Table of Contents

Blog Topic About Spline Hob Pre-Grinding

Spline hob pre-grinding is a crucial step in the manufacturing process of cutting Hobs. Cutting hobs are used in Gear Cutting Machines to produce gears with precise teeth profiles. The pre-grinding of spline hobs ensures that the cutting edges are sharp and accurately shaped, leading to high-quality gear production.

Before the actual hobbing process takes place, the spline hob undergoes pre-grinding to prepare it for the cutting operation. This pre-grinding step involves shaping the cutting edges of the hob to the desired profile. The goal is to create sharp, clean cutting edges that will produce accurate gear teeth.

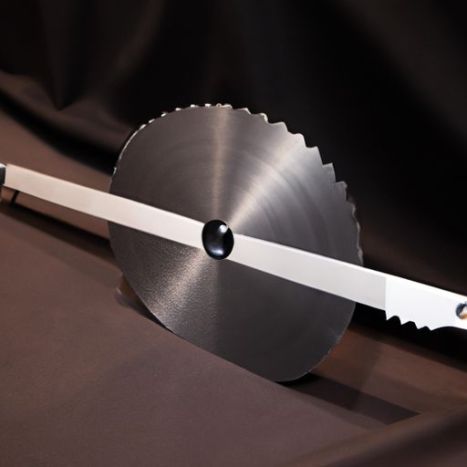

The pre-grinding of spline hobs is typically done using specialized grinding machines that are designed to precisely shape the cutting edges of the hob. These machines use abrasive Grinding Wheels to remove material from the hob and create the desired tooth profile. The process requires careful control and precision to ensure that the hob is accurately shaped.

One of the key benefits of pre-grinding spline hobs is that it allows for the production of high-quality gears. Sharp cutting edges on the hob result in clean, precise gear teeth that mesh smoothly and accurately. This is essential for ensuring the proper functioning of gears in various mechanical systems.

One of the key benefits of pre-grinding spline hobs is that it allows for the production of high-quality gears. Sharp cutting edges on the hob result in clean, precise gear teeth that mesh smoothly and accurately. This is essential for ensuring the proper functioning of gears in various mechanical systems.

In addition to producing high-quality gears, pre-grinding spline hobs also helps to extend the life of the cutting tool. By shaping the cutting edges before the hobbing process, the tool is less likely to wear out quickly during operation. This can Lead to cost savings for manufacturers by reducing the frequency of tool replacement.

Another important aspect of spline hob pre-grinding is the ability to produce nonstandard gear profiles. While standard involute gear profiles are commonly used, there are situations where nonstandard profiles are required. Pre-grinding allows for the customization of cutting hobs to produce gears with unique tooth profiles.

When it comes to pre-shaving hobs, the same principles apply. Pre-shaving hobs are used to remove material from the gear teeth before the final hobbing operation. This helps to improve the surface finish of the gears and ensure that they meet the required specifications.

Overall, spline hob pre-grinding is a critical step in the gear manufacturing process. It allows for the production of high-quality gears with precise tooth profiles, extends the life of cutting tools, and enables the customization of gear profiles. By investing in pre-Grinding Equipment and processes, manufacturers can ensure that their gears meet the highest standards of quality and performance.