oil, there is no need for regular oil testing and replacement, which can be time-consuming and costly. This makes dry type transformers a cost-effective option for industrial applications where downtime must be minimized.

In addition to their low maintenance requirements, dry type transformers are also known for their durability and reliability. They are less prone to failure compared to oil-immersed transformers, as there is no risk of oil leakage or contamination. This makes them a popular choice for critical industrial applications where uninterrupted power supply is essential.

Another advantage of dry type transformers is their compact size and lightweight design. This makes them easy to install and transport, making them ideal for applications where space is limited. In addition, dry type transformers are also quieter compared to oil-immersed transformers, making them suitable for noise-sensitive environments.

When it comes to choosing a supplier for dry type transformers, China is a leading manufacturer of high-quality transformers. Chinese companies are known for their expertise in transformer manufacturing and their commitment to providing the best service to their customers. Many Chinese companies offer competitive prices, fast delivery times, and excellent after-sales support, making them a popular choice for industrial customers worldwide.

In addition to their high-quality products and excellent service, Chinese transformer manufacturers also offer generous warranties on their products. This provides customers with peace of mind knowing that their investment is protected in case of any defects or malfunctions. Many Chinese companies also provide technical support and training to help customers get the most out of their transformers.

To learn more about the advantages of dry type transformers and how they can benefit your industrial applications, many Chinese companies offer informative videos on their websites. These videos provide valuable insights into the design, construction, and operation of dry type transformers, helping customers make informed decisions when choosing a transformer for their specific needs.

In conclusion, dry type transformers offer several advantages in industrial applications, including low maintenance requirements, durability, reliability, compact size, and lightweight design. Chinese companies are a trusted source for high-quality dry type transformers, offering the best service, generous warranties, and informative videos to help customers make informed decisions. Consider choosing a dry type transformer from a reputable Chinese company for your industrial applications to ensure reliable and efficient power distribution.

How to Choose the Right Oil Immersed Transformer for Your Power Distribution Needs

When it comes to power distribution, transformers play a crucial role in ensuring that electricity is efficiently and safely delivered to homes, businesses, and industries. One of the key decisions that needs to be made when selecting a transformer is whether to choose a dry type or oil immersed transformer. Both types have their own advantages and disadvantages, and understanding the differences between them is essential in making the right choice for your specific power distribution needs.

Dry type transformers are typically used in indoor applications where fire safety is a concern. These transformers do not require any Cooling Oil, making them a safer option for indoor installations. They are also more environmentally friendly as they do not pose the risk of oil leaks or spills. However, dry type transformers are generally more expensive than oil immersed transformers and have a lower power rating.

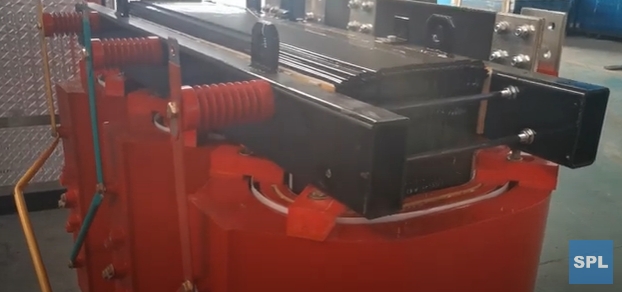

On the other hand, oil immersed transformers are commonly used in outdoor applications where fire safety is less of a concern. These transformers are filled with insulating oil that helps to dissipate heat and keep the transformer cool during operation. Oil immersed transformers are generally more cost-effective than dry type transformers and have a higher power rating. However, they require regular maintenance to ensure that the oil is clean and free of contaminants.

https://www.youtube.com/watch?v=-G3wD7ept4IWhen choosing between a dry type and oil immersed transformer, it is important to consider factors such as the installation location, power requirements, and maintenance needs. If fire safety is a top priority and the transformer will be installed indoors, a dry type transformer may be the best option. On the other hand, if cost-effectiveness and higher power ratings are more important, an oil immersed transformer may be the better choice.

In addition to selecting the right type of transformer, it is also important to choose a reputable manufacturer that offers high-quality products and reliable service. One such company that stands out in the transformer industry is China company. With years of experience in designing and manufacturing transformers, China company has built a reputation for delivering top-notch products that meet the highest standards of quality and performance.

China company offers a wide range of transformers, including 3 phase transformers that are designed to meet the specific power distribution needs of customers. Whether you need a transformer for residential, commercial, or industrial applications, China company has a solution that will meet your requirements. In addition to high-quality products, China company also provides excellent customer service, including warranty coverage and technical support.

To help customers make informed decisions about their transformer needs, China company offers a variety of resources, including informative videos that explain the different types of transformers available and how to choose the right one for your specific application. These videos provide valuable insights into the features and benefits of each type of transformer, helping customers make educated decisions that will meet their power distribution needs.

In conclusion, choosing the right transformer for your power distribution needs is a critical decision that requires careful consideration of factors such as installation location, power requirements, and maintenance needs. Whether you opt for a dry type or oil immersed transformer, selecting a reputable manufacturer like China company will ensure that you receive a high-quality product that meets your specific requirements. With excellent customer service, warranty coverage, and informative resources like videos, China company is a trusted partner in the transformer industry that will help you make the right choice for your power distribution needs.

| model | Rated power (KVA) | Voltage combination(KV) | No-load losses(W) | Load losses(W) | No-load current (%) | Short-circuit impedance (%) |

| SC13-30 | 30 | 6,6.3,6.6,10,11/0.4 | 150 | 710 | 2.3 | 4.0 |

| SC13-50 | 50 | 6,6.3,6.6,10,11/0.4 | 215 | 1000 | 2.2 | 4.0 |

| SC13-80 | 80 | 6,6.3,6.6,10,11/0.4 | 295 | 1380 | 1.7 | 4.0 |

| SC13-100 | 100 | 6,6.3,6.6,10,11/0.4 | 320 | 1570 | 1.7 | 4.0 |

| SC13-125 | 125 | 6,6.3,6.6,10,11/0.4 | 375 | 1850 | 1.5 | 4.0 |

| SCB13-160 | 160 | 6,6.3,6.6,10,11/0.4 | 430 | 2130 | 1.5 | 4.0 |

| SCB13-200 | 200 | 6,6.3,6.6,10,11/0.4 | 495 | 2530 | 1.3 | 4.0 |

| SCB13-250 | 250 | 6,6.3,6.6,10,11/0.4 | 575 | 2760 | 1.3 | 4.0 |

| SCB13-315 | 315 | 6,6.3,6.6,10,11/0.4 | 705 | 3470 | 1.1 | 4.0 |

| SCB13-400 | 400 | 6,6.3,6.6,10,11/0.4 | 785 | 3990 | 1.1 | 4.0 |

| SCB13-500 | 500 | 6,6.3,6.6,10,11/0.4 | 930 | 4880 | 1.1 | 4.0 |

| SCB13-630 | 630 | 6,6.3,6.6,10,11/0.4 | 1070 | 5880 | 0.9 | 4.0 |

| SCB13-630 | 630 | 6,6.3,6.6,10,11/0.4 | 1040 | 5960 | 0.9 | 6.0 |

| SCB13-800 | 800 | 6,6.3,6.6,10,11/0.4 | 1210 | 6960 | 0.9 | 6.0 |

| SCB13-1000 | 1000 | 6,6.3,6.6,10,11/0.4 | 1410 | 8130 | 0.9 | 6.0 |

| SCB13-1250 | 1250 | 6,6.3,6.6,10,11/0.4 | 1670 | 9690 | 0.9 | 6.0 |

| SCB13-1600 | 1600 | 6,6.3,6.6,10,11/0.4 | 1960 | 11700 | 0.9 | 6.0 |

| SCB13-2000 | 2000 | 6,6.3,6.6,10,11/0.4 | 2440 | 14400 | 0.7 | 6.0 |

| SCB13-2500 | 2500 | 6,6.3,6.6,10,11/0.4 | 2880 | 17100 | 0.7 | 6.0 |