Table of Contents

Advantages of Using API Seamless Steel Casing for Oil Well Drilling

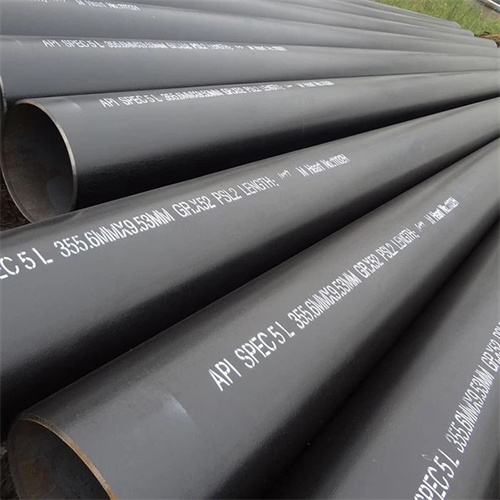

API seamless steel casing is a critical component in the oil and gas industry, particularly in oil well drilling in the oilfield. This type of casing is designed to provide structural support to the wellbore and protect the drilling operation from external pressures and environmental factors. API seamless steel casing is manufactured according to the American Petroleum Institute (API) standards, which ensure high quality and reliability in oilfield operations.

One of the key advantages of using API seamless steel casing for oil well drilling is its superior strength and durability. The seamless construction of this casing eliminates the weak points that are often found in welded casing, making it more resistant to high pressure and extreme temperatures. This strength and durability are essential for maintaining the integrity of the wellbore and preventing any potential leaks or failures during the drilling process.

In addition to its strength, API seamless steel casing also offers excellent corrosion resistance. The casing is typically coated with a protective layer, such as epoxy or Zinc, to prevent rust and corrosion from developing over time. This corrosion resistance is crucial for ensuring the longevity of the casing and maintaining the efficiency of the drilling operation.

Another advantage of using API seamless steel casing is its tight tolerances and uniformity in dimensions. This precision manufacturing process ensures that the casing fits snugly into the wellbore, creating a secure seal that prevents any fluid or gas from escaping. This tight fit also helps to maintain the stability of the wellbore and prevent any potential collapse or damage during the drilling process.

Furthermore, API seamless steel casing is highly versatile and can be customized to meet the specific requirements of each drilling operation. The casing is available in a variety of sizes, grades, and lengths, allowing for flexibility in design and construction. This versatility makes API seamless steel casing suitable for a wide range of drilling applications, from shallow wells to deep offshore drilling operations.

In conclusion, API seamless steel casing offers a number of advantages for oil well drilling in the oilfield. Its superior strength, durability, corrosion resistance, tight tolerances, and versatility make it an ideal choice for ensuring the success and efficiency of drilling operations. By using API seamless steel casing, oil and gas companies can enhance the Safety, reliability, and productivity of their drilling projects, ultimately leading to greater success in the oilfield.

How to Choose the Right API Seamless Steel Casing for Your Oilfield Operations

API seamless steel casing is an essential component in oil well drilling operations in the oilfield. It provides structural support to the wellbore and helps to prevent collapse, maintain well integrity, and control formation fluids. Choosing the right API seamless steel casing for your oilfield operations is crucial to ensure the success and efficiency of your drilling project.

When selecting API seamless steel casing, there are several factors to consider. The first consideration is the size and weight of the casing. API seamless steel casing comes in various sizes and weights, which are designated by API specifications. It is important to choose the appropriate size and weight of casing based on the wellbore diameter, depth, and formation characteristics. Using the wrong size or weight of casing can Lead to wellbore instability, casing failure, and other drilling problems.

Another important factor to consider when choosing API seamless steel casing is the grade of steel. API specifies different grades of steel for casing based on their mechanical properties, such as yield strength, tensile strength, and hardness. The grade of steel selected should be suitable for the specific drilling conditions, including well depth, temperature, pressure, and corrosive Environment. Using the wrong grade of steel can result in casing failure, leaks, and other wellbore integrity issues.

In addition to size, weight, and grade, it is also important to consider the Thread type and connection design of the API seamless steel casing. The thread type and connection design should be compatible with the drilling equipment and tools used in the oilfield. Using incompatible thread types or connection designs can lead to leaks, casing damage, and other operational problems. It is essential to ensure that the casing threads are properly sealed and tightened to prevent fluid migration and maintain wellbore integrity.

Furthermore, the coating and protection of API seamless steel casing should be taken into account when choosing the right casing for oilfield operations. Casing can be coated with various materials, such as epoxy, zinc, or Polymer, to protect against corrosion, abrasion, and other environmental factors. The coating selected should be suitable for the specific well conditions and provide long-term protection for the casing. Proper coating and protection can extend the life of the casing and reduce maintenance costs in the long run.

In conclusion, choosing the right API seamless steel casing for oil well drilling in the oilfield is essential for the success and efficiency of drilling operations. Factors to consider when selecting casing include size, weight, grade, thread type, connection design, coating, and protection. By carefully evaluating these factors and selecting the appropriate casing for the specific drilling conditions, operators can ensure the integrity and performance of their wells. API seamless steel casing plays a critical role in oilfield operations, and choosing the right casing is crucial for the success of drilling projects.