Table of Contents

Benefits of Using Industrial Hydraulic Oil Pressure Stainless Filter Element 923944.0053

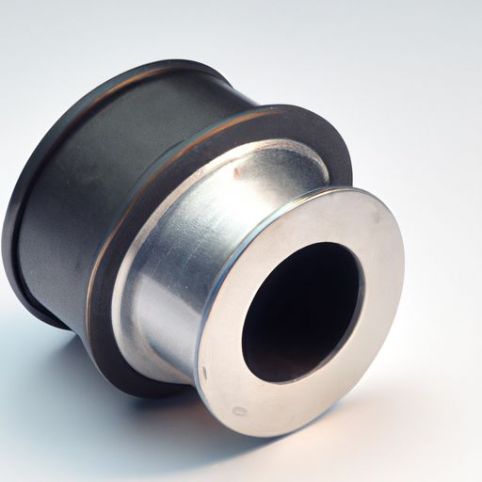

Industrial hydraulic systems are essential components in various industries, providing the power needed to operate heavy machinery and equipment. To ensure the smooth and efficient operation of these systems, it is crucial to maintain the cleanliness of the hydraulic oil that circulates through them. One way to achieve this is by using a high-quality filter element, such as the 923944.0053 industrial hydraulic oil pressure stainless filter element.

Industrial hydraulic systems are essential components in various industries, providing the power needed to operate heavy machinery and equipment. To ensure the smooth and efficient operation of these systems, it is crucial to maintain the cleanliness of the hydraulic oil that circulates through them. One way to achieve this is by using a high-quality filter element, such as the 923944.0053 industrial hydraulic oil pressure stainless filter element.

The 923944.0053 filter element is designed to remove contaminants from hydraulic oil, such as dirt, debris, and other particles that can cause damage to the system. By effectively filtering out these impurities, the filter element helps to prolong the life of the hydraulic system and reduce the risk of costly breakdowns and repairs.

One of the key benefits of using the 923944.0053 filter element is its high filtration efficiency. With a filtration rating of 5 microns, this filter element is capable of capturing even the smallest particles that can contaminate hydraulic oil. This ensures that the oil remains clean and free from impurities, allowing the hydraulic system to operate at peak performance.

In addition to its high filtration efficiency, the 923944.0053 filter element is also highly durable and reliable. Made from high-quality Stainless Steel, this filter element is designed to withstand the harsh operating conditions of industrial hydraulic systems. Its robust construction ensures that it can effectively filter oil for an extended period without losing its effectiveness.

Another advantage of the 923944.0053 filter element is its easy installation and maintenance. With its simple design and user-friendly features, this filter element can be quickly and easily installed in a hydraulic system. Additionally, it is easy to clean and replace when necessary, allowing for minimal downtime and maximum efficiency.

By using the 923944.0053 filter element in industrial hydraulic systems, businesses can benefit from improved system performance, reduced maintenance costs, and increased equipment lifespan. With clean and properly filtered oil circulating through the system, the risk of component wear and damage is significantly reduced, leading to fewer breakdowns and repairs.

Furthermore, the use of the 923944.0053 filter element can also help to improve the overall efficiency of the hydraulic system. By maintaining clean oil, the system can operate more smoothly and effectively, resulting in increased productivity and reduced energy consumption.

Overall, the 923944.0053 industrial hydraulic oil pressure stainless filter element offers a range of benefits for businesses looking to optimize the performance and longevity of their hydraulic systems. With its high filtration efficiency, durability, and ease of maintenance, this filter element is a cost-effective solution for ensuring the cleanliness and efficiency of industrial hydraulic systems. By investing in quality filtration products like the 923944.0053 filter element, businesses can protect their equipment, reduce downtime, and improve overall operational efficiency.

How to Properly Maintain and Replace Industrial Hydraulic Oil Pressure Stainless Filter Element 9239440053

Industrial hydraulic systems are essential components in many manufacturing and industrial processes. These systems rely on hydraulic oil to operate efficiently and effectively. One crucial part of maintaining a hydraulic system is ensuring that the hydraulic oil is clean and free of contaminants. This is where the industrial hydraulic oil pressure stainless filter element 9239440053 comes into play.

The 9239440053 filter element is designed to remove impurities and contaminants from hydraulic oil, ensuring that the system operates smoothly and efficiently. Regular maintenance and replacement of this filter element are essential to prevent damage to the hydraulic system and ensure its longevity.

To properly maintain and replace the industrial hydraulic oil pressure stainless filter element 9239440053, it is important to follow a few key steps. First and foremost, it is crucial to regularly inspect the filter element for any signs of wear or damage. This can include tears, holes, or Clogs that may impede the flow of hydraulic oil through the filter.

If any damage is found during inspection, it is important to replace the filter element immediately. Failure to do so can result in contaminants entering the hydraulic system, causing damage to the system components and reducing its overall efficiency.

When replacing the filter element, it is important to use a high-quality replacement element that meets the specifications of the original filter. Using a substandard or incompatible filter element can Lead to poor filtration and potential damage to the hydraulic system.

It is also important to follow the manufacturer’s guidelines for replacing the filter element. This may include specific instructions on how to remove and install the filter element, as well as recommendations for the frequency of replacement.

In addition to regular maintenance and replacement of the filter element, it is also important to monitor the hydraulic system for any signs of contamination. This can include unusual noises, leaks, or a decrease in system performance. If any of these signs are present, it is important to inspect the filter element and replace it if necessary.

Proper maintenance and replacement of the industrial hydraulic oil pressure stainless filter element 9239440053 are essential to ensuring the longevity and efficiency of a hydraulic system. By following these key steps and monitoring the system for any signs of contamination, industrial operators can prevent damage to the system and ensure its continued operation.

In conclusion, the industrial hydraulic oil pressure stainless filter element 9239440053 plays a crucial role in maintaining the efficiency and longevity of hydraulic systems. By following the proper maintenance and replacement procedures outlined in this article, industrial operators can ensure that their hydraulic systems operate smoothly and effectively. Regular inspection, timely replacement, and monitoring for signs of contamination are key steps in maintaining a healthy hydraulic system.