Table of Contents

Benefits of Using 4 1/2 12.75 EUE Grade P110 Casing Pipe for Oil Well Operations

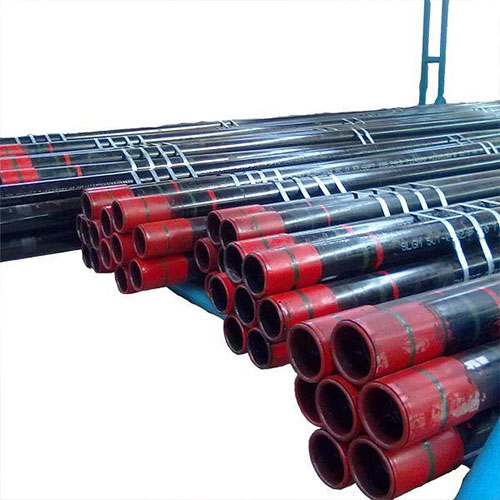

Oil well operations require high-quality equipment to ensure efficiency and Safety. One crucial component in these operations is the casing pipe, which plays a vital role in protecting the wellbore and ensuring the integrity of the well. One popular choice for casing pipe is the 4 1/2″ 12.75 EUE Grade P110 casing pipe. This article will discuss the benefits of using this specific type of casing pipe for oil well operations.

The 4 1/2″ 12.75 EUE Grade P110 casing pipe is known for its durability and strength. Made from high-quality materials, this casing pipe is designed to withstand the harsh conditions of oil well operations. Its Grade P110 designation indicates that it has a minimum yield strength of 110,000 psi, making it suitable for high-pressure environments. This level of strength and durability ensures that the casing pipe can effectively support the weight of the wellbore and withstand the forces exerted during drilling and production.

In addition to its strength, the 4 1/2″ 12.75 EUE Grade P110 casing pipe is also highly resistant to corrosion. Corrosion is a common issue in oil well operations, as the presence of corrosive substances in the wellbore can degrade the casing pipe over time. However, the Grade P110 casing pipe is specifically designed to resist corrosion, ensuring that it maintains its integrity and longevity throughout its service life. This corrosion resistance is essential for protecting the wellbore and preventing leaks or failures that could result in costly downtime and environmental damage.

Another benefit of using the 4 1/2″ 12.75 EUE Grade P110 casing pipe is its ease of installation. The EUE (External Upset End) connection design allows for quick and efficient installation, reducing downtime and labor costs. This connection design also provides a tight seal that prevents leaks and ensures the integrity of the wellbore. Additionally, the 4 1/2″ size of the casing pipe is versatile and can be used in a wide range of wellbore diameters, making it a flexible and cost-effective choice for oil well operations.

Furthermore, the 4 1/2″ 12.75 EUE Grade P110 casing pipe is compliant with industry standards and regulations. This ensures that the casing pipe meets the necessary requirements for safety and performance in oil well operations. By using a casing pipe that is certified to industry standards, operators can have confidence in the reliability and quality of their equipment, reducing the risk of accidents or failures during drilling and production.

In conclusion, the 4 1/2″ 12.75 EUE Grade P110 casing pipe offers numerous benefits for oil well operations. Its strength, corrosion resistance, ease of installation, and compliance with industry standards make it a reliable and efficient choice for protecting the wellbore and ensuring the success of drilling and production activities. By investing in high-quality casing pipe like the 4 1/2″ 12.75 EUE Grade P110, operators can improve the safety, efficiency, and longevity of their oil well operations.

Maintenance Tips for Extending the Lifespan of 4 1/2 12.75 EUE Grade P110 Casing Pipe in Oil Well Applications

When it comes to oil well applications, the 4 1/2″ 12.75 EUE Grade P110 casing pipe is a crucial component that plays a significant role in the extraction of oil and gas. This type of casing pipe is designed to withstand high pressure and harsh conditions, making it essential for maintaining the integrity of the well. To ensure the longevity and efficiency of the casing pipe, proper maintenance is key.

One of the most important maintenance tips for extending the lifespan of the 4 1/2″ 12.75 EUE Grade P110 casing pipe is regular inspection. Inspecting the casing pipe on a routine basis allows for early detection of any potential issues such as corrosion, leaks, or damage. By identifying problems early on, you can prevent further damage and avoid costly repairs or replacements.

In addition to regular inspections, it is essential to clean the casing pipe regularly to remove any buildup of debris, sediment, or other contaminants. This buildup can Lead to corrosion and deterioration of the pipe, compromising its integrity and effectiveness. Cleaning the casing pipe can be done using specialized tools and equipment designed for this purpose.

Another important maintenance tip for extending the lifespan of the 4 1/2″ 12.75 EUE Grade P110 casing pipe is proper handling and storage. When handling the casing pipe, it is crucial to avoid dropping or mishandling it, as this can cause damage to the pipe. Additionally, storing the casing pipe in a dry and well-ventilated area can help prevent corrosion and deterioration.

Furthermore, it is essential to protect the casing pipe from extreme temperatures and environmental conditions. Exposure to extreme heat or cold can cause the casing pipe to expand or contract, leading to potential damage. By protecting the casing pipe from these conditions, you can help maintain its integrity and prolong its lifespan.

Lastly, it is important to follow the manufacturer’s guidelines and recommendations for the maintenance of the 4 1/2″ 12.75 EUE Grade P110 casing pipe. These guidelines are designed to ensure the proper care and maintenance of the casing pipe, helping to maximize its lifespan and efficiency. By following these recommendations, you can help prevent premature wear and damage to the casing pipe.

In conclusion, proper maintenance is essential for extending the lifespan of the 4 1/2″ 12.75 EUE Grade P110 casing pipe in oil well applications. Regular inspections, cleaning, proper handling and storage, protection from extreme conditions, and following manufacturer’s guidelines are all key components of effective maintenance. By taking these steps, you can help ensure the longevity and efficiency of the casing pipe, ultimately leading to a more productive and successful oil well operation.