Table of Contents

Benefits of Using Resistant Elastomer BRE 7231 (BRE7231) FKM Resin

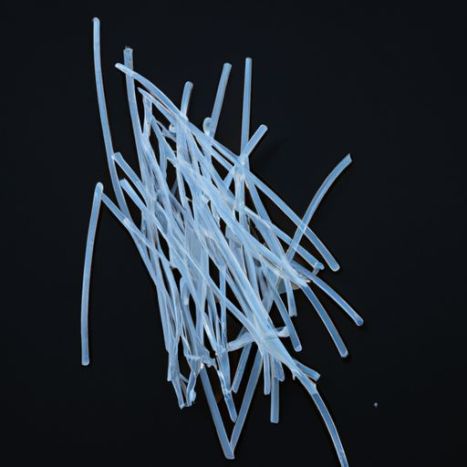

Resistant Elastomer BRE 7231 (BRE7231) FKM Resin is a high-performance material that offers exceptional abrasion resistance. Developed by 3M Dyneon, this elastomer is specifically designed to withstand harsh environments and demanding applications. In this article, we will explore the benefits of using Resistant Elastomer BRE 7231 (BRE7231) FKM Resin and why it is a preferred choice for many industries.

One of the key advantages of Resistant Elastomer BRE 7231 (BRE7231) FKM Resin is its superior abrasion resistance. This material is highly resistant to wear and tear, making it ideal for applications where durability is essential. Whether it is exposed to harsh Chemicals, extreme temperatures, or high Levels of friction, this elastomer can withstand the toughest conditions without compromising its performance.

In addition to its exceptional abrasion resistance, Resistant Elastomer BRE 7231 (BRE7231) FKM Resin also offers excellent chemical resistance. This material is resistant to a wide range of chemicals, including acids, bases, solvents, and oils. This makes it a versatile choice for applications where exposure to corrosive substances is a concern. With Resistant Elastomer BRE 7231 (BRE7231) FKM Resin, you can trust that your equipment will remain protected and reliable in even the harshest environments.

Furthermore, Resistant Elastomer BRE 7231 (BRE7231) FKM Resin is known for its high temperature resistance. This material can withstand temperatures ranging from -20\u00b0C to 200\u00b0C, making it suitable for applications where heat resistance is crucial. Whether it is used in automotive, aerospace, or industrial applications, this elastomer can maintain its integrity and performance even in extreme temperature conditions.

Another benefit of using Resistant Elastomer BRE 7231 (BRE7231) FKM Resin is its excellent mechanical properties. This material is highly flexible and can be easily molded into various shapes and sizes. It also has a low compression set, which means it can maintain its shape and elasticity over time. With its superior mechanical properties, this elastomer is a reliable choice for applications that require flexibility, resilience, and longevity.

Moreover, Resistant Elastomer BRE 7231 (BRE7231) FKM Resin is easy to process and can be customized to meet specific requirements. Whether you need a specific color, hardness, or texture, this material can be tailored to suit your needs. With its versatility and customization options, Resistant Elastomer BRE 7231 (BRE7231) FKM Resin offers endless possibilities for a wide range of applications.

Moreover, Resistant Elastomer BRE 7231 (BRE7231) FKM Resin is easy to process and can be customized to meet specific requirements. Whether you need a specific color, hardness, or texture, this material can be tailored to suit your needs. With its versatility and customization options, Resistant Elastomer BRE 7231 (BRE7231) FKM Resin offers endless possibilities for a wide range of applications.

In conclusion, Resistant Elastomer BRE 7231 (BRE7231) FKM Resin is a high-performance material that offers exceptional abrasion resistance, chemical resistance, temperature resistance, and mechanical properties. With its durability, reliability, and versatility, this elastomer is a preferred choice for many industries, including automotive, aerospace, and industrial applications. If you are looking for a material that can withstand the toughest conditions and deliver superior performance, Resistant Elastomer BRE 7231 (BRE7231) FKM Resin is the ideal choice for your next project.

Comparison of Abrasion Resistance of Resistant Elastomer BRE 7231 (BRE7231) FKM Resin and 3M Dyneon Base

Resistant Elastomer BRE 7231 (BRE7231) FKM Resin and 3M Dyneon Base are two popular materials known for their abrasion resistance properties. Abrasion resistance is a critical factor in many industries, as it determines the material’s ability to withstand wear and tear over time. In this article, we will compare the abrasion resistance of Resistant Elastomer BRE 7231 (BRE7231) FKM Resin and 3M Dyneon Base to help you make an informed decision when choosing a material for your application.

Resistant Elastomer BRE 7231 (BRE7231) FKM Resin is a fluorinated elastomer known for its excellent resistance to heat, chemicals, and abrasion. It is commonly used in applications where high temperatures and harsh chemicals are present, such as in the automotive and aerospace industries. The abrasion resistance of BRE7231 FKM Resin is attributed to its unique molecular structure, which allows it to maintain its integrity even under extreme conditions.

On the other hand, 3M Dyneon Base is a fluoropolymer material that also offers excellent abrasion resistance. It is known for its low friction properties, making it ideal for applications where sliding or rubbing against other surfaces is common. The abrasion resistance of 3M Dyneon Base is achieved through a combination of its molecular structure and the addition of special additives that enhance its wear resistance.

When comparing the abrasion resistance of Resistant Elastomer BRE 7231 (BRE7231) FKM Resin and 3M Dyneon Base, it is important to consider the specific requirements of your application. While both materials offer excellent abrasion resistance, they may perform differently in different environments. For example, if your application involves exposure to high temperatures or harsh chemicals, Resistant Elastomer BRE 7231 (BRE7231) FKM Resin may be the better choice due to its superior heat and chemical resistance.

On the other hand, if your application requires low friction properties in addition to abrasion resistance, 3M Dyneon Base may be the more suitable option. Its low friction properties can help reduce wear and tear on moving parts, leading to longer-lasting performance.

In conclusion, both Resistant Elastomer BRE 7231 (BRE7231) FKM Resin and 3M Dyneon Base offer excellent abrasion resistance properties. The choice between the two materials will ultimately depend on the specific requirements of your application. Consider factors such as temperature, chemical exposure, and friction when making your decision. By choosing the right material for your application, you can ensure long-lasting performance and durability.