Table of Contents

Sustainable Materials for Women’s Cardigans Production

Women’s cardigans are a staple in many Wardrobes, providing both style and warmth during the cooler months. As the fashion industry continues to evolve, there is a growing demand for sustainable and eco-friendly materials in clothing production. This shift towards sustainability has led many women’s cardigan factories to explore new materials and production methods that are better for the Environment.

One of the key considerations in producing sustainable women’s cardigans is the choice of materials. Traditional materials like cotton and wool have long been popular choices for cardigans, but their production can have a significant impact on the environment. Cotton, for example, requires large amounts of water and Pesticides to grow, while wool production can contribute to overgrazing and soil degradation.

To address these environmental concerns, many women’s cardigan factories are turning to more sustainable materials like organic cotton, bamboo, and recycled fibers. Organic cotton is grown without the use of synthetic pesticides or fertilizers, making it a more environmentally friendly option. Bamboo is a fast-growing plant that requires minimal water and pesticides, making it a sustainable alternative to traditional materials. Recycled fibers, made from post-consumer waste like Plastic Bottles, offer a way to reduce the environmental impact of clothing production.

In addition to choosing sustainable materials, women’s cardigan factories are also exploring more eco-friendly production methods. One approach is to use natural dyes made from plants and Minerals, which are less harmful to the environment than synthetic dyes. Another option is to implement water-saving techniques in the dyeing and finishing process, reducing the amount of water used and minimizing pollution.

Furthermore, some women’s cardigan factories are investing in Renewable Energy sources like solar and wind power to reduce their carbon footprint. By using clean energy to power their production facilities, these factories can lower their greenhouse gas emissions and contribute to a more sustainable fashion industry.

Overall, the shift towards sustainable materials and production methods in women’s cardigan factories is a positive step towards a more environmentally friendly fashion industry. By choosing materials that are better for the planet and implementing eco-friendly production practices, these factories can reduce their impact on the environment and create clothing that is both stylish and sustainable.

In conclusion, the production of women’s cardigans in factories is evolving to prioritize sustainability and eco-friendliness. By choosing sustainable materials like organic cotton, bamboo, and recycled fibers, and implementing eco-friendly production methods like natural dyes and renewable energy sources, women’s cardigan factories are making a positive impact on the environment. As consumers become more conscious of the environmental impact of their clothing choices, the demand for sustainable women’s cardigans is likely to continue to grow. By embracing sustainability in their production processes, women’s cardigan factories can help shape a more sustainable future for the fashion industry.

Trends in Women’s Cardigans Manufacturing Industry

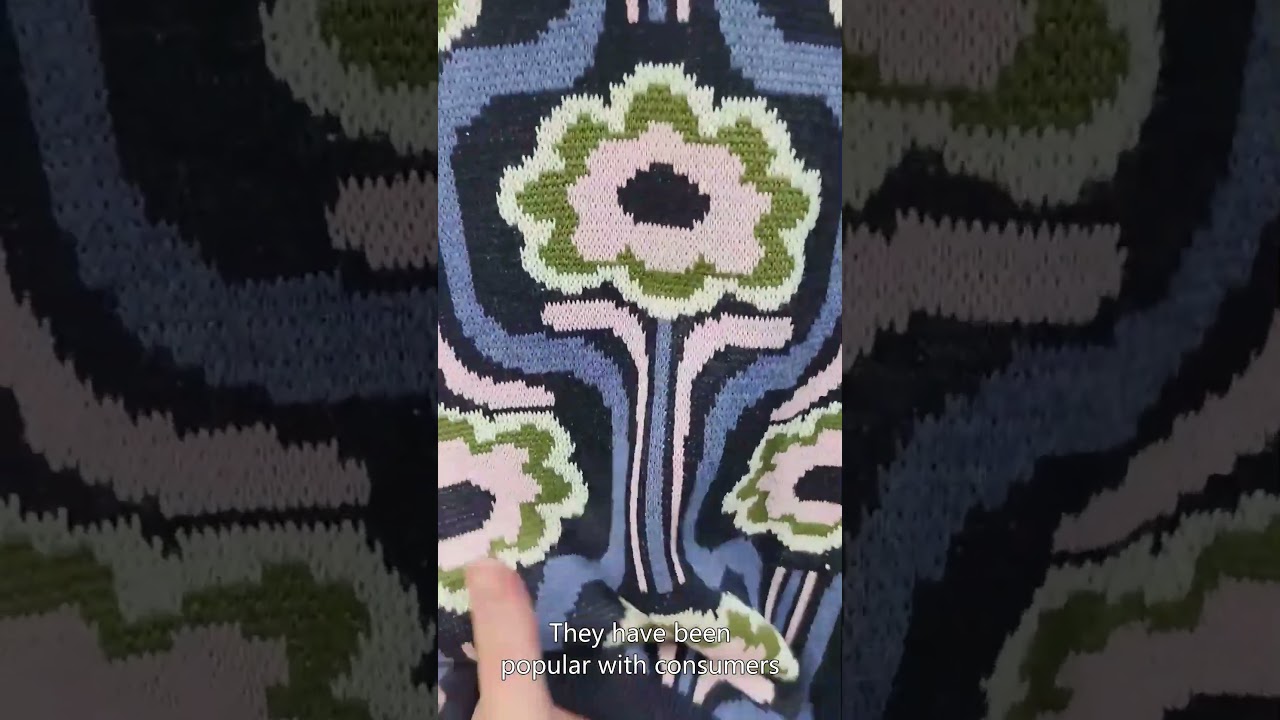

The production of women’s cardigans is a thriving industry that continues to evolve with changing trends and consumer demands. As more and more women seek stylish and comfortable clothing options, manufacturers are constantly innovating to meet these needs. One key aspect of this industry is the production process itself, which involves a series of steps from design to distribution.

The first step in producing women’s cardigans is the design phase. Designers work to create unique and fashionable styles that will appeal to consumers. They take into account current trends, color Palettes, and fabric choices to create a cohesive collection. Once the designs are finalized, they are sent to the production team to begin the manufacturing process.

| No. | Product category | Fabric variety | Supply model |

| 2 | custom knit | POLYESTER | Sweater customized |

The next step in production is sourcing materials. Women’s cardigans can be made from a variety of fabrics, including wool, cotton, and synthetic blends. Manufacturers must carefully select high-quality materials that will result in a durable and comfortable product. Once the materials are sourced, they are sent to the factory for cutting and sewing.

The cutting and sewing process is where the cardigans start to take shape. Skilled workers use patterns to cut the fabric into pieces that will eventually be assembled into the final product. Sewing Machines are used to stitch the pieces together, creating the body of the cardigan. Details such as Buttons, zippers, and pockets are added during this stage.

After the cardigans are sewn together, they are inspected for quality control. Any defects or imperfections are addressed and corrected before the garments move on to the next stage of production. Once the cardigans pass inspection, they are sent to be washed and finished. This process helps to soften the fabric and give the cardigans a polished look.

The final step in production is packaging and distribution. Cardigans are folded, tagged, and packaged for shipment to retailers or directly to consumers. Manufacturers must carefully label each garment with size, care instructions, and branding information. Once packaged, the cardigans are shipped to their final destination, ready to be sold to eager customers.

In recent years, there has been a growing trend towards sustainable and ethical manufacturing practices in the women’s cardigan industry. Consumers are increasingly concerned about the environmental and social impact of their clothing choices, leading many manufacturers to prioritize sustainability in their production processes. This includes using eco-friendly materials, reducing waste, and ensuring fair labor practices.

Overall, the production of women’s cardigans is a complex and multifaceted process that requires careful attention to detail and quality. From design to distribution, manufacturers must navigate a variety of challenges to create stylish and comfortable garments that meet consumer demands. As trends continue to evolve, the industry will likely see further innovations in production techniques and materials, ensuring that women’s cardigans remain a staple in fashion for years to come.