Table of Contents

Benefits of Using Aramid Staple Fiber Blended with Carbon Fiber in High-Temperature Applications

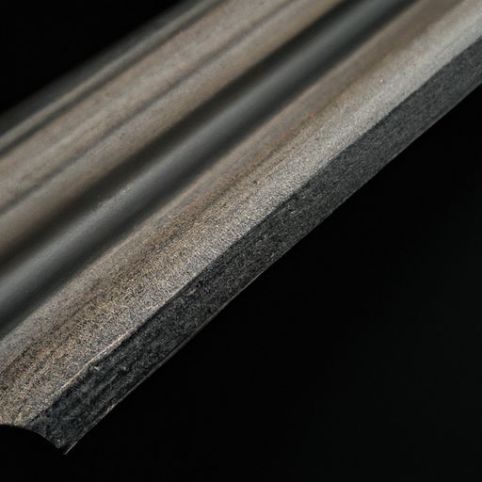

Aramid staple fiber blended with carbon fiber is a popular choice for high-temperature applications due to its unique combination of properties. This blend offers a balance of strength, heat resistance, and durability that make it ideal for use in a variety of industries, including aerospace, automotive, and industrial manufacturing.

One of the key benefits of using aramid staple fiber blended with carbon fiber is its high temperature resistance. Aramid fibers are known for their exceptional heat resistance, making them ideal for applications where exposure to high temperatures is a concern. When blended with carbon fiber, which also has excellent heat resistance properties, the resulting material is able to withstand even higher temperatures without losing its strength or integrity.

In addition to its high temperature resistance, aramid staple fiber blended with carbon fiber also offers exceptional strength and durability. Aramid fibers are known for their high tensile strength, making them ideal for applications where strength and durability are important. When blended with carbon fiber, which is also known for its strength and stiffness, the resulting material is able to withstand high Levels of stress and strain without breaking or deforming.

Another benefit of using aramid staple fiber blended with carbon fiber is its lightweight nature. Aramid fibers are lightweight and flexible, making them easy to work with and ideal for applications where weight is a concern. When blended with carbon fiber, which is also lightweight and has a high strength-to-weight ratio, the resulting material is able to provide the strength and durability needed for high-temperature applications without adding unnecessary weight.

Another benefit of using aramid staple fiber blended with carbon fiber is its lightweight nature. Aramid fibers are lightweight and flexible, making them easy to work with and ideal for applications where weight is a concern. When blended with carbon fiber, which is also lightweight and has a high strength-to-weight ratio, the resulting material is able to provide the strength and durability needed for high-temperature applications without adding unnecessary weight.

Furthermore, aramid staple fiber blended with carbon fiber is also resistant to Chemicals and abrasion. Aramid fibers are known for their resistance to chemicals and abrasion, making them ideal for applications where exposure to harsh chemicals or abrasive materials is a concern. When blended with carbon fiber, which also has excellent chemical resistance and abrasion resistance properties, the resulting material is able to withstand a wide range of environmental conditions without deteriorating or degrading.

Overall, the combination of properties offered by aramid staple fiber blended with carbon fiber makes it an ideal choice for high-temperature applications. Its high temperature resistance, strength, durability, lightweight nature, and resistance to chemicals and abrasion make it a versatile and reliable material for use in a variety of industries. Whether used in aerospace, automotive, or industrial manufacturing, aramid staple fiber blended with carbon fiber is sure to provide the performance and reliability needed for even the most demanding applications.

How to Choose the Best Aramid Staple Fiber with Carbon Fiber Blend for Cost-Effective Solutions

Aramid staple fiber with carbon fiber blend is a popular choice for applications that require high temperature resistance and durability. This unique blend of fibers offers a cost-effective solution for industries such as aerospace, automotive, and military where performance under extreme conditions is crucial. When choosing the best aramid staple fiber with carbon fiber blend, there are several factors to consider to ensure you are getting the most value for your investment.

One of the key considerations when selecting aramid staple fiber with carbon fiber blend is the denier and length of the fibers. The denier refers to the thickness of the fiber, with lower denier fibers being finer and higher denier fibers being thicker. A denier of 1.67dtex is a common choice for aramid staple fiber with carbon fiber blend, as it offers a good balance of strength and flexibility. The length of the fibers, typically 38mm, also plays a role in the performance of the blend, with longer fibers providing better tensile strength and shorter fibers offering improved abrasion resistance.

In addition to denier and length, the meta-aramid content of the blend is another important factor to consider. Meta-aramid fibers are known for their high temperature resistance and flame retardant properties, making them ideal for applications where heat and fire are a concern. A higher meta-aramid content in the blend will result in better overall performance in these areas, so it is important to choose a blend with a sufficient amount of meta-aramid fibers for your specific needs.

Another consideration when selecting aramid staple fiber with carbon fiber blend is the price. While aramid staple fiber with carbon fiber blend is generally more expensive than traditional fibers, the cost can vary depending on the quality and quantity of the fibers used. It is important to balance cost with performance when choosing a blend, as a higher quality blend may offer better long-term value by lasting longer and requiring less maintenance.

When comparing prices, it is also important to consider the reputation of the manufacturer. A reputable manufacturer with a history of producing high-quality aramid staple fiber with carbon fiber blend is more likely to provide a reliable product that meets your expectations. Look for manufacturers that have certifications or accreditations that demonstrate their commitment to quality and consistency in their products.

In conclusion, aramid staple fiber with carbon fiber blend is a versatile and cost-effective solution for applications that require high temperature resistance and durability. When choosing the best blend for your needs, consider factors such as denier, length, meta-aramid content, price, and manufacturer reputation to ensure you are getting the most value for your investment. By taking the time to research and compare different blends, you can find the perfect aramid staple fiber with carbon fiber blend for your specific requirements.