Table of Contents

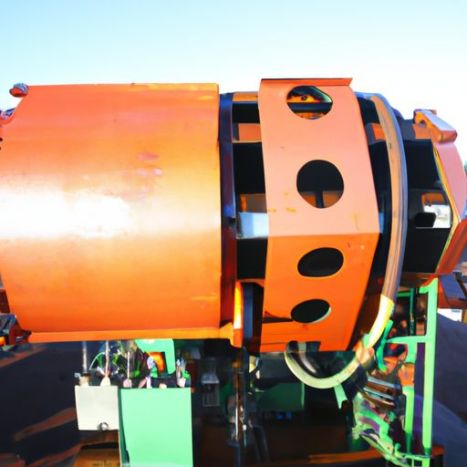

Desilting Cyclone: An Essential Component for Drilling Fluid Solid-Liquid Separation

In the realm of drilling operations, the efficient separation of solid particles from drilling fluid is crucial for maintaining the integrity of the drilling process. One key component that plays a vital role in this solid-liquid separation process is the desilting cyclone. This article will delve into the importance of desilting cyclones and how they contribute to the overall efficiency of drilling operations.

Desilting cyclones are designed to remove fine solids from drilling fluid, ensuring that the fluid remains clean and free of debris. These cyclones operate on the principle of centrifugal force, which causes the solid particles to separate from the liquid phase. The separated solids are then discharged through an outlet, while the clean drilling fluid is recirculated back into the system.

One of the main advantages of using desilting cyclones is their ability to handle a wide range of flow rates and solid concentrations. This flexibility makes them suitable for various drilling applications, from shallow wells to deep-sea drilling operations. Additionally, desilting cyclones are compact in size, making them easy to install and operate on drilling rigs with limited space.

Another key benefit of desilting cyclones is their cost-effectiveness. By removing solid particles from the drilling fluid, these cyclones help prevent equipment wear and tear, reducing maintenance costs in the long run. Additionally, clean drilling fluid leads to improved drilling performance and higher productivity, ultimately saving time and money for drilling companies.

Another key benefit of desilting cyclones is their cost-effectiveness. By removing solid particles from the drilling fluid, these cyclones help prevent equipment wear and tear, reducing maintenance costs in the long run. Additionally, clean drilling fluid leads to improved drilling performance and higher productivity, ultimately saving time and money for drilling companies.

In addition to desilting cyclones, mud shale solids control shakers are another essential component for solid-liquid separation in drilling operations. These shakers use vibrating screens to separate solid particles from drilling fluid, ensuring that the fluid remains clean and free of contaminants. Mud shale solids control shakers work in conjunction with desilting cyclones to provide a comprehensive solution for solid-liquid separation in drilling operations.

The HCS series desander with a desilting cyclone and mud shale solids control shaker is a powerful combination that offers superior performance in solid-liquid separation. The desander removes larger solid particles from the drilling fluid, while the mud shale solids control shaker further refines the separation process by removing finer particles. This dual-stage system ensures that the drilling fluid remains clean and free of debris, enhancing the overall efficiency of drilling operations.

In conclusion, desilting cyclones are an essential component for solid-liquid separation in drilling operations. Their ability to remove fine solids from drilling fluid, coupled with their cost-effectiveness and versatility, makes them a valuable asset for drilling companies. When combined with mud shale solids control shakers, desilting cyclones offer a comprehensive solution for maintaining clean drilling fluid and optimizing drilling performance. By investing in high-quality desilting cyclones and mud shale solids control shakers, drilling companies can ensure smooth and efficient drilling operations, ultimately leading to increased productivity and profitability.