Table of Contents

Benefits of Frequency Micro Eddy Current Heating in Shaft Welding Positioners

Frequency micro eddy current heating technology has revolutionized the world of shaft welding positioners, offering a wide range of benefits that make it a popular choice among manufacturers. This innovative technology utilizes high-frequency currents to generate heat directly within the material being welded, resulting in faster and more efficient heating compared to traditional methods. In this article, we will explore the various advantages of using frequency micro eddy current heating in shaft welding positioners.

One of the key benefits of frequency micro eddy current heating is its ability to provide precise and uniform heating throughout the material. This is essential in shaft welding applications, where even heating is crucial to ensure a strong and reliable weld. By generating heat directly within the material, frequency micro eddy current heating eliminates the risk of overheating or underheating certain areas, resulting in a more consistent and high-quality weld.

Another advantage of frequency micro eddy current heating is its energy efficiency. Traditional heating methods often require a significant amount of energy to heat the material, leading to higher operating costs and increased environmental impact. In contrast, frequency micro eddy current heating is highly efficient, requiring less energy to achieve the same level of heating. This not only helps manufacturers reduce their energy consumption and operating costs but also contributes to a more sustainable and environmentally friendly manufacturing process.

In addition to its precision and energy efficiency, frequency micro eddy current heating offers faster heating times compared to traditional methods. This is particularly beneficial in shaft welding applications, where time is of the essence. By quickly and efficiently heating the material, frequency micro eddy current heating helps manufacturers increase their productivity and meet tight production deadlines.

Furthermore, frequency micro eddy current heating is a versatile technology that can be easily integrated into existing shaft welding positioners. This makes it a cost-effective solution for manufacturers looking to upgrade their Welding Equipment without having to invest in entirely new systems. By simply retrofitting their existing positioners with frequency micro eddy current heating technology, manufacturers can enjoy all the benefits of this innovative heating method without the need for a complete overhaul of their equipment.

One of the most significant advantages of frequency micro eddy current heating in shaft welding positioners is its ability to produce high-quality welds with minimal distortion. Traditional heating methods can often Lead to distortion in the material being welded, resulting in weak and unreliable welds. Frequency micro eddy current heating, on the other hand, produces a clean and precise heat that minimizes distortion and ensures a strong and durable weld.

In conclusion, frequency micro eddy current heating technology offers a wide range of benefits for manufacturers using shaft welding positioners. From its precise and uniform heating to its energy efficiency and fast heating times, this innovative technology is revolutionizing the world of welding. By integrating frequency micro eddy current heating into their positioners, manufacturers can enjoy increased productivity, reduced operating costs, and high-quality welds with minimal distortion.

Comparison of Lead-Free Soldering Stations: Anti-Static Smart Soldering Iron BK1000 vs. Bakon 90W High

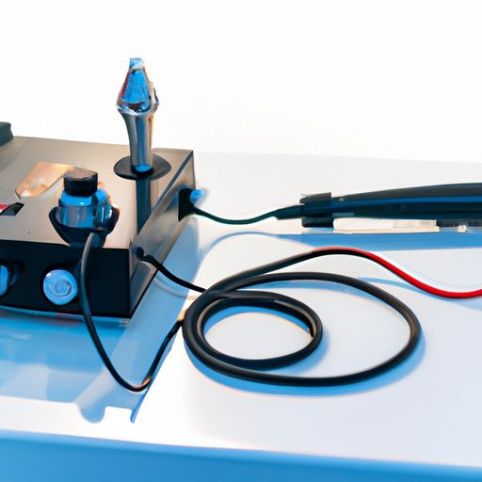

When it comes to lead-free soldering stations, two popular options on the market are the Anti-Static Smart Soldering Iron BK1000 and the Bakon 90W High. Both of these soldering stations offer advanced features and capabilities that make them ideal for a variety of soldering applications. In this article, we will compare the two soldering stations in terms of their performance, features, and overall value.

The Anti-Static Smart Soldering Iron BK1000 is a high-quality soldering station that is designed for precision soldering tasks. It features a frequency micro eddy current heating shaft that provides fast and efficient heating, allowing for quick and precise soldering. The BK1000 also comes equipped with a welding positioner that helps to hold the workpiece in place during soldering, ensuring accurate and consistent results.

The Anti-Static Smart Soldering Iron BK1000 is a high-quality soldering station that is designed for precision soldering tasks. It features a frequency micro eddy current heating shaft that provides fast and efficient heating, allowing for quick and precise soldering. The BK1000 also comes equipped with a welding positioner that helps to hold the workpiece in place during soldering, ensuring accurate and consistent results.

In comparison, the Bakon 90W High soldering station is also a top-of-the-line option that offers excellent performance and reliability. It features a lead-free soldering station that is designed to meet the latest industry standards for environmental Safety. The Bakon 90W High also comes with an anti-static smart soldering iron that helps to prevent damage to sensitive electronic components during soldering.

One of the key differences between the two soldering stations is their power output. The Anti-Static Smart Soldering Iron BK1000 has a power output of 100 watts, while the Bakon 90W High has a slightly lower power output of 90 watts. While this may not seem like a significant difference, it can impact the speed and efficiency of the soldering process, especially when working on larger or more complex projects.

In terms of features, both soldering stations offer a range of advanced capabilities that make them versatile and easy to use. The BK1000 comes with a range of temperature settings that can be adjusted to suit different soldering tasks, while the Bakon 90W High features a digital display that provides real-time feedback on the temperature of the soldering iron.

Another important factor to consider when comparing these two soldering stations is their overall value. The Anti-Static Smart Soldering Iron BK1000 is priced slightly higher than the Bakon 90W High, but it offers a range of advanced features and capabilities that make it worth the investment for serious hobbyists and professionals. The Bakon 90W High, on the other hand, is a more budget-friendly option that still offers excellent performance and reliability.

In conclusion, both the Anti-Static Smart Soldering Iron BK1000 and the Bakon 90W High are excellent options for lead-free soldering applications. While the BK1000 offers slightly higher power output and more advanced features, the Bakon 90W High provides solid performance at a more affordable price point. Ultimately, the best soldering station for you will depend on your specific needs and budget.