Table of Contents

Benefits of Using Custom Submersible Sewage Pump Sand Dredging

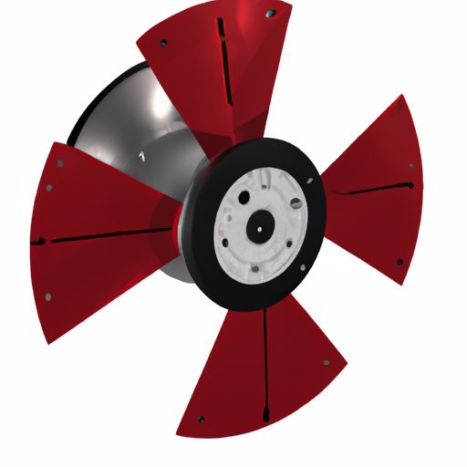

Jet pump impeller custom submersible sewage pump sand dredging cast Iron vacuum impeller is a crucial component in the process of removing sand and debris from sewage systems. This specialized impeller is designed to handle the tough conditions of sewage pumping, making it an essential tool for maintaining the efficiency and functionality of sewage systems. In this article, we will explore the benefits of using a custom submersible sewage pump sand dredging cast iron vacuum impeller.

One of the key benefits of using a custom submersible sewage pump sand dredging cast iron vacuum impeller is its durability. Made from high-quality cast iron, this impeller is built to withstand the harsh conditions of sewage pumping. Its robust construction ensures that it can handle the abrasive nature of sand and debris without succumbing to wear and tear. This durability translates to a longer lifespan for the impeller, reducing the need for frequent replacements and maintenance.

In addition to its durability, a custom submersible sewage pump sand dredging cast iron vacuum impeller is also highly efficient. Its design allows for optimal flow rates and performance, ensuring that sand and debris are efficiently removed from sewage systems. This efficiency not only improves the overall functionality of the sewage system but also helps to reduce energy consumption, making it a cost-effective solution for sewage pumping needs.

Furthermore, a custom submersible sewage pump sand dredging cast iron vacuum impeller is versatile and can be customized to meet specific requirements. Whether you need a larger impeller for heavy-duty sand dredging or a smaller impeller for more precise pumping tasks, a custom impeller can be tailored to suit your needs. This flexibility allows for greater adaptability in various sewage pumping applications, making it a versatile and practical solution for sewage system maintenance.

Another benefit of using a custom submersible sewage pump sand dredging cast iron vacuum impeller is its ease of installation and maintenance. Designed for simple and straightforward installation, this impeller can be easily integrated into existing sewage systems without the need for extensive modifications. Additionally, its durable construction minimizes the need for frequent maintenance, reducing downtime and ensuring continuous operation of the sewage system.

Overall, a custom submersible sewage pump sand dredging cast iron vacuum impeller offers a range of benefits that make it an essential tool for sewage system maintenance. From its durability and efficiency to its versatility and ease of installation, this specialized impeller provides a reliable and cost-effective solution for handling sand and debris in sewage systems. Whether you are looking to improve the performance of your sewage system or reduce maintenance costs, a custom submersible sewage pump sand dredging cast iron vacuum impeller is a valuable investment that can help you achieve your goals.

Advantages of Cast Iron Vacuum Impeller for Jet Pump Applications

Jet Pumps are commonly used in various applications, including sewage pumping and sand dredging. One crucial component of a jet pump is the impeller, which plays a vital role in the pump’s performance. When it comes to jet pump Impellers, cast iron vacuum impellers are a popular choice due to their numerous advantages.

One of the primary advantages of cast iron vacuum impellers is their durability. Cast iron is known for its strength and resistance to wear and tear, making it an ideal material for impellers that are subjected to high Levels of stress and abrasion. This durability ensures that the impeller can withstand the harsh conditions often encountered in sewage pumping and sand dredging applications, resulting in a longer lifespan for the pump.

One of the primary advantages of cast iron vacuum impellers is their durability. Cast iron is known for its strength and resistance to wear and tear, making it an ideal material for impellers that are subjected to high Levels of stress and abrasion. This durability ensures that the impeller can withstand the harsh conditions often encountered in sewage pumping and sand dredging applications, resulting in a longer lifespan for the pump.

In addition to durability, cast iron vacuum impellers also offer excellent corrosion resistance. This is particularly important in applications where the pump is exposed to corrosive materials such as sewage or saltwater. The corrosion-resistant properties of cast iron ensure that the impeller remains in optimal condition, even when exposed to harsh Chemicals or environments.

Furthermore, cast iron vacuum impellers are known for their high efficiency. The design of the impeller allows for maximum flow rates and pressure, resulting in improved performance and energy savings. This efficiency is crucial in applications such as sand dredging, where the pump needs to move large volumes of material quickly and efficiently.

Another advantage of cast iron vacuum impellers is their versatility. These impellers can be customized to meet specific requirements, making them suitable for a wide range of jet pump applications. Whether you need a larger impeller for increased flow rates or a specialized design for unique pumping conditions, cast iron vacuum impellers can be tailored to suit your needs.

In addition to their durability, corrosion resistance, efficiency, and versatility, cast iron vacuum impellers are also cost-effective. While the initial investment may be slightly higher than other materials, the long-term benefits of using cast iron impellers far outweigh the upfront costs. With their extended lifespan and superior performance, cast iron vacuum impellers offer excellent value for money.

Overall, cast iron vacuum impellers are an excellent choice for jet pump applications, particularly in sewage pumping and sand dredging. Their durability, corrosion resistance, efficiency, versatility, and cost-effectiveness make them a reliable and efficient option for various pumping needs. Whether you are looking to upgrade your existing pump or invest in a new one, consider the advantages of cast iron vacuum impellers for optimal performance and longevity.