Table of Contents

Benefits of Using Water Pipe Quick Connection Fittings

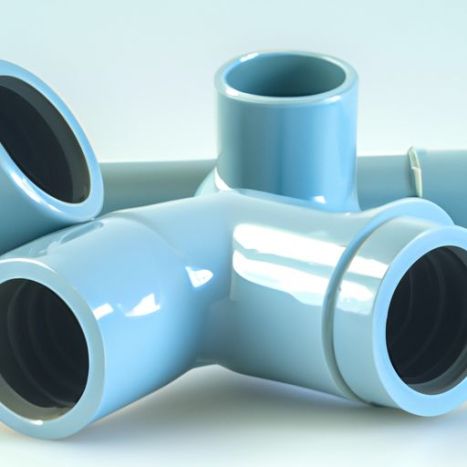

Water pipe quick connection fittings have become increasingly popular in the plumbing industry due to their ease of use and efficiency. These fittings are designed to provide a secure and reliable connection between water pipes without the need for soldering or welding. One of the main benefits of using water pipe quick connection fittings is the time and labor savings they offer. Traditional methods of connecting water pipes, such as soldering or welding, can be time-consuming and require specialized skills. With quick connection fittings, pipes can be easily joined together in a matter of minutes, reducing installation time and labor costs.

In addition to saving time and labor, water pipe quick connection fittings also offer a high level of versatility. These fittings are available in a wide range of sizes and configurations, making them suitable for a variety of applications. Whether you are working on a residential plumbing project or a large-scale industrial installation, quick connection fittings can provide a reliable and efficient solution. Furthermore, quick connection fittings are designed to be easily disassembled and reassembled, allowing for quick and convenient repairs or modifications to the plumbing system.

Another key benefit of using water pipe quick connection fittings is their durability and reliability. These fittings are made from high-quality materials, such as plastic or metal, that are resistant to corrosion and wear. This ensures that the fittings will maintain a secure connection over time, even in harsh environmental conditions. Additionally, quick connection fittings are designed to provide a leak-proof seal, reducing the risk of water damage and ensuring the integrity of the plumbing system.

Another key benefit of using water pipe quick connection fittings is their durability and reliability. These fittings are made from high-quality materials, such as plastic or metal, that are resistant to corrosion and wear. This ensures that the fittings will maintain a secure connection over time, even in harsh environmental conditions. Additionally, quick connection fittings are designed to provide a leak-proof seal, reducing the risk of water damage and ensuring the integrity of the plumbing system.

Quick connection fittings are also known for their ease of installation. Unlike traditional methods of connecting water pipes, which require specialized tools and equipment, quick connection fittings can be installed using simple Hand Tools. This makes them ideal for DIY enthusiasts or homeowners looking to tackle plumbing projects on their own. Additionally, quick connection fittings do not require any additional sealants or adhesives, further simplifying the installation process.

In conclusion, water pipe quick connection fittings offer a wide range of benefits that make them an attractive choice for plumbing projects of all sizes. From time and labor savings to versatility and durability, these fittings provide a reliable and efficient solution for joining water pipes. Whether you are a professional plumber or a DIY enthusiast, quick connection fittings can help you complete your plumbing project quickly and effectively. Consider using water pipe quick connection fittings for your next plumbing installation and experience the many benefits they have to offer.

How to Properly Install Butt Welded Elbow Fittings for Water Pipes

Butt welded elbow fittings are essential components in water pipe systems, as they allow for changes in direction and angle of the pipes. Proper installation of these fittings is crucial to ensure a leak-free and efficient water supply system. In this article, we will discuss the steps involved in properly installing butt welded elbow fittings for water pipes.

First and foremost, it is important to select the right type and size of butt welded elbow fitting for your water pipe system. The fitting should be compatible with the material and diameter of the pipes you are working with. It is recommended to consult with a professional or refer to the manufacturer’s guidelines to ensure you are using the correct fitting for your specific application.

Before beginning the installation process, make sure to thoroughly clean and prepare the ends of the pipes that will be connected to the elbow fitting. Any dirt, debris, or corrosion on the pipe ends can prevent a proper seal and Lead to leaks. Use a pipe cleaner or sandpaper to remove any contaminants and ensure a smooth surface for welding.

Next, carefully align the pipes with the elbow fitting and mark the welding points. It is crucial to ensure that the pipes are properly aligned to prevent any misalignment or uneven welding, which can compromise the integrity of the connection. Use a marker or Chalk to make clear and precise markings on both the pipes and the fitting.

Once the pipes are aligned and marked, it is time to weld the elbow fitting to the pipes. Make sure to follow the manufacturer’s instructions for welding techniques and settings to achieve a strong and secure bond. Use a welding machine or torch to heat the pipes and fitting to the appropriate temperature for welding, and then apply the welding material to create a seamless connection.

After the welding process is complete, allow the connection to cool and inspect it for any signs of defects or leaks. It is important to conduct a pressure test on the newly installed elbow fitting to ensure that it can withstand the water pressure in the system without any issues. If any leaks or weaknesses are detected, make the necessary repairs or adjustments before putting the system into operation.

In conclusion, proper installation of butt welded elbow fittings for water pipes is essential to ensure a reliable and efficient water supply system. By selecting the right fitting, preparing the pipes correctly, aligning them accurately, and welding them securely, you can create a strong and leak-free connection that will last for years to come. Remember to follow the manufacturer’s guidelines and conduct thorough inspections to guarantee the quality and integrity of the installation. With these steps in mind, you can confidently install butt welded elbow fittings for your water pipe system with ease and precision.