Table of Contents

Advantages of Using Stainless Steel Pipes in Industrial Applications

Stainless Steel Pipes are a popular choice in various industrial applications due to their numerous advantages. These pipes are known for their durability, corrosion resistance, and high strength, making them ideal for use in a wide range of industries. In this article, we will explore the advantages of using stainless steel pipes in industrial applications.

One of the key advantages of stainless steel pipes is their corrosion resistance. Stainless steel is highly resistant to corrosion, making it ideal for use in environments where exposure to moisture or Chemicals is common. This corrosion resistance helps to extend the lifespan of the pipes, reducing the need for frequent replacements and maintenance.

In addition to their corrosion resistance, stainless steel pipes are also known for their high strength. Stainless steel is a strong material that can withstand high pressure and temperature, making it suitable for use in demanding industrial applications. This high strength helps to ensure the integrity of the pipes, even in harsh operating conditions.

Another advantage of stainless steel pipes is their durability. Stainless steel is a durable material that can withstand wear and tear, making it a long-lasting choice for industrial applications. This durability helps to reduce the risk of leaks or failures, ensuring the reliable operation of the system.

Stainless steel pipes are also easy to clean and maintain, making them a convenient choice for industrial applications. The smooth surface of stainless steel pipes makes them easy to clean, helping to prevent the buildup of debris or contaminants. This ease of maintenance helps to ensure the hygiene and efficiency of the system.

Furthermore, stainless steel pipes are environmentally friendly. Stainless steel is a recyclable material, making it a sustainable choice for industrial applications. By using stainless steel pipes, companies can reduce their environmental impact and contribute to a more sustainable future.

Stainless steel pipes are also versatile, with a wide range of sizes and shapes available to suit different industrial applications. Whether you need a small diameter pipe for a precise application or a large diameter pipe for a high-volume system, stainless steel pipes can meet your requirements.

In conclusion, stainless steel pipes offer numerous advantages for industrial applications. From their corrosion resistance and high strength to their durability and ease of maintenance, stainless steel pipes are a reliable and sustainable choice for a wide range of industries. By choosing stainless steel pipes, companies can benefit from a long-lasting and efficient solution for their industrial piping needs.

The Process of Galvanizing Steel Pipes: Benefits and Applications

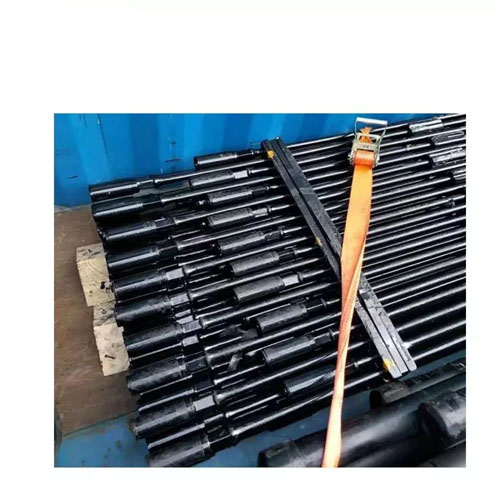

Steel pipes are a crucial component in various industries, from construction to manufacturing. They are used for Transporting fluids, gases, and even solids. One common method of protecting steel pipes from corrosion is galvanization. Galvanizing steel pipes involves coating them with a layer of Zinc to prevent rust and corrosion. This process offers numerous benefits and has a wide range of applications in different industries.

Galvanizing steel pipes is a process that has been around for centuries. It involves immersing the steel pipes in a bath of molten zinc, which creates a protective layer on the surface of the pipes. This layer of zinc acts as a barrier between the steel and the Environment, preventing rust and corrosion from forming. Galvanized steel pipes are known for their durability and longevity, making them ideal for outdoor applications where they are exposed to harsh weather conditions.

One of the main benefits of galvanizing steel pipes is its corrosion resistance. The zinc coating on the pipes provides a protective barrier that prevents rust and corrosion from forming. This makes galvanized steel pipes ideal for use in outdoor applications where they are exposed to moisture, humidity, and other corrosive elements. Galvanized steel pipes are also resistant to abrasion and impact, making them suitable for use in high-traffic areas.

Another benefit of galvanizing steel pipes is its low maintenance requirements. Galvanized steel pipes require minimal upkeep compared to other types of steel pipes. The zinc coating on the pipes helps to extend their lifespan, reducing the need for frequent repairs or replacements. This makes galvanized steel pipes a cost-effective option for many industries.

Galvanized steel pipes are also environmentally friendly. The zinc coating on the pipes is recyclable, making galvanized steel pipes a sustainable choice for many applications. Additionally, the longevity of galvanized steel pipes reduces the need for frequent replacements, which helps to conserve resources and reduce waste.

The applications of galvanized steel pipes are vast and varied. They are commonly used in construction for water supply lines, gas pipelines, and structural support. Galvanized steel pipes are also used in Agriculture for irrigation systems and fencing. In the automotive industry, galvanized steel pipes are used for exhaust systems and chassis components. The versatility and durability of galvanized steel pipes make them a popular choice in many industries.

In conclusion, galvanizing steel pipes is a process that offers numerous benefits and has a wide range of applications. The corrosion resistance, low maintenance requirements, and environmental sustainability of galvanized steel pipes make them an ideal choice for many industries. Whether used in construction, agriculture, automotive, or other applications, galvanized steel pipes provide a reliable and durable solution for transporting fluids, gases, and solids. Consider galvanized steel pipes for your next project to benefit from their protective coating and long-lasting performance.