Table of Contents

Benefits of Using J55, K55, L80, N80, P110 API Casing Tubing in Oil and Gas Industry

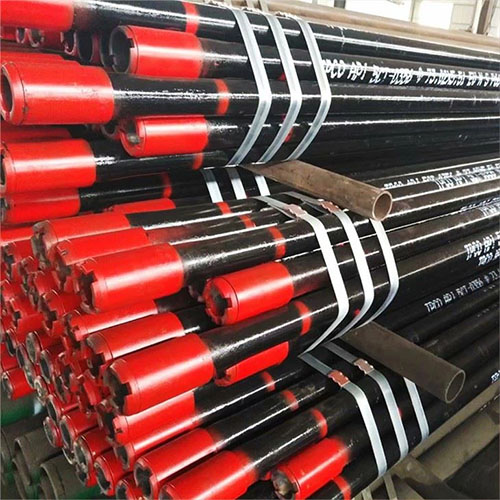

API casing tubing is an essential component in the oil and gas industry, providing structural support and protection for oil and gas wells. There are several grades of API casing tubing available, each with its own unique properties and benefits. In this article, we will explore the benefits of using J55, K55, L80, N80, and P110 API casing tubing in the oil and gas industry.

J55 API casing tubing is a common grade used in oil and gas wells. It has a high tensile strength and is resistant to corrosion, making it ideal for use in harsh environments. J55 casing tubing is also easy to weld and has good machinability, making it a cost-effective option for oil and gas companies.

K55 API casing tubing is similar to J55 in terms of its properties, but it has a higher yield strength. This makes K55 casing tubing more suitable for wells with higher pressure and temperature requirements. K55 casing tubing is also more resistant to cracking and has a longer service life, making it a popular choice for oil and gas companies.

L80 API casing tubing is a high-strength grade that is commonly used in deep wells and offshore drilling operations. L80 casing tubing has excellent mechanical properties and is highly resistant to corrosion, making it ideal for use in challenging environments. L80 casing tubing is also easy to weld and has good formability, making it a versatile option for oil and gas companies.

N80 API casing tubing is another popular grade used in the oil and gas industry. N80 casing tubing has a higher yield strength than J55 and K55, making it suitable for wells with higher pressure and temperature requirements. N80 casing tubing is also highly resistant to corrosion and has good weldability, making it a reliable choice for oil and gas companies.

P110 API casing tubing is a premium grade that is used in high-pressure and high-temperature wells. P110 casing tubing has a higher yield strength and is more resistant to cracking than other grades, making it ideal for challenging drilling conditions. P110 casing tubing is also highly resistant to corrosion and has excellent weldability, making it a top choice for oil and gas companies.

In conclusion, J55, K55, L80, N80, and P110 API casing tubing are all excellent choices for use in the oil and gas industry. Each grade has its own unique properties and benefits, making them suitable for a wide range of drilling applications. Whether you are drilling in a harsh Environment or a deep offshore well, there is an API casing tubing grade that will meet your needs. By choosing the right grade of API casing tubing, you can ensure the success of your drilling operations and maximize the productivity of your oil and gas wells.

Comparison of Mechanical Properties of J55, K55, L80, N80, P110 API Casing Tubing

API casing tubing is an essential component in the oil and gas industry, used to protect and support the wellbore during drilling and completion operations. There are several grades of API casing tubing available, each with its own unique mechanical properties that make them suitable for different applications. In this article, we will compare the mechanical properties of five common grades of API casing tubing: J55, K55, L80, N80, and P110.

J55 is a low Carbon Steel grade that is commonly used in shallow wells where the casing does not experience high stress or pressure. It has a minimum yield strength of 55,000 psi and a minimum tensile strength of 75,000 psi. J55 is known for its excellent weldability and is often used in casing strings that require welding.

K55 is another low carbon steel grade that is similar to J55 in terms of its mechanical properties. It has a minimum yield strength of 55,000 psi and a minimum tensile strength of 95,000 psi. K55 is often used in casing strings that require higher tensile strength than J55 but do not require the higher cost of grades like L80 or P110.

L80 is a medium carbon steel grade that is commonly used in medium to high pressure wells. It has a minimum yield strength of 80,000 psi and a minimum tensile strength of 95,000 psi. L80 is known for its excellent resistance to corrosion and is often used in casing strings that are exposed to corrosive environments.

N80 is a medium carbon steel grade that is similar to L80 in terms of its mechanical properties. It has a minimum yield strength of 80,000 psi and a minimum tensile strength of 95,000 psi. N80 is often used in casing strings that require higher tensile strength than J55 or K55 but do not require the higher cost of grades like L80 or P110.

P110 is a high strength steel grade that is commonly used in high pressure wells. It has a minimum yield strength of 110,000 psi and a minimum tensile strength of 140,000 psi. P110 is known for its excellent resistance to deformation under high pressure and is often used in casing strings that are exposed to high pressure environments.

In conclusion, the choice of API casing tubing grade depends on the specific requirements of the wellbore and the operating conditions. J55 and K55 are suitable for shallow wells with low stress and pressure, while L80 and N80 are suitable for medium to high pressure wells with corrosive environments. P110 is suitable for high pressure wells that require high strength and resistance to deformation. By understanding the mechanical properties of each grade, operators can make informed decisions about which grade of API casing tubing is best suited for their specific application.